Duet Industrial Technology uses Adroit as the preferred solution for the Water Utilities Corporation in Botswana.

Johannesburg-based systems integrator, Duet Industrial Technology, has upgraded the Shashe Dam water treatment works based on the outskirts of Francistown in Botswana.

The Adroit system replaces a legacy supervisory control and data acquisition (scada) for the facility’s new pump station that supplies approximately 1200 m³/hr of treated water to Francistown.

“What impressed us most about the Adroit system is the ease of setting up additional view nodes,” said Robert Mckie, director of Duet Industrial Technology.

“What is more all instrumentation signals are archived for three months and are available for trending. This is particularly important to monitor the water quality.”

As part of the water treatment plant upgrade, numerous parts of the facility were automated, including the filter backwashing systems. The plant was also extended and clarifiers, sand filters, and dosing systems were added. A new pump station was built, with pumps controlled by two new 1250 kW medium voltage variable speed drives (VSDs) and an Adroit SCADA was deployed to monitor and control much of the new instrumentation and equipment.

Duet replaced the existing outdated remote terminal units (RTUs) and existing scada with a state-of-the-art Adroit system and Allen Bradley PLCs. Completed in May 2008 the project is currently in its optimisation phase.

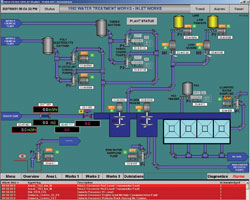

Using Adroit version 6.0.4.1 running on Windows XP, each system has in the region of 2800 tag points. Audible on-screen alarms are used to monitor the process which entails feeding the clarifiers and 14 filters with water from the Shashe Dam, pre-treating the water and after filtering, treating it again to make it safe for human consumption.

The water is then pumped via three pump stations to Francistown, Tonota and the surrounding areas. The Adroit SCADA feeds plant information from the pump site to an existing Adroit installation at the treatment facility some 30 km away using an Ethernet wireless network.

The Adroit stations offer the operators valuable information regarding the status of all the plant equipment. In addition the detailed pop-up screens and alarming system makes it easy for the technical staff to troubleshoot problems in the field.

There are two main operator nodes (scada workstations), centrally located in the main control room, the two nodes are both permanently connected to the control network to give redundancy in the scada stations. Each server has full access to the complete control network and connects to a control system on an Ethernet network. Two remote viewing stations allow technical and managerial staff to access the full system.

A total of 17 Allen Bradley Compact Logix PLCs and Allen Bradley Flex I/O stations are linked on an Ethernet network, with radios being used to span across the 40 odd km range. Duet used standard Adroit graphics for the installations with some symbols self generated where they did not exist.

For more information contact Monica Mynhardt, Adroit Technologies, +27 (0)11 658 8100, [email protected], www.adroit.co.za

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved