Testing of mine shaft ropes

Jan 2000

SCADA/HMI

TLC Software

With the continuous loss of lives in mines more stringent regulations have been implemented to ensure the safety of mine equipment. One of the existing mining regulations requires that ropes used in mineshafts must be tested for minimum breaking strength every six months. Either Lifting Services Mining Services or the CSIR can do the test. Lifting Services Mining Services has commissioned TLC Software to develop a software engineering solution to facilitate its testing process.

These ropes are manufactured according to set standards and each rope is issued with a certificate number and a coil number for identification.

Engineer Pierre Theron at TLC explains how the tensile test program is used during the test: "The end caps of the rope are put into a machine that stretches the rope until it breaks.

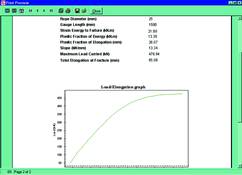

"The tensile test program does realtime plotting of the load/force and elongation of the rope being tested. Realtime plotting is initiated at a predefined load to eliminate rope slack. After break detection, the software stops acquisition.

"The user is then able to select an endpoint on the graph to determine the maximum load carried and the total elongation at fracture. Curve shifting is performed to correct the offset caused by initial rope slack. The strain energy, plastic fraction of energy, plastic fraction of elongation, and slope of the graph in the linear region is then calculated." After a test, a certificate with a unique number is issued for the specific test, and the above results are stored into a database. If a piece of the same rope is tested at a later stage, a new certificate number is issued under the old coil number. Different test results/certificate numbers of the same rope/coil number can then be compared which enables LSMS to determine the life span of a rope and to advise a mine when to replace a rope.

Previously, LSMS performed the test by feeding the load and elongation signals into a specialised photoplotter which had a mechanical arm connected to a pen that drew the graph on paper according to signals received.

TLC Software

(011) 463 3860

Further reading:

HC Series hand controller

SCADA/HMI

The HC Series hand controller is a pre-qualified solution for demanding environments, and ensures safe and intuitive command where standard controls fail.

Read more...

Becoming a leader in alarm annunciators

Omniflex Remote Monitoring Specialists

SCADA/HMI

The rise of the digital age and PC-based systems and graphical interfaces led many to view the traditional annunciator market as obsolete. Omniflex explains how the company saw the market differently to then established players like Highland and Rochester, and how it reshaped the industry.

Read more...

Intuitive CNC HMIs with simulation functionality

Beckhoff Automation

SCADA/HMI

The TwinCAT 3 automation software from Beckhoff offers two new function libraries for CNC-specific user interfaces. These were used to create an advanced, intuitive HMI application specifically for CNC purposes and to simulate part machining using real-time data.

Read more...

HMIs for water treatment facilities

DirectLogic Automation

SCADA/HMI

Having an efficient and well-managed wastewater treatment process is imperative for sustainable water management. However, there are some challenges. To address these, DirectLogic Automation supplies a range of Weintek HMI touch screens featuring state-of-the-art technology, flexibility, rugged construction and open connectivity.

Read more...

Operator panel simplifies control and boosts performance

Siemens South Africa

SCADA/HMI

The Sinamics SDI Pro 14 cm operator panel is an innovative accessory for drive technology, providing efficient support for local engineering.

Read more...

New HMI panel PC series

Vepac Electronics

SCADA/HMI

Industrial computing giant, AAEON has released its OMNI-ADN series, a four-model collection of modular HMI panel PCs, with display sizes ranging from 26 to 55 cm.

Read more...

HMI with maximum performance in the smallest of spaces

ifm - South Africa

SCADA/HMI

Whenever clear communication, precision and performance in the smallest of spaces are required, the most compact member of ifm’s ecomatDisplay family is the perfect choice. The 11 cm HMI makes no compromises when it comes to human-machine interaction.

Read more...

Reduced machine downtime with advanced machine solutions

Omron Electronics

SCADA/HMI

Omron’s advanced machine solutions provide groundbreaking technology that not only minimises downtime but also reduces service costs and ensures uninterrupted operation.

Read more...

Scale your operations control as you need

SCADA/HMI

Modern industrial operations, from a single machine to enterprise-wide systems, demand software which adapts to the task at hand while boosting efficiency,

Read more...

Maximum display performance in the smallest of spaces

ifm - South Africa

SCADA/HMI

Whenever efficient communication, precision and performance in the smallest of spaces are required, the most compact member of the ecomatDisplay family is the perfect choice. This is a programmable, high-performance HMI display designed for mobile machines and installations.

Read more...