In manufacturing, being able to intimately manage every aspect of the production line provides significant benefits in overall productivity, quality and most importantly security. If just one part of the operation is functioning below capacity, it can negatively impact output and affect the bottom line. With increasing emphasis being placed on labour, cost and process optimisation, an effective factory management system becomes crucial in maintaining a successful enterprise.

Rockwell Automation, a leading international supplier of process automation and information solutions, offers FactoryTalk AssetCentre, a modular asset management solution that enables intelligent single point control and monitoring of the entire factory floor. Using this application, manufacturers can secure access to control systems, track process changes via comprehensive audit trails, manage asset configuration files (version control) and, through system backup, assist with disaster recovery.

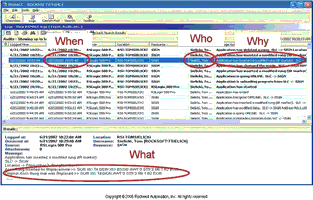

Deon Engelbrecht, business manager: Rockwell Software Africa & Middle East Region, says: "The security and management advantages of this asset management system are substantial. Users can be allocated individual access rights to assets, their files and programming tools based on their expertise. The system records what process or system changes were made, when, why and by whom. If the result of the change is unsatisfactory, it is simple to revert to the previous versions of the operation."

The system manages program versions and automatically backs them up in a central database. In the event of a disaster or malfunction, this enables fast and cost effective recovery.

Engelbrecht continues: "This level of traceability is extremely valuable, it facilitates instant error correction, process refinement for optimal production output and complete accountability. This in turn reduces variability in productivity and quality, improves the efficiency of indirect labour and lowers commissioning time and cost - an attractive list of benefits for any manufacturer."

Through its security and management functions, FactoryTalk AssetCentre assists manufacturing compliance in the regulated industries, such as in the pharmaceutical industry, and in other industries that are governed by regulations such as 21 CFR Part 11, HACCP, HIRARC, EHS, ISO9001-2000 and require unwavering product quality throughout the asset lifecycle.

The software also addresses safety. A comprehensive audit trail means that processes can be validated by the right person and in accordance with ruling safety legislation. Used in this way, it helps decrease the risk of injuries to employees, contractors and to anyone else on the factory floor.

Rockwell Automation's acquisition of automation software specialists GEPA has given the company access to powerful and cross compatible software technology, which has been incorporated into FactoryTalk AssetCentre. This gives the system a dynamic edge, making it adaptable across various applications on control systems from other vendors including Siemens and Schneider.

For more information contact Deon Engelbrecht, +27 (0)11 654 9700, [email protected], www.rockwellautomation.co.za

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved