End-user details

Name: Details withheld at reviewer request

SI details

Name: Simon Somerset

Designation: Project Engineer

Company: Directech

Phone: +27 (0)11 708 2202

E-mail: [email protected]

Product details

Product name and version: COPA-DATA zenon 6.51

Vendor: Anytech

Phone: +27 (0)11 708 1992

E-mail: [email protected]

URL: www.anytech.co.za

Application details

Location: Randfontein

Industry: Mining

Location: Blantyre Malawi

Application: Mineral processing

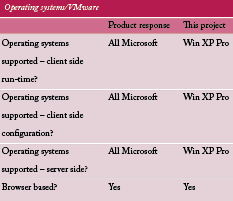

Server OS: Windows XP Pro

Client OS: Windows XP Pro

Application statistics

Tag count: > 4000

Updates per day: 4000

Front ends: 1 * CTi PLC

Licences: 4096 tag zenon licence with reports, historian and extended trends

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

The scada installation was a replacement for an old system that did not work. The main purpose of the scada is to provide management with information on the operation of the milling circuits.

Q: What was the primary motivation for the project?

To provide a live overview of the milling process and record equipment downtime.

Q: What were the main goals established for the project?

To reduce downtime and improve response time to error situations.

Licensing, maintenance & support

Q: What upgrade agreements are in place for this application?

None – Client will purchase as required.

Q: How is the after-sales support handled on this particular application?

End user is contacted on a regular basis, and training is supplied to help end user keep up to date.

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

No

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

No

Management reporting and integration

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes

Q: Is the system integrated with an MES/ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

No

Q: Who performed this management system integration and was any additional software development needed to accomplish this?

N/A

Q: Have any production benchmarking tools been configured as part of the scada system?

No

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No

Q: Are you currently using tablet PCs or mobile phones to interact with the scada system?

No

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Competitive price and capability demonstration by SI.

Q: What single feature most impresses you about the product now that it is in operation?

No programming required, only parameterisation, which makes it easy to understand.

Q: What impresses you most about the architecture?

Ease of upgrade and large number of drivers available.

SI Responses

Project details

Q: Approximately how many man-hours did the scada configuration take?

40 man-hours.

Q: What human factors were taken into consideration in the HMI design process?

Active elements such as buttons were sized to make them easy to operate on the touch screen.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Standard library.

Q: How would you describe the library of graphic images?

The standard library has a wide variety of images and the user can also build his own images or import new ones.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

No.

Q: Did you use any video or multimedia technology used in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system?

Pop-up alarms were used to display mill stoppages. An email notification system is being implemented to alert technicians to critical alarms.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

None.

Q: What are the key physical communication layers and communication protocols employed in the system?

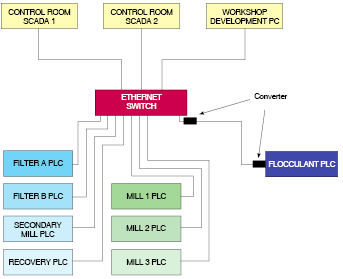

Ethernet TCP/IP over copper.

Q: What levels of redundancy are incorporated in this scada application?

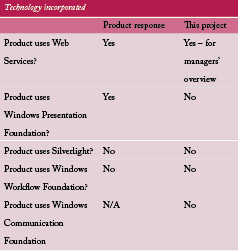

Some redundancy is inherent through providing the manager’s overview via a Web server.

Q: What specific custom code or scada scripts were written for this project?

Some Microsoft VSTA (Visual Studio Tools for Applications) scripts were written for button actions.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

The zenon system has its own role management.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks.

The system is standalone.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

N/A.

Q: What configuration back-up and data archive backup methodologies have been adopted?

None currently.

Q: Did you use any integrated or third-party configuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

Very user friendly.

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

It is an easy to use system with quick engineering and planning.

Q: What impresses you most about the architecture?

It incorporates all the drivers needed for any plc.

Vendor responses

Product

Q: Vendor comments on product/modules?

The current version is v7.00 and that used on the project was v6.51.

Modules available include: Historian, Extended Trend, Report Generator, Batch Control, Recipe Group Manager, SQL Export, Message Control, Industrial Performance Analyzer, PLC Diagnosis, Industrial Maintenance Manager, Process Gateway, Automatic Line Colouring, Production & Facility Scheduler, Historian SQL server, Text to Speech, Energy Management System, SAP Interface.

Operating systems/VMware

Licensing, maintenance & support model

Q: What sort of licensing agreement options are offered?

Modules can be purchased separately or one licence, which includes all modules, can be purchased.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Both are offered.

Q: What upgrade agreements are offered?

Upgrades are charged for. They can be offered as part of an annual charge or on an as needed basis.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

There is an international support team, local support and system integrators available for support.

Technology incorporated

Management reporting and integration

Q: What native historical data reporting options are available?

Reporting is provided through Microsoft Report Builder.

Q: What product specific interface does the product have iro well-known MES packages?

The zenon ERP interface is SAP certified and provides bi-directional communication with SAP.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

N/A

Security and data protection

Q: If the scada system generates application files that are transferred to the PLC, how are Stuxnet style PLC virus attacks prevented?

N/A

Q: What authentication, authorisation and role management models are available for the runtime environment?

Authentication, authorisation and role management are incorporated into zenon. Users may have multiple roles assigned to them. Up to 128 roles can be configured.

© Technews Publishing (Pty) Ltd | All Rights Reserved