LEU Anlagenbau of Ueten-dorf, a Swiss manufacturer of specialist machines for the automatic selection, rotation and washing of cheeses has standardised on AC drives from Control Techniques.

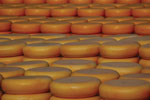

The annual cheese production of Switzerland is in the region of 170 000 tonnes from approximately 1200 dairies. Much of this production is in the form of large blocks or ‘wheels’ of cheese up to 1 metre in diameter, weight ranges from just a few kg up to 50 kg or more. As part of the process of maturation, cheeses are stored in temperature-controlled ageing cheese cellars from two months to three years depending on their variety, until fully ripened. When the cheeses are young, they must be turned daily and washed with brine – a process that controls the surface bacteria and contributes to the character and taste of the cheese. This is a heavy, labour-intensive chore that must be carried out millions of times a day across cheese storage facilities.

Each machine is designed to move along aisles of racking from left or right and to select, in turn, trays with single or multiple cheeses on. The cheeses are taken into the machine body, rotated and then scrubbed with brine using rotating brushes. The cheese or cheeses are returned to their tray, (whilst the next selection is already moving into the washing section) and back to their designated position in the racking.

Each of these actions is a servo axis controlled by a Control Techniques drive. The Unidrive SP is responsible for the positioning of the driven rack into the collection/return position, the delivery position into the machine and the retrieval position after washing. The 4 or 7,5 kW drive (size depending on the size and weight of the cheeses) receives its position signal from a controller, which receives feedback from an absolute controller. Repeatable positional accuracy has proved to be ±0,1 mm. “In the next generation of machines, we plan to use the applications module within the Unidrive SP as the position controller,” says Thomas Kilchemann, “with feedback from a Sin/Cos encoder.”

There can be up to 11 further axes, depending on the machines, each of which is under the control of a 0,55 or 1,5 kW Commander SK AC drive. Each receives its speed/position set point from the main controlling CPU. These axes include: pusher (to push the cheese from the board to machine); cheese turner; brush rotation; rotary vertical and lateral movement of the rotary plate; pusher (to extract the cheese); gripper; lateral movement of board; support of board and board centring.

The operator simply moves the machine to its start point, programs in the sequence of cheese selection and, from then on, the operation is completely automatic.

LEU cheese handling machines have the capacity to handle up to 180 boards (540 cheeses) per hour, 23 hours a day for seven days a week – a huge increase on the human equivalent. The machines have to operate in a corrosive environment, with constant salt spray and the presence of ammonia. They are built to wash-down standards, with IP55 protected cubicles and AC motors with sealed bearings and special protective coatings.

“We have considerable confidence in Control Techniques,” concludes managing director, Beat Blätter. “We have received excellent support from the Zurich Drive Centre and their drives have potential that we have not yet fully exploited. We have moved 100% to Control Techniques drives due to their reliability and compact size.”

For more information contact Bill Tedd, Control Techniques, +27 (0)11 462 1740, [email protected], www.controltechniques.com

| Tel: | +27 11 462 1740 |

| Fax: | +27 11 462 1941 |

| Email: | [email protected] |

| www: | www.nidecautomation.com |

| Articles: | More information and articles about Nidec Industrial Automation Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved