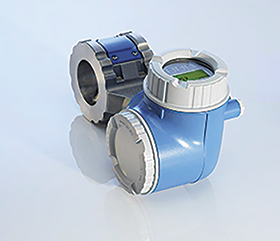

The Endress+Hauser inline measuring devices, the Proline Teqwave MW 300 and the Proline Teqwave MW 500, determine the total solids content of wastewater directly through microwave transmission. This is considerably less time consuming than the process of determining total solids content in a laboratory. The continuously available measured values and short response times mean that the process from primary sludge to dewatered sludge can now be optimised and problematic operating conditions can be detected early.

One of the challenges wastewater plant managers face is controlling the ever-increasing operational costs. A key component of this is monitoring the total solids content in the different process steps within the wastewater plant. A continuously available total solids measurement makes it possible to optimise the separation of the solid and liquid components in the process. It also increases the operational compliance of the process. Here are some of the applications:

Primary clarifier

Primary sludge settles on the bottom of the primary clarifier and is pushed by a scraper into a collection chamber. It then gets pumped into the sludge treatment facility. This usually happens on a time-based control, during which the current total solids content of the sludge mixture is unknown. As a result, the water portion may be significantly increased due to excessive pumping cycles, making the later phase separation difficult.

With the Teqwave MW continuously determining the total solids content, pump operations can be optimised to avoid excess water being pumped to the sludge treatment plant. When a defined threshold value is reached, the pump is switched off. This optimises pump performance and saves energy. The polished measuring tube reduces buildup and, thanks to Endress+Hauser’s Heartbeat technology, the functional integrity of the device can be verified at all times. This means that the calibration intervals can be extended and thus the process availability increased.

Digester

Raw sludge coming from the primary clarifier and biological treatment reactor is concentrated into a thicker sludge product. To achieve this, flocculants are added to the process. This ensures that smaller particles are combined into larger flakes which can be separated more easily from the liquid portion of the mixture. The flocculant is dosed according to experience values and regular laboratory analyses of the total solids content. In the digester, the stabilisation and reduction of the sludge quantity takes place.

Dewatering

The dewatering process is designed to draw as much water as possible from the thickened, but still fluid, sludge before disposal. It is important to reduce weight-based transport costs before disposal. Flocculants are introduced before sludge enters the centrifuge or belt press to improve the clarity of the concentrate. At the same time, they also increase capacity and significantly increase the total solids content.

For more information contact Endress+Hauser South Africa,

© Technews Publishing (Pty) Ltd | All Rights Reserved