South African supervisory control and data acquisition (scada) developers, Adroit Technologies, and integration partner, Sofotek, joined forces in December 2007 to tackle the MyTank project in Maseru, Lesotho.

The site is situated in the heart of Maseru and functions as a distribution station for diesel, IP paraffin and petrol in the area. The MyTank system is comprised of three primary subsystems, namely: flow metering; tank gauging and tank calibration. Opus version 4.0 was implemented together with the Adroit Scada to provide a scalable and reliable solution ensuring optimal productivity of the 1,3 million litre 15 tank depot.

The Technical Services division of Adroit Technologies under the supervision of Sofotek, provided the capabilities to gather realtime information and provide realtime data and reports on a daily and monthly basis, evaluating the stock movement and holding of the 15 tanks in the depot. Previously management would rely on monthly reports manually compiled by operators who would take a physical dip of the level of the tank before and after a truck loads or offloads. These dip values were then compared to dip tables and written down.

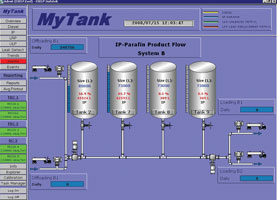

With the MyTank system, these reports are derived from the Adroit SCADA, where they are displayed in mimics. Calculations are made through sets of expressions, scripts and statistical agents and realtime results are calculated and displayed in Opus. The management teams, both on- and off-site are now able to view the OPUS-generated reports in realtime ensuring substantial business improvement and performance management. Opus reports are automatically sent daily to a list of management members.

The front end of the solution is comprised of level sensors to provide continuous realtime level readings, coupled with flowmeters to accurately establish the volume of product entering or leaving the tanks. Flowmeters with air eliminators were chosen for extra accuracy. The data is sent from the field instruments to MOXA PLCs through wireless D-Link units (4-20 mA), which provide a secure 802.11 Wi-Fi network.

Databasing consists mainly of MS-SQL and MS-Access. A calibration strategy had to be developed for tank monitoring to cater for the variances that have been introduced by the site-specific conditions. (ie, tanks lying at an angle due to earth movements) which prohibits the use of the 'as-built' dip tables to determine the realtime volume. This runs mainly through scripting and data basing and has an accuracy of 100 litres on an 83 000 litre tank.

For more information contact Andrew Evangelidis, Sofotek, +27 (0)11 706 1134, [email protected] or Monica Mynhardt, Adroit Technologies, +27 (0)11 658 8100, [email protected], www.adroit.co.za

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved