Power supplies with a DC input voltage of 360-900 V can be directly connected to the intermediate DC-bus of a frequency drive. The advantages are interesting but special precautions are required when connecting the power supply.

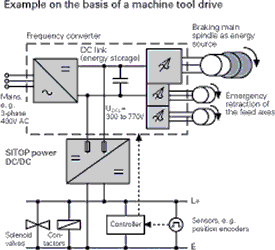

Power supplies for control systems are traditionally connected to either a 1-phase or 3-phase AC mains supply. However, due to the increasing use of frequency drives and amplifiers, there is a new option of connecting the power supplies to the intermediate DC-bus of a frequency drive (Figure 1). One of the greatest advantages is that you can use the kinetic energy of the motors as a way of supplying the control system. This intriguing configuration significantly increases the stability against AC mains fluctuations without needing to employ battery back-up and its associated costly maintenance.

A good example is the use of a crane application. What happens when a crane has just hoisted its load up into the air and the AC power fails?

Normally, the control system would have to be battery backed-up so that power is available when lowering the load back to the ground. However, if the control system is supplied through the intermediate DC-bus, the crane's motor can act as a generator when the load is lowered. The energy from the motor keeps the intermediate DC-bus voltage live which in turn keeps the power supply energised allowing for DC power for the control system simplifying and increasing the reliability of the design.

The PULS QTD20.241 can benefit users by eliminating the costly breakage of tools and material due to AC mains failures and fluctuations. Some examples are textile, paper and grinding machines as well as crane applications previously mentioned.

The device can keep the control system energised long enough to provide a controlled and safe shut-down of equipment during power loss making it the perfect choice as an addition to your drive system.

What special requirements does a power supply that is suitable for the intermediate DC-bus need?

One might think there are no special requirements needed because, from the basic design principle, switching power supplies can be operated with both AC and DC. Sometimes power supplies are also specified with a DC voltage range of 450-750 V, so why do problems arise in practical use when they are connected to the intermediate DC-bus?

Firstly, the voltage of an intermediate DC-bus is often a high-frequency AC voltage with several hundred volts of amplitude and switching voltage edges against ground. True 'DC voltage' applies only to the voltage between the positive and negative terminals but is not referenced to ground. However, the intermediate DC-bus jumps back and forth in common mode referenced to ground.

Secondly, the interference on an intermediate DC-bus exceeds the permissible values for a power line by many factors of 10 and therefore the requirements for a power supply connected to an intermediate DC-bus are quite different than for a typical power supply.

The PULS QTD20.241 offers an application-specific power supply with a continuous output of 24 V and 20 A. One important difference from standard PULS power supplies is that the direction of the EMI filter has been turned around. Normally, the filters are arranged so that the interference generated in the power supply does not feed back to the power lines which must be kept clean. However, in an intermediate DC-bus connection the filters should block the interference generated from this connection.

© Technews Publishing (Pty) Ltd | All Rights Reserved