Gearless motors for elevator drives

August 2010

Motion Control & Drives

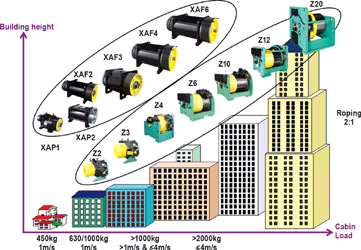

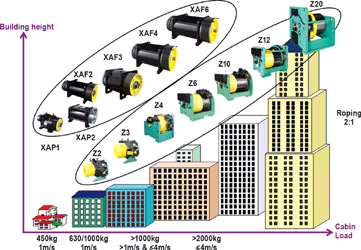

Leroy-Somer’s range of electro-mechanical systems includes gearless drives for new lift installations, as well as for renovation projects that involve the upgrade of existing lifts. “The new XA motors offer high performance solutions in machine roomless lift (MRL) applications and the Z gearless drives are ideal for upgrade and renovation projects,” says Grant Robertson, managing director of Leroy-Somer South Africa. “Leroy-Somer works closely with leading elevator manufacturers during the design phase of a project. The team uses its calculation software and the various lift parameters to propose a solution that complies with all regulatory and safety standards.”

XA series

Gearless motors with internal rotor which are compact and lightweight for easy installation in the lift well. The cigar type design of these motors makes them perfect for use in lift installations with a restricted pit depth. The overhanging traction sheave provides direct access to the grooves and simplifies installation of the cables. The reduced overhead design, due to axial disk brakes, means the motor can be fitted on a beam directly underneath the shaft ceiling. The range covers application requirements up to 2500 kg and a speed of 3 m/s, with a 2:1 roping arrangement. Each motor has a choice of two different sheave diameters in order to prioritise either rated torque or speed. The high efficiency motors have low temperature rise and minimal vibration to give excellent ride performance.

Z series

Gearless motors for new installations or upgrade projects, designed for lifts with a payload of up to 5000 kg and a speed of 5 m/s using a 2:1 roping arrangement. This range, which can handle shaft loads of up to 22 T, has an external rotor and disk brakes on the sheave with manual release levers. This range of permanent magnet synchronous motors is particularly suitable for high capacity lifts, or high-speed applications requiring a double wrap. These motors can also be adapted for the requirements of each installation. Mechanical options for a customised solution include deflection sheaves with chassis, anti-vibration mounts and brake manual release levers. A dedicated electronic card, powered by a 24 VDC battery, can be used for emergency operations.

Motors in the XA and Z range are fitted with failsafe brakes, each with a micro-switch, to comply with global safety codes and offer reduced maintenance requirements.

For more information contact Grant Robertson, Leroy-Somer South Africa, +27 (0)11 455 6212, [email protected], www.leroysomer.co.za

Further reading:

Novel bearing steel next generation of aeroengines

SKF South Africa

Motion Control & Drives

SKF continues to re-imagine intelligent and clean rotation with the development of an innovative temperature-resistant, corrosion-tolerant steel called ARCTIC15 designed for aeroengine bearings.

Read more...

Products from maxon

Motion Control & Drives

A wide range of new products is available from motion control specialist, maxon. with a diverse technology portfolio ranging from highly integrated robotic actuators to powerful servo drives and controllers.

Read more...

Actuators for precise hexapod movements

Motion Control & Drives

Aerotech, manufacturer of high-performance motion control and automation systems, is expanding its Automation1 platform. These compact hexapod devices enable the complete integration of six-axis motion systems into existing control

Read more...

Strategic system upgrades beat mining obsolescence and drive productivity

Motion Control & Drives

Mining operations are under constant pressure to maintain output while controlling costs. One persistent challenge continues to confront the industry, knowing when and how to upgrade aging systems before they become a liability.

Read more...

Precision meets performance: The ELGD Axes Family from Festo

Festo South Africa

Motion Control & Drives

Festo has introduced the ELGD axes family, engineered for the demands of future-focused industries. With cutting-edge guide technology, exceptional rigidity and high load capacity, these axes deliver more performance within the same installation footprint.

Read more...

Condition monitoring in hazardous areas

SKF South Africa

Motion Control & Drives

SKF is further strengthening its condition monitoring offer portfolio by a newly developed hazardous area version of its Microlog Analyzer dBX portable vibration analyser.

Read more...

Rip-and-ship solution speeds up nuclear decommissioning project

Motion Control & Drives

When removing steam generators from decommissioned nuclear reactor buildings, the most economical method is to remove them in one piece. Mammoet was commissioned by Framatome to support with the removal of four steam generators from PreussenElektra’s Nuclear Power Plant Unterweser in Germany.

Read more...

WearCheck turns the focus on friction modifiers

Wearcheck

Motion Control & Drives

One of the most important features of a lubricant is the reduction of friction between two surfaces.A dditives like friction modifiers are added to perform this function. Wearcheck turns the focus on friction modifiers

Read more...

SEW-EURODRIVE transforms drivetrain uptime

SEW-EURODRIVE

Editor's Choice Motion Control & Drives

The DriveRadar IoT Suite from SEW-Eurodrive is an ideal solution for industrial condition monitoring. This powerful ecosystem of intelligent sensors, edge devices and cloud-based analytics ensures that customers have full visibility and control of their operations.

Read more...

PC-based control for flat wire motors for electric vehicles

Beckhoff Automation

Editor's Choice Motion Control & Drives

Special machine manufacturer, ruhlamat Huarui Automation Technologies has unveiled the second generation of its mass production line for flexible stators with bar winding (pins). This enables an extremely short production cycle and line changeover times, supported by PC- and EtherCAT-based control technology from Beckhoff.

Read more...