Reviewer details

Name: Details withheld at reviewer request

SI details

Name: Andre Vuilleumier

Designation: Managing director

Company: Systems Anywhere

Phone: +27 (0)11 024 5490/1

E-mail: [email protected]

Product details

Product name and version: Wonderware System Platform v4.0

Vendor: Wonderware Southern Africa

Phone: 0861 WONDER

E-mail: [email protected]

URL: www.wonderware.co.za

Application details

Industry: Gold mining

Location: Tongon, Côte d’Ivoire

Application: Supervisory and Control system for mining

Server OS: Windows Server 2003 R2

Client OS: Windows XP SP3

Application statistics

Tag count: 4500 I/O points

Updates per day: 6000 discrete tags on change; 4000 analogue tags on change outside deadband. Equates to around 250 MB/day.

Front ends: 3500 discrete I/O and 1000 analog I/O across 11 PLCs

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

Tongon Gold Mine is a greenfields site. The application requirement was to supervise and control the mining process, provide operator interfaces (scada) and reports of day-to-day operations. Additional functional requirements included mill performance optimisation.

Licensing, maintenance and support

Q: What licences have been purchased for this application?

Wonderware System Platform (including Wonderware Historian) is the core foundation in addition to InTouch for System Platform clients and Information Server Reporting clients. A Development Studio licence for end-user configuration is also included.

Q: What upgrade agreements are in place on this application?

Version upgrades are covered under the paid annual Customer First agreement.

Q: How is the after-sales support handled on this application?

Software support is covered under the paid annual Customer First agreement, bundled with 24/7 remote application support offered by Systems Anywhere as part of their annual Maintenance Service Agreement (MSA). The MSA includes remote login facilities to Systems Anywhere engineers.

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

Access to KPIs, plant overview graphics and reports to intranet users is via a web interface.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

Yes. The Systems Anywhere ‘Expert Operator’ is a third-party application developed with the Wonderware Object Toolkit for mill optimisation and control.

Management reporting and integration

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes. The Wonderware Historian is part of the System Platform core software. Historical and real-time trending are displayed on scada operator stations from Historian Client tools (MS Excel add-in). Formal production reporting and ad-hoc analysis are delivered via the Wonderware Information Server web-portal. Formal reporting is generated with the Wonderware Historian client tools and the integrated MS Reporting Services, and then published at predetermined intervals to the Information Server portal.

Q: Is the system integrated with an MES/ERP or other management reporting or control system? (eg, Baan, SAP, SYSPRO…)

No.

Q: Have any production benchmarking tools been configured as part of the scada system?

Benchmarking is provided as part of the formal reporting and provides information such as daily/shift comparison figures and reports.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

Yes. The template/object design by Systems Anywhere engineers includes fields for plant and control system assets (including specifications and location) for easy reference and reporting. The naming convention used in the control system lends itself to the easy identification of assets.

Q: Has any GIS (geographic information systems) functionality been configured in the application?

No.

Q: Are you currently using tablet PCs or mobile phones to interact with the scada system?

No, but we are currently investigating the use of the Wonderware SmartGlance application for mobile reporting on smartphones.

End-user conclusion

Q: In the procurement decision making process was the total cost of ownership (TCO) considered?

No.

Q: What was the predominant feature (or features) that made you decide to purchase this product for this application?

• Expert system.

• ArchestrA total offering.

• Previous successes in the same industry by Wonderware.

• Stability.

• Ease of use and ability to communicate with a vast range of front-end equipment.

Q: What single feature most impresses you about the product now that it is in operation?

The ease with which incorrect parameters can be quickly seen and corrected.

Q: What impresses you most about the architecture?

• Fast and easy deployment to multiple remote stations. One deployment and all sub systems roll out to the new configuration, saving time and errors.

• The Web interface allows more eyes on the system without having to add view node stations.

SI Responses

Project details

Q: Approximately how many man-hours did the scada configuration take?

The entire project spanned 6 months but scada configuration man-hours are not available.

Q: What human factors were taken into consideration in the HMI design process?

User friendly, straightforward and simple to suit all operator levels. Contrasts of pastel colours used on screens are relaxing.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Systems Anywhere’s comprehensive library templates were used, and modified to customer requirements. The SA library was built on the supplied Wonderware library.

Q: How would you describe the library of graphic images?

An extensive collection of graphical symbols that can be used as-is, or modified to form part of company standards.

Q: Did you use any ‘special’ images (eg, photographs, 3D images, specialised dashboards, etc.)?

Yes. An aerial photograph is used as the welcome screen to display the different process sections for easy navigation.

Q: Did you use any video or multimedia technology used in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system?

Alarms are configured per process area relating back to an S95 structure inside the Wonderware environment. Operators can display alarms per process cell, area or plant. Alarms are displayed as lists and also in a Pareto diagram format for easy visual interpretation by the operator (top alarms, total alarms and time in state).

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

During the Thin-Slice at the Systems Anywhere offices, all abnormal conditions were simulated to ensure that the live system would be able to withstand such failures and ensure safe operations.

Q: What are the key physical communication layers and communication protocols employed in the system?

The control system supervisory layer is standard Ethernet TCP/IP. The communication layer between PLC and control system is based on Industrial Ethernet (TCP/IP). Rockwell CIP and DeviceNet were used for drive communications.

Q: What levels of redundancy are incorporated in this scada application?

A pair of Automation Object Servers provide System Platform redundancy for application, alarming, scripting and execution levels.

This also provides store-forward capability to the historian, ensuring that no historical data is lost. Multiple InTouch scada operator nodes provide operator control redundancy. With redundant PLC communication the complete design provides high-availability at all levels.

Q: What specific custom code or scada scripts were written for this project?

None.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Using the ArchestrA security model. Users and roles are defined with different access levels.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks?

Segregation is through physical separation.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

Kaspersky virus protection updates from single point to server (update server has access to Internet for updates).

Q: What configuration backup and data archive backup methodologies have been adopted?

Systems Anywhere SOP defines how and when backups get made.

Q: Did you use any integrated or third party configuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

Phenomenally easy.

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

• Re-usability and roll-out (replication).

• Design once, roll-out many times.

Q: What impresses you most about the architecture?

Freedom of architecture. SI can build and maintain standard for client that can be used at other sites. Customer can take ownership of standards. Open – any certified person can support the system.

Vendor responses

Product

Q: Vendor comments on product/modules?

Available Wonderware products include:

* Development Studio

* Device Integration Servers

* Historian

* Information Server

* InTouch HMI

* Application Server

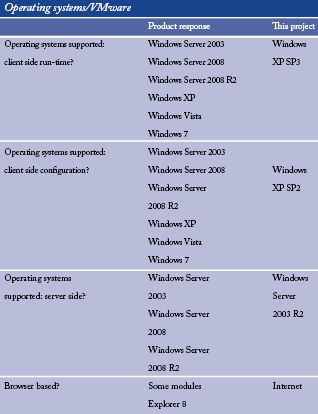

Operating systems/VMware

Q: Vendor comments on OS?

The Wonderware System Platform is a combination of Strategic Application Services built on ArchestrA Technology. It represents multiple closely associated and integrated Wonderware server products as a base for multi-node Supervisory, scada and MES/EMI solutions. Integration and support with Microsoft products including Windows operating systems, Visual Studio development system, SQL Server, BizTalk Server, SharePoint, Microsoft Office, and Internet Explorer.

Licensing, maintenance and support model

Q: What sort of licensing agreement options are offered?

A flexible licensing model is offered depending on client requirements.

Q: Are licences sold outright or subject to periodic (eg, annual) renewal?

Sold outright.

Q: What upgrade agreements are offered?

Upgrades are covered under annual maintenance agreement.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Support is covered under a paid annual support agreement.

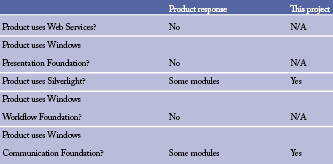

Technology incorporated

Silverlight is used for rendering graphical elements in the Web environment. WCF is used for secure communication between clients and servers.

Management reporting and integration

Q: What native historical data reporting options are available?

Wonderware Historian combines front-end, high-speed data collection with time series extensions to an embedded Microsoft SQL Server relational database to optimise both storage and retrieval performance.

Wonderware Information Server delivers historical and real-time information via charts, trends, data tables and graphical displays.

Rich data analysis is provided with Wonderware Historian Client capabilities, including feature-rich trend charts and X-Y scatter plots.

Integration with:

* Microsoft SharePoint Services.

* Microsoft SQL Server Reporting Services Intelligent Content Linking.

* Wonderware Table Weaver, which provides streamlined content linking and powerful drill-through capabilities.

Q: What product specific interface does the product have iro well-known MES packages?

SAP and generic interfaces using such technologies as OPC, SQL, XML, OLE DB/ADO and proxy objects.

Security and data protection

Q: What authentication, authorisation & role management models are available?

Incorporated in the application and uses the services offered by the OS.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

* Unique Plant Model: Provides a single, consistent definition of infrastructure or plant in meaningful terms and organised as re-usable templates.

* Application objects: Promote and support standards and re-use.

* ArchestrA Workflow software: Enables users to digitise manual and automated processes that include people and/or systems.

* Wonderware System Platform: Eliminates islands of automation through the integration of all devices, systems, databases and software applications within manufacturing and infrastructure environments.

* Flexibility: The ability to easily change applications, control programs and workflow at all levels of the organisation to respond to any business issue or to take advantage of new opportunities.

© Technews Publishing (Pty) Ltd | All Rights Reserved