From cosmetics to conveyors, beverages to paint, accuracy of the weight of the final product is crucial to the production process. Linda Eales, Schneider Electric South Africa's automation product manager says: "The integrated weighing function in Schneider's Premium PLCs has always been a strong differentiating key factor against competition. The Premium weighing module can be used for the spectrum of process weighing applications such as blending, batching, filling, discontinuous and continuous totalising, check weighing, weigh bridge, level by weight, counting by weight and weight rate monitoring".

The Premium TSXISPY 101 performs 50 measurements per second and manages two reflex outputs. It also fits legally for trade applications that are requiring a class III (6,000d) or class IIII (1,000d) accuracy according to OIML standards.

Any world-wide marketed load cells based on strain gauge technology (Wheatstone bridge principle) can be connected to the Premium module, no matter what their design topology is (single point, bending beam, shear beam, compression, tension/compression or bending ring) and whatever their nominal capacity is but respecting admissible excitation (supply voltage) of 10 V d.c., an output resistance no lower than 43 Ω and no greater than 1 kΩ, rated output from 1 mV/V to 4 mV/V and delivery via a four-wire or six-wire cable.

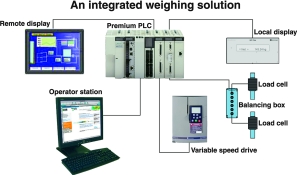

Load cells are connected to the weighing module, where there is more than one load cell (each having the same nominal capacity, rated output and internal resistance), using a summing box. Load cells must be connected parallel to one another.

A dedicated measurement cable is required from the summing box to the module. In the case where more than four load cells are needed to design the scale, for example, where there is a weighbridge or a long conveyor, and depending on the shape of the frame, three or more summing boxes are required.

When the application requires a local display in the event, for example, where it is located less than 100 metres from the weighing module, Schneider's TSXXBTH 100 display unit can be directly connected to the weighing module according to a reliable, dedicated weighing protocol. No program is required - just connection to the module with the proper cable. Current weight values and any other valuable information are instantly available. If required, as many as four display units can be connected on the same module.

Migration of a PL7 weighing configuration to Unity has two alternative factors to consider. If the PL7 application is based only on TSXISPY101 modules, there are no migration problems. In the event that the PL7 application is based on TSXISPY100 modules that are not managed by P-Unity: this legacy module has to be replaced by a new TSXISPY101 module, which is available at preferential pricing. A new module would require that the scale be recalibrated.

The TSXISPY101 module has held CE test certificate # LNE n°01-08 since 27 September 2001. It has also held CE type approval certificate n° 97.00.620.016.0, rev. 99.00.620.051.0, for non-automatic instrument application, such as a weighbridge, since 2 November 1999. Two further CE type approval certificates issued by French body SDM to address the following automatic weighing instrument (AWI) applications are available: continuous totalising automatic weighing instrument (when using SP7SA85 software): certificate #02.00.697.004.1, 3 May 2002 according R50 OIML recommendation and discontinuous totalising automatic weighing instrument (when using SP7SA40 software): certificate #02.00.697.003.1, 3 May 2002 according R107 OIML recommendation.

According to the new ATEX (ATmosphere EXplosible) European directive, an EC certificate of conformity is now available for a Premium weighing system connected to load cells placed in zone 1 or 2 (gas) and 21 or 22 (dust).

For more information contact Linda Eales, Schneider Electric, 011 254 6400.

| Tel: | +27 11 254 6400 |

| Email: | [email protected] |

| www: | www.se.com/za/en/ |

| Articles: | More information and articles about Schneider Electric South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved