Global competition and the drive for improved operational efficiency have sparked demand for realtime supervisory control and data acquisition (scada) systems that offer Advanced Alarm Management technology. Adroit's scada/HMI (human machine interface) boasts the latest in market driven Advanced Alarm Management technology in its recently released version 7.0.

Over 90% of all scada installations have some alarming configuration. Mike Lamusse, technical director of Adroit Technologies, "We identified that there is enormous value in a good and well constructed alarm strategy. Along with historical data in the form of trends, the alarms and events generated in any process are the live indicators that operators use to run and optimise the process. Adroit has always had the capability to enable users to log events and alarms into a database but historically, this required that they develop the queries and reporting to support the analysis and business intelligence aspects."

Adroit's version 7.0 with Advanced Alarm Management Agent plugs directly into the Agent Server on top of the existing alarm configurations and enables users, through simple configuration, to construct an Advanced Alarming capability.

According to the EEMUA 191 guidelines, an alarm is an event to which an operator must react, respond and acknowledge (not simply acknowledge and ignore) and no plant should have more than six such alarm occurrences per hour.

In recent times operators have found that there are simply too many alarms. On one large diamond mine it was necessary for Adroit to configure over 10 000 alarms to monitor various functions.

The Alarm Management Agent analyses, manages and monitors alarm systems giving users statistical data of existing alarming configurations that can be used to remove nuisance alarms, adjust noisy alarm limits, and identify problematic process areas and equipment.

Dave Wibberley, managing director of Adroit Technologies says, "Systems, plants and processes are run by human beings. They are often under pressure working the third shift, late into the night and often short on motivation. It is these operators who need to ensure that the process runs optimally. Adroit assists the process by focusing their attention into the areas that will make their lives easier by identifying problem areas and, secondly, give them information that motivates their actions by showing their performance against targets."

"Given that most sites suffer from too much alarm noise, the only way to resolve the problem is through a well planned and executed alarm strategy using smart technology such as the Adroit Advanced Alarm Agent."

Use of the system improves process efficiencies by addressing potential and existing problem areas. By eliminating alarms that are inconsequential the system helps monitor operations and operator workload. The information is used to identify process bottlenecks and impact on operator workload and efficiencies. It also reduces the problem of mass acknowledgement where alarms are sometimes acknowledged blindly.

The Advanced Alarm Agent collects alarms and events across the entire enterprise, thereby centralising problem solving via a central database. It also eliminates nuisance alarms via conditional alarming and post analysis repair.

Lamusse says, "Now that we have all the data in an open central database the sky is the limit. The future will lie in user's abilities to construct their own views." Incidents are stored to a database of the user's choice. Adroit recommends that the database be remotely accessible by third party Manufacturing Information System (MIS) applications for optimal mobility and efficiency.

Historically alarming provided too much data, not enough information, and data that was not of interest. Adroit's system replaces alarm printers, providing only what is key to the monitoring and control of the business process.

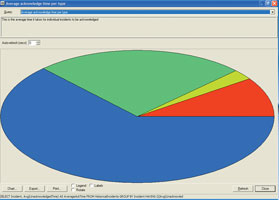

By recording various alarm time parameters, application of reasons and custom notes the system also enables fast and thorough incident reviews. As part of the solution the user has easy access to about 15 different views and analysis of the data in both tabular and graphical format.

"The first step is to get a reliable, well designed relational database going. This should contain everything surrounding the event or alarm. It is not good enough to simply use the raw data, you also need context," says Wibberley.

There has been much academic and industry body work done on the subject of alarms, and there are third party software applications making their way into the industrial arena but they are often too complicated and expensive. This is because they tend to focus on the events and alarms themselves without taking into account the dynamics of the process. For example: the time it takes some operators to simply acknowledge, clear and reset the alarm.

Adhering to Adroit's strategic philosophy, the new technology has been integrated as part of the Adroit scada software, making deployment and configuration simple.

Incidents can be categorised, making queries relation to processes, physical areas or equipment easy. Incident records include time, clearing and acknowledgement for operator accountability.

Incidents can be enabled for alarm reasoning, using pre-configured reasons and sub-reasons, plus optional free format comments.

"In future roadmaps, we will be working on delivering even higher value knowledge such as parent/child relationships, pointing users in the direction of which alarms are inhibiting production, or even better to find patterns in alarms that will be meaningful to creating a smoother more efficient running operation," concludes Lamusse.

For more information contact Dave Wibberley, Adroit Technologies, +27 (0)11 658 8100, [email protected], www.adroit.co.za

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved