Rockwell’s OEE monitoring solution.

Rockwell Automation Global Solutions division is currently involved in a project which will help to ensure that plant equipment owned by a South African beverage manufacturer operates at optimum efficiency and with significantly enhanced operational life. The beverage manufacturer, a leading producer of fine wines, spirits, ciders and ready-to drink alcoholic beverages, is currently in the roll-out phase following system verification in a successful pilot plant project.

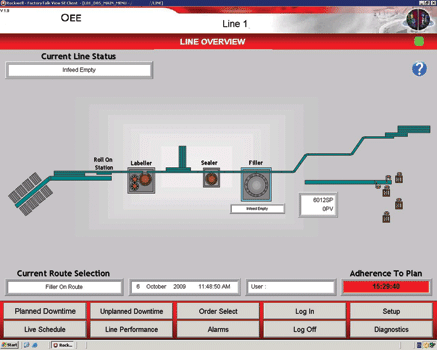

The producer needed to ensure that its current assets were being utilised to their full potential while optimising future capital expenditure through extended working life of the plant’s machinery. To achieve this it needed a system that would give shop floor and management personnel the insight into the workings of the plant that would facilitate implementation of improved production practices. Rockwell installed an overall equipment effectiveness (OEE) monitoring system with FactoryTalk Metrics as its event and calculation engine to achieve this objective.

The system is used for all OEE calculations and downtime monitoring. The event engine is used to monitor deviations from planned production rates and allows operator comments to be linked to the OEE per machine and per a production line. The system is also used to monitor both planned and unplanned downtime of equipment.

Utilising FactoryTalk Site Edition (SE), a human machine interface (HMI) which provides supervisory-level monitoring on a distributed and scalable architecture, the system supports distributed-server and multi-user applications. It also facilitates the visualisation of current production line status by highlighting system backlogs and supply starvation. The HMI independently captures comments on low production and also displays schedule adherence information, which allows operators to capture downtime codes. FactoryTalk SE facilitates total visibility into a plant’s state of production and enables an enterprise wide view offacilities by making production reports available on the company’s intranet.

The challenge on the project was interfacing the OEE and control systems to provide complete decoupling of the two environments. To achieve this, a data concentrator which collects information from the production equipment and sends it to the OEE monitoring system was installed. The information is provided in a newly defined data structure that now forms part of the data standard used for all of the manufacturer’s production equipment. Analysis of the data helps the company effectively control downtime and production performance and to implement best practices for increased production across the plant.

The OEE will now be implemented at nine sites which include a total of 31 production lines. The system is Microsoft Windows based, and has the scalability to provide additional information in the future.

For more information contact Poobie Naidoo, Rockwell Automation, +27 (0)11 654 9700, [email protected], www.rockwellautomation.co.za

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved