Pressure is an important factor in the processing of gold. When the medium to be measured is abrasive, measuring instruments can wear out extremely quickly and require frequent replacement. This translates into high costs.

In large gold mines, such as those in South Africa and Australia, gold-bearing ore is recovered using machines. For the extraction of gold, water is added to the mined ore. This mixture is then pumped from the mine to the gold mill and extraction plant. The pressure measuring instruments used to monitor the feed pumps must resist the abrasive effects of the slurry.

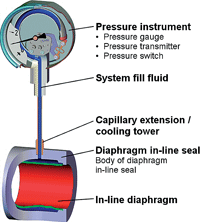

One possibility in protecting the pressure gauge or pressure transmitter from sand, solid dirt particles and blunt objects is an assembly with a diaphragm seal. If standard pressure gauges were used, the process medium would clog their entry bore and harden. However, with a diaphragm seal, a metal diaphragm separates the measuring instrument from the process media. Figure 1 shows an in-line diaphragm seal assembly with capillary.

Operating principle of a diaphragm seal system

The inner cavity between the diaphragm and the pressure measuring instrument is completely filled with a system fill fluid. The process pressure is transmitted by the elastic diaphragm into the transmitting fluid and from there to the measuring element, ie to a pressure gauge or transmitter. In this way, pressure can be reliably measured. But even a stainless steel diaphragm can wear out over time when constantly subjected to the abrasive media.

Wika has developed two special diaphragm seals which are well-suited to use with abrasive mining slurries.

In-line polyurethane diaphragm seal

The in-line diaphragm seal with polyurethane diaphragm (see Figure 2) is robust and has proven to be successful in the gold mining industry. This flanged seal is installed directly between two flanges and becomes an integral part of the pipeline. It replaces the conventional 'T-piece' in the process piping system. The polyurethane diaphragm provides excellent protection from deposits in the process.

The cylindrical diaphragm minimises protrusions or interruptions to the process flow. This elastomer diaphragm is bolted to the seal body. Optionally, Halar-coated (ECTFE) outer flanges are available for additional wear resistance. A variety of nominal pipe diameters enables adaptation to the cross-section of the particular pipeline.

Diaphragm seal with protection disc

An alternative to the in-line diaphragm seal is a diaphragm seal with protective disc. The gold mixture would act like sandpaper to a normal diaphragm; the diaphragm would be rubbed away over time. The protection disc separates the diaphragm of the measuring instrument from the abrasive sludge mixture. The design is insensitive to blows and impacts on the protection disc, which has sufficient thickness to resist the abrasion from the process media.

This type of diaphragm seal (see Figure 3), which can be combined with a pressure gauge, an electronic pressure transmitter or pressure switch, has been proven for use for mining and waste removal as well as use in cast plaster pumps and concrete pumps.

Conclusion

While gold mining can present severe conditions, special designs and materials can provide protection for the pressure measuring instruments. The configuration of the combination of pressure measuring instruments and diaphragm seals depends, among other things, on the application conditions in which the assembly must work. WIKA can help users to select suitable diaphragm seals and the best configuration for their application. In this way downtime is reduced and substantial savings regarding maintenance and repair are realised.

| Tel: | +27 11 621 0000 |

| Email: | [email protected] |

| www: | www.wika.co.za |

| Articles: | More information and articles about WIKA Instruments |

© Technews Publishing (Pty) Ltd | All Rights Reserved