Working together, global leaders Rockwell Automation, Endress+Hauser and Spectrum Controls have combined their core competencies to provide a wide range of pre-integrated, pre-tested, measurement, automation and information solutions based on global standards.

As part of a complete process asset management solution, FieldCare software can provide users with multiple benefits, including significant initial and annual savings, better decision-making and interpretation, rapid troubleshooting, recognition of performance deterioration, remote diagnostics and reconfiguration, efficient planning of scheduled shutdowns and easy access to instrument information.

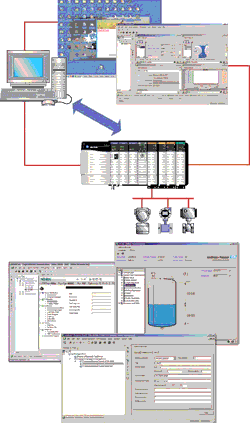

The FieldCare HART Configuration Bundle incorporates all the software that plant and maintenance engineers need for effective asset management of HART field devices connected to ControlLogix or CompactLogix programmable automation controllers and Flex I/O from Rockwell Automation.

The bundle comprises Endress+Hauser FieldCare Plant Asset Management Software, Spectrum Controls Connects software, Rockwell Automation RSLinx Professional Software and a one-year TechConnect support contract. It also includes the communication Device Type Management (DTM) programs and drivers needed to configure and manage HART instruments attached to the Rockwell Automation Integrated Architecture system. Industries where this bundle will be of particular interest include food and beverage, life sciences, chemical, oil and gas, water/wastewater, pulp and paper, power generation and mining.

Because FieldCare is based on the open Field Device Tool/Device Type Manager (FDT/DTM) standard, this bundle will allow users to configure and manage any HART device with a DTM. DTMs for all Endress+Hauser instruments are also included. The bundle can be simply loaded onto a PC that resides on the Ethernet/IP or ControlNet network and you are ready to go. Users can configure, calibrate, tune, analyse and optimise HART devices connected to Spectrum Controls HART analog I/O modules installed within ControlLogix and/or CompactLogix and/or Flex I/O and FlexEX-based process automation system.

HART-capable field instruments provide the diagnostic and process control information that users require to optimise their production assets. When connected to ControlLogix, CompactLogix, Flex I/O and FlexEX I/O modules with built-in HART communication, there is no need for extra hardware or wiring to access the HART data for use as part of a standard maintenance program.

Leveraging the power of the Rockwell Automation Integrated Architecture, HART I/O modules pass data to a ControlLogix or CompactLogix controller over the backplane, while at the same time, using RSLinx, Connects software translates CIP messages that encapsulate the HART data to be used by FieldCare asset management software. Users can also use Allen-Bradley FLEX and FLEX EX HART analog I/O modules as an alternative or complementary I/O solution for applications in which the digital HART signal is used for asset management purposes only and the analog signal is used exclusively for control. As well as all HART data, the instrument also uses a conventional 4-20 mA signal for the process variable complementing regular analog and digital I/O signals.

For more information contact Vusi Sithole, Rockwell Automation, +27 (0)11 654 9700, [email protected], www.rockwellautomation.co.za

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved