At an investment of about US$ 2 billion, primary aluminium smelter BHP Billiton's MOZAL (MOZambique ALuminium) industrial project is the largest ever undertaken in Mozambique. The smelting of alumina is done on a 24/7 basis using locally produced anodes and about 950 MW of electricity to produce over 500 000 tons of primary aluminium per annum. This places the rapid diagnosis of the exact causes of power failures very near the top of the production agenda.

In order to track the source of power failures, the smelter has adopted a time stamping approach at its MOZAL substation. This has also proved invaluable for maintenance plans and actions. The objective of this approach is to minimise downtime through the analysis of accurately time-stamped events. Custom queries can be done to audit any recurring problems in order to reduce or prevent failures in the future. Projects can also be developed to improve or eliminate abnormal operations.

"We had been working with Wonderware scada products for about seven years and found them reliable. So we looked for a Wonderware solution that would best address our current needs and decided on ArchestrA," says MOZAL SARL automation specialist Daniel Madumelane. "We upgraded our InTouch HMI (human-machine interface) and ActiveFactory reporting software to work under the ArchestrA umbrella."

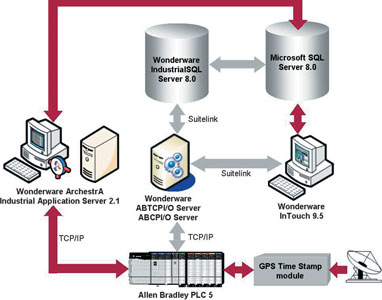

The substation monitoring system comprises 22 Allen-Bradley PLCs with up to four GPS time-stamping cards per PLC. If any event occurs, the PLC sets a flag that new data is available. The ArchestrA Automation Object Server (AOS) keeps checking for this flag in order to download the data and forward it to the SQL database.

ArchestrA provided for the creation of a generic master card template, which covered all the common issues across all PLCs and from which five other templates were derived to address individual differences per PLC such as the number of time-stamping cards, the tag name list and their interface addresses.

Redundancy is done at the PLC level, which means that in the case of a communication break with ArchestrA, the time-stamping cards keep logging events until the buffer is full. Because of the slow event rate, filling the buffer can take some time, thereby providing sufficient opportunity to locate and fix communication problems, after which the downloading process restarts automatically. This goes a long way to guaranteeing that data will not be lost.

The implementation included a mixture of challenges and surprising successes. "Since ArchestrA replaced the previous system based on InControl, we really had to understand how the previous system functioned so that the new system would provide the same functionality," says Selvan Govender, automation specialist, MOZAL SARL. "Another challenge was learning how to apply standards for the existing structure and how to address the differences between the various PLC configurations. This was also our first in-house project done using ArchestrA. In spite of all this we completed the project within one month. We could have taken less time but we also had to handle our usual work load at the same time."

Some of the realised benefits of the new system include reduced plant downtime, less resources needed for fault-finding, improved confidence in fault diagnosis, greater system uptime and ease of use.

For more information contact Justin Tweedie, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved