Adroit and EPM team up to increase the water treatment capacity at Mosselbay.

Adroit is used extensively as a scada solution for many water treatment applications in the Eastern Cape, including Amatola Water, Buffalo City, George, Knysna and Mosselbay municipalities.

After EPM (Electronic & Power Manufacturing), successfully completed the second water treatment works for Knysna municipality in 2007, they were subcontracted by Eigenbau, (who was responsible for the mechanical part of the plant, pipe work, pumps, chemical dosing etc) to manufacture the MCC (motor control centre), electrical control equipment and provide the control solutions for the new treatment works on the Kleinbrak River in Mosselbay. As Adroit’s solutions have been proved in many water treatment applications, there was no doubt that it would be the right choice to meet Mosselbay’s requirements.

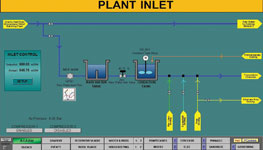

The project was initiated to increase the treatment capacity of the existing works. Unlike the existing plant, the new plant had to be fully automated. The plant controls now consist of the inlet flow control, chemical dosing, filtration and backwash control. A local Adroit Agent Server and Classic User interface was installed at the new works to provide visualisation and diagnostics for the plant. This Agent Server also interfaced to all the existing Adroit Agent Servers in the municipality’s control via a wireless Ethernet back-bone. The local Adroit connected to the plant PLC, an Allen-Bradley Compactlogix, via an OPC server. Adroit’s Modbus Ethernet driver was used to enable communication to all the variable speed drives.

The automated solution was ideal for structured software which would simplify the software implementation and future maintenance. Add-on instructions were created in the PLC for repetitive device control such as variable speed drives, control valves, motor starters and instrumentation. The template mimics in Adroit were used extensively to provide face-plates for these add-on instructions in the PLC.

Adroit’s alarming functionality was used to provide detailed diagnostics and highlight any incorrect plant control. The project was successfully completed and handed over at the end of 2009. During implementation the scope of work was increased to include a sludge pump station, which was built to pump the backwash water collected from the two plants to a farm dam a few kilometres away. This pump station’s electrical equipment was also manufactured by EPM and connected to Adroit via a Spectrum Telemetry system.

Solutions in water and wastewater

Water management is becoming increasingly complex and demands an urgent review to ensure sustainable service delivery and contribution to economic growth to meet present and future needs. Adroit says it is ideally suited to the water and wastewater industries and is trusted by many utilities, mines and municipalities to safely run these valuable and strategic assets.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved