ArchestrA System Platform 2012 and Workflow 2012 empower workforces to operational excellence through tighter integration and a virtual computer infrastructure.

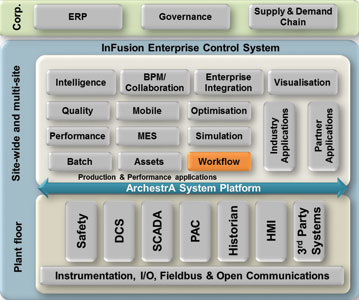

Invensys Operations Management has announced the release of its ArchestrA System Platform 2012 and ArchestrA Workflow 2012 software offerings. ArchestrA System Platform and ArchestrA Workflow provide the core integration and collaboration platform inside the company’s InFusion Enterprise Control System and, when used in combination, offer a broad range of automation and information functionality that allows users to empower their personnel, processes and systems for real-time business optimisation.

ArchestrA System Platform 2012 provides a single, scalable and open platform for the entire spectrum of automation and information applications, addressing the business and functional needs of industrial automation, operations and information personnel. Its plant-model-based, integrated configuration environment provides a logical representation of the physical processes being controlled and supervised, enabling rapid configuration and deployment of component-object-based industrial applications. When deployed, the software improves performance, strengthens security and simplifies installation while increasing operator and engineering productivity and efficiency. The software also supports new high-availability disaster recovery implementations using Windows Server Hyper-V virtualisation from Microsoft. In addition, ArchestrA System Platform 2012 software supports all the latest remote desktop services that are part of Windows Server 2008 R2.

Relying on the standards-based ArchestrA architecture, System Platform 2012 also provides tighter integration with ArchestrA Workflow and the Wonderware InTouch HMI software as well as the extensive portfolio of automation and software applications. Together, the improved offerings enable customers to unite their existing automation and IT systems with applications from Invensys, its ecosystem partners and other third-party providers, to function as one, holistic Enterprise Control System.

“With the introduction of ArchestrA System Platform 2012 and ArchestrA Workflow 2012 software, Invensys continues to raise the bar by providing an integrated software platform for developing and deploying industrial automation, visualisation, information and workflow applications across physical and virtualised computing infrastructures,” says Deon van Aardt, MD of Invensys Wonderware Southern Africa.

Today’s manufacturers and processing companies typically operate a range of facilities, all with different automation, monitoring and reporting systems. Managing these legacy systems can be costly and time consuming. ArchestrA System Platform and ArchestrA Workflow software solve this problem through a common infrastructure to develop and maintain industrial applications. These solutions allow users anywhere on the network to design build and deploy industrial workflow, HMI, automation and information applications, while leveraging a powerful combination of re-usable application templates. Not only does this reduce engineering costs, shorten project timetables and enforce automation and operational procedures, it empowers the workforce and strengthens the drive toward real-time business optimisation.

For more information contact Jaco Markwat, Invensys Wonderware, +27 (0)11 607 8100, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved