End-user details

Name: Paul Roux

Designation: Software Technician

Company: Namakwa Sands

Phone: +27 (0)27 217 3321

E-mail: [email protected]

SI details

Name: Jan Hendrik Rust

Designation: Project Engineer

Company: Adroit Technologies

Phone: +27 (0)11 658 8100

E-mail: [email protected]

Product details

Product name and version: Adroit 7

Vendor: Adroit Technologies

Phone: +27 (0)11 658 8100

E-mail: [email protected]

URL: www.adroit.co.za

Application details

Location: Brand se Baai, Western Cape + Koekenaap, Western Cape

Industry: Mining

Application: Mineral processing

Server OS: Windows Server 2003 & 2008

Client OS: Windows XP Pro & Windows 7

Application statistics

Tag count: Mining site: 19 900; Mineral separation plant: 43 000

Updates per day: Mining site: 140 400 000 (6500 tags per 4 seconds); Mineral separation plant: 194 400 000 (9000 tags per 4 seconds)

Front ends: 72 000 DIO, 16 900 AIO local I/O across 12 * Mitsubishi Q-series PLCs

Licences: Mining site: 6 * 25000 scan point licences; Mineral separation plant: 2 * unlimited scan point licences

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

The project comprised the upgrade of two interconnected Adroit systems. The mine site is split into 3 sections and each section utilises 2 servers in a cluster configuration with a total of 17 viewnodes connected to the servers. The mineral separation plant utilises 2 servers in a cluster configuration with a total of six viewnodes connected to the servers.

Q: What was the primary motivation for the project?

To upgrade the existing server hardware and to upgrade the scada software from Adroit 5 to Adroit 7 in order to utilise newer Adroit features such as Adroit Alarm Management, auditing, configuration of bulk I/O, Windows 2008 Server and Windows Vista support, improved Mitsubishi PLC communication and the option to switch to web client interface.

Q: What were the main goals established for the project?

To accomplish the upgrade without disrupting the production process.

Licensing, maintenance & support

Q: What upgrade agreements are in place for this application?

A site wide licensing option was taken with a 3-year technology and maintenance agreement. The technology agreement allows us to use the latest software in the Adroit Technologies suite for 3 years. During these 3 years we can add more remote clients, scan points and value-adding plug-ins like Alarm Management and OEE.

Q: How is the after-sales support handled on this particular application?

Adroit has a very good support service where if we have a problem we can either phone their support desk or send an email. Their response is always very good. If we really have a crucial emergency they accommodate us very quickly. The 3-year technology and maintenance agreement includes an annual site visit.

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

Yes. The system is integrated onto its own process network connected to the PLCs. The clients have full control over their specific plants. I.e. remote clients of plant A have full control over plant A processes and may view, but not control, plants B and C. However, a user with sufficient rights (the Software Technician) can control across the network.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

Yes. The application operates in conjunction with a third-party mill optimisation application written by SGS South Africa.

Management reporting and integration

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes. Normal Adroit proprietary logging is used. Data is logged either on change or triggered and is stored according to the time line specified by the client requirements.

Q: Is the system integrated with an MES/ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

No.

Q: Have any production benchmarking tools been configured as part of the scada system?

We have configured the system to provide a dashboard where actual figures are displayed continuously with comparative best and worst targets.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No.

Q: Are you currently using tablet PCs or mobile phones to interact with the scada system?

No.

End-user conclusion

Q: In the procurement decision making process was the Total Cost of Ownership (TCO) considered? If so, what were the primary TCO considerations that influenced the product selection?

N/A.

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

The earlier version of Adroit had already proven itself reliable and it was decided to do the upgrade to version 7.

Q: What single feature most impresses you about the product now that it is in operation?

Ease of use.

Q: What impresses you most about the architecture?

The Adroit cluster redundancy, which allows two servers to run in parallel; one in Master mode and one in Standby, both communicating to the PLCs. This allowed us to first replace the server that was in standby mode, while all the remote clients were connected to the master. When finished we would run the new server in parallel with the old server but in standby. We would then make the new server Master, and replace the old server. This meant that we did not have any production downtime during the upgrade.

SI Responses

Project details

Q: Approximately how many man-hours did the scada configuration take?

The upgrade took 80 man-hours.

Q: What human factors were taken into consideration in the HMI design process?

The existing look and feel had to be kept with more information made available to the users in an easy to read interface.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

The client’s existing library was used.

Q: How would you describe the library of graphic images?

Very simple and informative with easily identifiable objects.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

No.

Q: Did you use any video or multimedia technology used in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system?

The Adroit Alarm Management software was used together with the client’s existing standards and procedures.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

Each new server was first run in standby mode in parallel with the existing master. Then during the daytime we would run the new server as master to test under normal operations.

Q: What are the key physical communication layers and communication protocols employed in the system?

Communication between local clients, servers and PLCs is via Ethernet TCP/IP over copper. Communication between the different plants is Ethernet TCP/IP over fibre.

Q: What levels of redundancy are incorporated in this scada application?

On the server side, Adroit Cluster servers were setup. Client interfaces are mutually redundant since each client interface can view the whole plant.

Q: What specific custom code or scada scripts were written for this project?

None.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Windows domain security was used for operator authorisation and role management on the remote clients.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks.

Yes, this was configured with the help of the clients IT department. Specified users can view the plant from their office PC.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

An anti virus product – further information withheld by client.

Q: What configuration backup and data archive backup methodologies have been adopted?

This was incorporated with the IT department backup strategy, which includes weekly tape drive backups and also backs up to an off-site backup system.

Q: Did you use any integrated or third-party configuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

The standard Adroit propriety logging is very easy to use and incorporates a bulk configuration mode.

Q: What impresses you the most about the engineering / configuration aspects of the product now that it is in operation?

The ease of use of the software. How simple and easy it was to upgrade two large process sections with remote clients over 5 days and not have any interruptions to the process operations.

Q: What impresses you most about the architecture?

The architecture of the product makes configuring of a system very simple.

Vendor responses

Product

Q: Vendor comments on product/modules?

The latest version of Adroit is Adroit 7 and that is the version installed on this project.

Adroit 7 offers improved performance and Alarm management for optimisation of alarms.

Operating systems/VMware

Q: Vendor comments on operating systems

All products are developed on a Microsoft platform. (Microsoft Visual Studio) for .Net platforms.

Licensing, maintenance & support model

Q: What sort of licensing agreement options are offered?

The client may purchase only the modules required.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Licence is once-off bought for a specific software version.

Q: What upgrade agreements are offered?

All Adroit revisions (7.01 to 7.2) are free to licensed users of that release (7). New releases are billable.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

We offer free telephonic and e-mail support. A support engineer can be requested for site assistance. We also offer Internet remote connection, but very few clients use this option because of the risk involved. We also offer a technology and maintenance agreement where clients can specify the frequency and duration of site visits by an Adroit engineer.

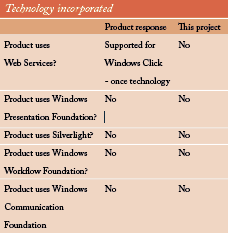

Technology incorporated

Management reporting and integration

Q: What native historical data reporting options are available?

Adroit uses Adroit SCADA Intelligence, which is built on the Microsoft SQL Server platform. This platform includes Microsoft Reporting Services, Analysis Services and SQL.

Q: What product specific interface does the product have iro well-known MES packages?

None.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

None. This capability forms part of Adroit’s Mitsubishi Adroit Process Suite (MAPS).

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

The Windows platform security model is inherited.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

* Active Cluster architecture – Delivers redundancy and consequent reliability.

* Resource friendly and scalable – A single server can handle large systems (>1 000 000 I/O with logging, trending and alarming) reducing hardware infrastructure investment and maintenance.

* On-line development – No need to shut down or interrupt the production process when making changes.

Centralised configuration – Allows users to configure and modify graphics or agents from any computer on the network.

* Once-off payment for software revisions – Cost effective.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved