End-user details

Name: Johan Saunders

Designation: Technical Advisor

Company: Pretoria Portland Cement (PPC)

Phone: +27 (0)12 377 7386

E-mail: [email protected]

SI details

Name: Ernie Koopmans

Designation: Director

Company: Quad Automation

Phone: +27 (0)11 315 2408

E-mail: [email protected]

Product details

Product name and version: ArchestrA System Platform 3.1

Vendor: Invensys Wonderware

Phone: +27 (0)11 607 8100

E-mail: [email protected]

URL: www.wonderware.co.za

Application details

Location: Hercules, Pretoria

Industry: Cement manufacturing

Application: Materials handling

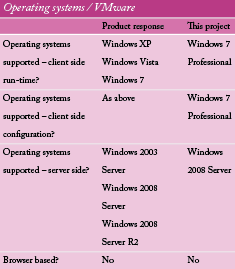

Server OS: Windows 2008 Server

Client OS: Windows 7 Professional

Application statistics

Tag count: 30 000

Updates per day: 22 500 000

Front ends: 3000 DIO and 1000 AIO across 6 * PLCs (4 * Siemens S7-400, 2 * S7-300), 160 * Siemens Simocode motor management devices, 12 * Process Automation Unipro Scales, 12 * SEW VSD Drives, 12 * Siemens DC Drives

Licences: 1 * 50K ArchestrA System Platform, 8 * InTouch View Nodes

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

The existing systems were more than 30 years old and required upgrading. The upgrade included the replacement of conventional control desk and chart recorders. Network infrastructure had to be established and relay control philosophy captured to software.

Q: What was the primary motivation for the project?

Maintenance support was unavailable on obsolete equipment and the existing relay controls and data acquisition could not easily be expanded. Computerised archiving of events and process recording were not possible.

Q: What were the main goals established for the project?

1. Create a centralised control room consolidating the functionality of existing standalone control stations.

2. Achieve effective measurement of KPIs using plant-wide process historian.

3. Limit plant downtime to one 5-week shutdown per year.

Licensing, maintenance & support

Q: What upgrade agreements are in place for this application?

Upgrades are covered through an annual software renewal at 18% of licence list price.

Q: How is the after-sales support handled on this particular application?

Support is covered under a paid annual support agreement, which includes telephonic and e-mail support.

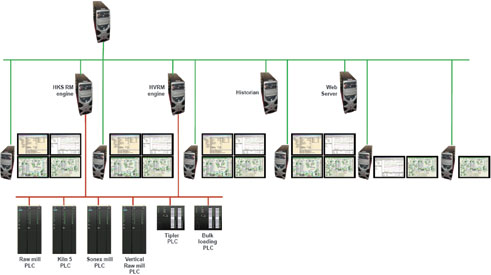

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

Yes. Intranet clients have access to real-time and historical trends and reports via web server functions.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

No.

Management reporting and integration

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes. The Wonderware System Platform is used for archiving all process data. The ActiveFactory tool set provides add-ons to Excel for localised reporting. MS Reporting Services in conjunction with Wonderware Information Server provides a web portal for plant data.

Q: Is the system integrated with an MES/ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

No.

Q: Have any production benchmarking tools been configured as part of the scada system?

One of the management information reports logs the number of stoppages per major process unit and summarises utilisation against stoppage causes, this KPI is under continuous evaluation.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No.

Q: Are you currently using tablet PCs or mobile phones to interact with the scada system?

No.

End-user conclusion

Q: In the procurement decision making process was the Total Cost of Ownership (TCO) considered? If so, what were the primary TCO considerations that influenced the product selection?

No.

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Inherent object orientation, hierarchical structures with adoption of ISA-95 standards, integrated graphics and library set.

Q: What single feature most impresses you about the product now that it is in operation?

Self-sustaining and seamless upgrade paths.

Q: What impresses you most about the architecture?

The model based, object oriented, templated achitecture allows us to define all aspects of the processes and physical assets including logic and scripts, how data will be acquired, how alarms are defined, system security and user roles, and external interfaces. ArchestrA objects and templates simplify the generation of standards and a set of library objects to provide a uniform HMI interface across the facility.

SI Responses

Project details

Q: Approximately how many man-hours did the scada configuration take?

800 man-hours.

Q: What human factors were taken into consideration in the HMI design process?

Four screens were used for operator navigation and multiple plant areas carefully considered reducing clutter and simplifying routing. No flashing icons were used. Nuisance alarm suppression was provided.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Images were created from scratch per cement typicals.

Q: How would you describe the library of graphic images?

Good.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

No.

Q: Did you use any video or multimedia technology used in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system?

Alarm filters provide for area selections and a global alarm list provides rapid navigation to detail area.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

The System was tested under full load in a simulated environment. System faults were systematically introduced and their effect on the system monitored.

Q: What are the key physical communication layers and communication protocols employed in the system?

1 GB Ethernet TCP/IP scada LAN over copper and 1,5 MB Profibus IO LAN in a redundant ring over fibre.

Q: What levels of redundancy are incorporated in this scada application?

A redundant I/O server was installed.

Q: What specific custom code or scada scripts were written for this project?

Custom code/scripts were written for alarm handling, displays and navigation, security and data protection.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Security and roles are defined within the Wonderware System Platform and after deployment are inherent across multiple stations.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks?

Network segregation was achieved by physical segregation and managed switches.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

None. The process control network is physically isolated from other networks.

Q: What configuration backup and data archive backup methodologies have been adopted?

Configuration data is manually backed-up for disaster recovery. Historian data is automatically archived to alternate network storage drive monthly.

Q: Did you use any integrated or third-party configuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

The ability to maintain a uniform operator interface through the deployment of library standards.

Q: What impresses you most about the architecture?

It enables all scada system components to be configured and managed from one user interface.

Vendor responses

Product

Q: Vendor comments on product/modules?

The current version of the ArchestrA System Platform is 2012 and the on-site version ArchestrA System Platform 3.1.

Modules and versions included: Application Server 2012, InTouch 2012, Historian Server 2012, Device Integration Server 2012, and Information Server Portal 2012.

Operating systems/VMware

Q: Vendor comments on operating systems

Integration and support with Microsoft Windows operating systems, Visual Studio® development system, SQL Server, BizTalk Server, SharePoint, Microsoft Office, Internet Explorer, Microsoft Remote Desktop Services, Smart Card authentication and Hyper-V/VMware virtualisation.

Licensing, maintenance & support model

Q: What sort of licensing agreement options are offered?

The ArchestrA System Platform consists of multiple product licence files. There are three types of parts associated to the ArchestrA System Platform concept:

1. ArchestrA System Platform – includes: Wonderware Application Server (AS) IO (Galaxy) plus a number of AS Platform Licenses, Wonderware Historian Server, Information Server and Device Integration Server.

2. ArchestrA System Platform Additions for expanded solutions – includes: Device Integration Server, Historian Standard and Enterprise Edition Servers, Information Server and additional Application Server Platforms for existing InTouch nodes, Automation Object nodes or for Terminal Servers running instances of InTouch Terminal Services Editions.

3. Wonderware Clients: InTouch for ArchestrA System Platform with or without Wonderware Historian Client, Information Server Clients, Wonderware Historian Clients and Client Access Licences (CAL).

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Sold outright.

Q: What upgrade agreements are offered?

Annually renewable Customer FIRST support agreements include patches, service packs and free upgrades of all licences.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Annually renewable Customer FIRST support agreements include technical support. Invensys Sentinel Services provides remote monitoring of system events and server performance. SIs also play a vital role in aftersales on-site support.

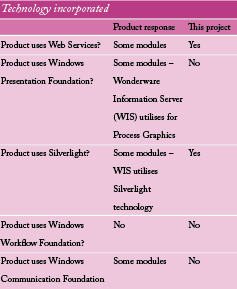

Technology incorporated

Management reporting and integration

Q: What native historical data reporting options are available?

The ArchestrA System Platform includes Wonderware Historian Server and Information Server Portal as a web information portal. Historian is an extension to Microsoft SQL Server. Wonderware Information Server provides modular data reporting and analysis tools to increase profitability with immediate access to key performance indicators (KPIs), SPC, downtime and equipment efficiency information, live data calculations, event and alarm notifications and historical data.

Q: What product specific interface does the product have iro well-known MES packages?

SAP and generic interfaces using such technologies and OPC, SQL, XML, OLE DB/ADO and proxy objects.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

None.

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

ArchestrA System Platform can either use native security or extend the Microsoft Windows security model down to the physical equipment layer, enabling IT-friendly, industrial-strength and single sign-on data security at the lowest possible level of granularity.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

* Industrial Application Services – provides the essential industrial domain services you need, which are not found in commercial operating systems.

* Common Infrastructure Model – Provides a logical representation of the processes and physical equipment controlled and supervised. Object orientation and object templates facilitate standardisation of visualisation and operation.

* Scalability – Build once and deploy everywhere – saving up to 70% in engineering costs.

* Unrivalled software and device connectivity – Users can connect data sources to applications and connect with 32–bit I/O servers for hundreds of the most popular control devices, PLCs, RTUs and DCSs.

* Virtualisation, high availability and disaster recovery – System Platform can be configured to operate in multiple failover modes to ensure redundancy in system operation and data flow. System Platform supports Microsoft’s Hyper–V virtualisation technology. Redundant systems running on Hyper–V servers can be located in separate physical locations so users can recover faster from a site disaster. VMware is also supported for virtualisation and flexible application administration.

© Technews Publishing (Pty) Ltd | All Rights Reserved