Process variations cost money and their root cause is often difficult to determine. CSense is a unique software product that enables managers and production personnel to do rapid process troubleshooting in order to understand and reduce process variations. From October 2006, CSense will be able to export objects, or combinations of objects, that represent on-line solutions, to Wonderware's ArchestrA.

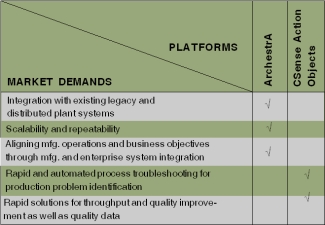

The benefit of this for end-users is that CSense can be used as a development environment to create rapid process troubleshooting solutions, while embedding these 'Action Objects' in today's leading industrial automation and MES software architecture. The merging of rapid process troubleshooting capabilities with ArchestrA's agile control and information infrastructure leads to a new level of production and performance management and optimisation.

'Rapid process troubleshooting' refers to the methodology and technology implemented by CSense to troubleshoot production problems rapidly and easily, and to deploy solutions for throughput, quality, energy and data quality improvement. In today's competitive and cost-conscious markets, rapid production problem diagnosis and cure is not a luxury.

Ten years ago, a product's selling price was based on its manufacturing cost plus a profit margin. Today, competition pegs the selling price and the only option left for maintaining the profit margin is to lower the product's manufacturing cost. An important component of that cost is whether the manufacturing process runs smoothly or not.

So, why is CSense necessary?

* Process variation such as deviation from targeted throughput and product quality is expensive.

* Process variation can also be hard to explain. Most processes are complex and dynamic, and to relate relevant process variables to process performance is not simple.

* Furthermore, variation can be difficult to reduce, whether by understanding how to modify the operational philosophy, diagnostic solutions or advanced control.

* Reduction in process variance leads to large monetary savings.

* Historian data in general is poorly utilised, compared to the value that can be extracted with model-based troubleshooting techniques.

* With CSense the causes for process variation is identified, while also offering realtime solutions to reduce this variation.

Figure 2 shows the new CSense Wizard environment in which new knowledge is discovered from data with powerful yet user-friendly tools. The newly-extracted knowledge is combined with existing knowledge. One such example might be operational best practices that can be expressed as fuzzy rules. This 'Action Object' (a solution to the problem) is built in the same environment and its benefit estimated before being exported directly to ArchestrA. To develop a more comprehensive solution with multiple components and layers, CSense Architect is used and provides a visual drag-and-drop environment from libraries for rapid solution development. This complete solution can be compiled and exported as an object to ArchestrA.

"Production and performance management is at the core of the wealth-creating potential of any manufacturing or mining company and the seamless integration of CSense Action Objects with ArchestrA allows for important improvements in this area," says Justin Tweedie, MD of Futuristix, sole SA distributor for the Wonderware range. "This integration also highlights one of ArchestrA's primary design objectives which was the ability to host applications from a diversity of solution vendors to the benefit of end-users."

With more than 20 000 installations worldwide since its introduction in 1997, Wonderware's IndustrialSQL Server is the industry's most popular plant data historian. It integrates information from a wide variety of plant automation and IT information sources to provide plant personnel with a complete data record of plant operations used to assist in today's performance management initiatives.

"Wherever it is used, Wonderware's IndustrialSQL Server realtime historian is full of important process information which CSense can use for diagnostic and troubleshooting purposes," says Derick Moolman of CSense Systems. "This has led to some significant and profitable process improvements in the past and we feel that integration with the ArchestrA platform will greatly facilitate this trend in the future."

For more information contact Derick Moolman or Pierre Human, CSense Systems, +27 (0) 12 347 3110, [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved