End-user details

Name: Alain Blatti

Designation: MES Tech Lead

Company: Aberdare Cables

Phone: +27 (0)82 320 3110

E-mail: [email protected]

SI details

Per end user

Product details

Product name and version: Proficy CIMPLICITY HMI/SCADA V8.2

Vendor: GE Intelligent Platforms

Phone: +27 (0)11 237 0000

E-mail: [email protected]

URL: www.ge-ip.com

Application details

Location: Pietermaritzburg, Port Elizabeth, Johannesburg

Industry: Cable manufacturing

Application: Manufacturing

Server OS: Windows Server 2008

Client OS: Windows Server 2008

Application statistics

Tag count: Approx 36 000 (12 000 per site * 3 sites)

Updates per day: 3 456 000 (40 production-based tags per second)

Front ends: Pietermaritzburg: Omron PLCs; Port Elizabeth: Siemens PLCs; Johannesburg: Klockner Muller PLCs

Licences: Proficy Cimplicity Proserver SCADA, Proficy CIMPLICITY Clients, Proficy Historian, Proficy Plant Applications Efficiency Server, Proficy Plant Applications Quality Server, Proficy Plant Applications Production Management Server, Proficy Real Time Information Portal

End-user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

The Proficy Cimplicity SCADA provides the line operators with production data from the Proficy Plant Application MES system. Scheduled orders are displayed and operators select orders to be processed and link available material to the order. The scada provides the operator with machine setup parameters and checks that the correct material is loaded as per the order job card. The system captures machine operating data for material management, quality, and production information and provides the operator with real-time production order information. The system replaced a Diames system.

Q: What was the primary motivation for the project?

To replace an existing system that was no longer supportable.

Q: What were the main goals established for the project?

1. To integrate real-time manufacturing metrics with SAP.

2. To reduce waste through real-time visibility and material management.

3. To improve finished product quality.

Licensing, maintenance & support

Q: What upgrade agreements are in place for this application?

None.

Q: How is the after-sales support handled on this particular application?

Local support billable on a per request basis.

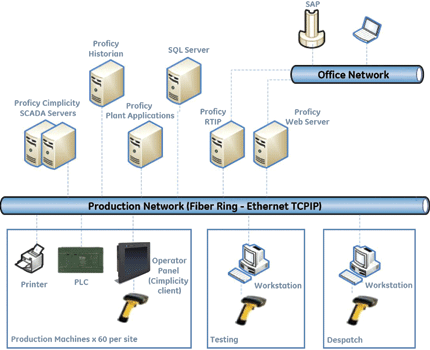

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

Yes. 180 clients across 3 sites interface with the server through the local network for full remote control. Internet services are available through the GE WebSpace server.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

No.

Management reporting and integration

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

The application uses Proficy Historian as the production and manufacturing data archive. Standard reports as well as custom reports are generated in conjunction with MS Reporting Services on top of an MS SQL historian.

Q: Is the system integrated with an MES/ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

Yes. The scada server interfaces with the Proficy Plant Application server through standard TCP/IP. The Plant Application server interfaces with SAP.

Q: Who performed this management system integration and was any additional software development needed to accomplish this?

GE Intelligent Platform Professional Services integrated the systems utilising the standard interfacing toolset.

Q: Have any production benchmarking tools been configured as part of the scada system?

The system is configured to provide a production dashboard indicating real-time machine production status relative to the planned status.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No.

Q: Are you currently using tablet PCs or mobile phones to interact with the scada system?

No.

End-user conclusion

Q: In the procurement decision making process was the Total Cost of Ownership (TCO) considered? If so, what were the primary TCO considerations that influenced the product selection?

The decision was based on ease of use, upgrade path, open standards and long-term support.

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Open standards interface to different vendor PLCs.

Q: What single feature most impresses you about the product now that it is in operation?

The ability to make configuration changes on the fly.

Q: What impresses you most about the architecture?

The ease with which the architecture scales from a simple client-server to a multi-tier application capable of installation on a web farm.

SI Responses

Project details

Q: Approximately how many man-hours did the scada configuration take?

250 man-hours development time for scada screens.

Q: What human factors were taken into consideration in the HMI design process?

Ease of operator entry and data display.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Standard library.

Q: How would you describe the library of graphic images?

Comprehensive.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

Utilised ActiveX for standard MES system displays.

Q: Did you use any video or multimedia technology used in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system?

Scada alarm functionality was not used.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

Followed manufacturer’s recommended architecture and server requirements, and implemented based on Global Implementation Methodology as prescribed by the Project Management Methodology v1.7 (PMM), the Project Management Institute – Good Automation Manufacturing Practices v5 (GAMP).

Q: What are the key physical communication layers and communication protocols employed in the system?

The Production Network consists of a fibre Ethernet TCP/IP ring with copper cable drops from the switches to the servers, PLCs and operator terminals (CIMPLICITY Clients).

Q: What levels of redundancy are incorporated in this scada application?

None.

Q: What specific custom code or scada scripts were written for this project?

Some ActiveX components were written to supersede the standard ones to be more production information specific.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Application specific, linking security to an external database.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks.

No.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

Own control system domain separate from business LAN and firewalled at interconnection.

Q: What configuration backup and data archive backup methodologies have been adopted?

Backups are run locally and then the backup file is moved during low bandwidth usage to an external location.

Q: Did you use any integrated or third party configuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

We are using MS Reporting Services and bypass the standard template reporting tool.

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

It is easy to grow the existing system using simple export import mechanisms.

Q: What impresses you most about the architecture?

The use of open standards, wide range of drivers and the ability to easily upgrade the application with newer revisions.

Vendor responses

Product

Q: Vendor comments on product/modules?

* The current version of CIMPLICITY is v8.2 and on site is v8.1.

* Proficy CIMPLICITY HMI/SCADA is a Client/Server based HMI/SCADA solution.

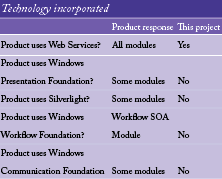

* Proficy SOA provides a powerful enabling Service Oriented architecture for business processes.

* Alarm Cast provides the capability to provide notification of CIMPLICITY events to a variety of different Internet, mobile and PC media including pagers, SMS, e-mail, ODBC, UCP and more.

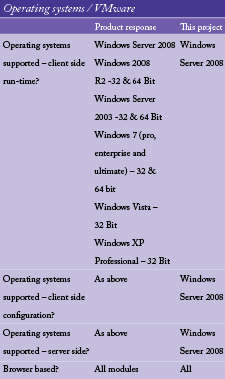

Operating systems/VMware

Q: Vendor comments on operating systems?

Microsoft IIS, Windows Mobile, Mobile OS, iOS & iPAD Client support.

Licensing, maintenance & support model

Q: What sort of licensing agreement options are offered?

* Licence is tag based with Runtime and Development server options. Clients are purchased separately as per user requirements.

* All systems include as standard Graphics, Alarm Management, Trending, Basic Control Engine (Visual Basic scripting), System Management Utilities, ODBC Data Logging, DDE Client, Advanced DDE Client, OPC Client and GE Intelligent Platforms PLC communications.

* CIMPLICITY Pro Server is a bundled package including multiple drivers and the following options: Action Calendar, Recipe, System Sentry, SQL 1 Client User, Terminal Services Single User, WebView Single User, Digital Graphic Replay, Marquee Driver, and Statistical Process Control.

* Other optional modules include:

- Alarm Cast Advanced/Enterprise

- Redundancy

- A comprehensive list of dedicated drivers for third-party data providers

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Licence is a once-off purchase for a particular version and can be upgraded to the latest version through Global Care annual subscription.

Q: What upgrade agreements are offered?

Patched and version upgrades are available at no additional cost if user purchases the Global Care annual maintenance option.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Support is available under a paid annual support agreement and includes desktop remoting, e-mail and telephonic support.

Technology incorporated

Management reporting and integration

Q: What native historical data reporting options are available?

Proficy Real Time Information Portal (RTIP) provides reporting functionality for Proficy CIMPLICITY historical data. The application incorporates built-in interfaces that use MS Reporting Services on top of an MS SQL historian.

Q: What product specific interface does the product have iro well-known MES packages?

The Proficy Open Enterprise module is SAP certified and open to connect with third-party products utilising B2MML (Business To Manufacturing Markup Language).

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

The scada and PLC applications can be managed with the Proficy Change Management option for revision control. Proficy Process Solutions CIMPLICITY provides system coding and configuration for the PAC RX3i, RX7i and PAC 8000 hardware platforms.

Security and data protection

Q: If the scada system generates application files that are transferred to the PLC, how are Stuxnet style PLC virus attacks prevented?

N/A.

Q: What authentication, authorisation and role management models are available for the runtime environment?

Windows domain users are mapped to roles and resources in CIMPLICITY through Windows Domain integration.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

* Digital Graphical Replay (DGR) – Enables users to identify and troubleshoot issues and prevent repeat occurrences by allowing users to replay and analyse past events in slow motion, real-time or up to 100x the speed.

* GlobalView 2.2 – Provides access to views via supported PC based web browsers, UNIX and Linux browsers, and mobile clients.

* Microsecond Time Stamps – Enables detailed Sequence of Event (SOE) analysis.

* Alarm Change Approval – Provides support for requiring approvals (Electronic Signature) for setpoint changes in support of regulatory compliance for NERC in the energy industry, Part 11 in Life Sciences, or other regulated industries.

* Historian Expression Processor – Facilitates the use of historical data to animate screen objects, or as part of the trending to provide statistical analysis for enhanced decision making.

© Technews Publishing (Pty) Ltd | All Rights Reserved