With South Africa fast becoming part of the global village through continuous globalisation, many of the country's top manufacturing concerns have suddenly come under considerable competitive pressure from various sources around the world. China, Korea, Japan and India are pressuring local industries to manufacture more cost effectively to maintain their competitive edge. Manufacturers have to reduce waste and improve production without investing in new machinery, they have to get the most out of the assets they already have. It is thus not surprising to find that, like similar companies in Europe and the US, almost all of these concerns have some form of business performance improvement initiative.

Industry analysts ARC Advisory Group reported that in 2005 the business performance improvement initiative of choice was 'lean manufacturing' with over 60% of manufacturers in North America and Europe using lean manufacturing as their primary improvement methodology, followed by overall equipment effectiveness (OEE), six sigma, total quality management (TQM) and total production management (TPM).

Industry analysts ARC Advisory Group also reported that over a third (37%) of manufacturers in North America and Europe that used 'lean manufacturing' as a business performance improvement initiative stated that their programme implementation was less than significant. Only 3,5% of companies have completed their implementations with half (50%) of them stating that their companies achieved a 10% or less improvement. The other 25% of companies reported that the savings, if any, could not even be measured. Only 25% of companies that completed their lean implementations achieved a business improvement of more than 10%.

Professor J.J. Pieterse, a lean manufacturing expert from the Business School at the Nelson Mandela Metropolitan University, estimates that in South Africa the success rate of lean implementations in manufacturing is around the 10% mark, with the motor industry being responsible for most of the success stories.

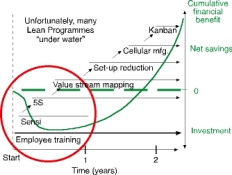

The graph (Figure 1) shows a typical lean manufacturing implementation in North America and Europe showing very significantly a timeline and a graph that highlights the company investment and then the first savings and financial benefit after approximately 20 months. Clearly there is a long lead time before financial results are achieved, leading to problems with commitment. Most programmes get stuck because of the lack of ability to get timely information, the lack of understandable progress reporting to management and the cost of implementation becomes too high.

Professor Pieterse states that some of the further challenges that South African manufacturers face when attempting to implement Lean are:

* Long supply lines.

* Unsophisticated suppliers (quality practices and delivery discipline).

* Elementary and unreliable transport infrastructure.

* Crime.

* Extensive and often militant unionisation.

* Lack of training.

Many of the techniques used in lean manufacturing and OEE are information-based or information reliant systems. Unfortunately the technology used to support these systems in the past has been deliberately low-tech. Computer supplied information was not timely and accessible, software was not flexible enough to capture changes on the shop floor, operator interfaces were complicated and intimidating, and the general view was that the technology obscured reality rather than amplifying the view.

In a recent report by McKinsey & Company on lean and IT, it is reported that companies that use a combination of continuous performance improvement initiatives (CI) and IT are performing much better than companies that have only used one approach. While manual processes achieve good results, adding automation and realtime data achieves better results.

The information requirements of systems that support current business performance improvement initiative are that the information needs to be available at the actual workplace ie, realtime information about a specific production line and its various stages needs to be available to the operator of that line. This plant floor data must also be available to the CEO should he require it. The information must be configurable, in visual displays, correct and unambiguous.

True modern day MES systems like Ampla, by Citect, have been developed to assist manufacturers in the implementation and management of their business performance improvement initiatives. These MES systems allow the user to improve the production efficiency, performance and profitability of manufacturers by processing, analysing and presenting important realtime intelligence from across the business. This allows corporate, IT, plant and production managers to make faster and better decisions based on accurate and current information.

Only if the information provided by these systems is used as a driver of actions, according to the stipulations of the various business performance improvement initiatives, will the implementation be accelerated and the benefits derived from embarking on a business performance improvement initiative be achieved in an acceptable timeframe.

For more information contact Deon Engelbrecht, Citect Africa, 011 699 6600, www.prei.co.za, or visit www.citect.com

© Technews Publishing (Pty) Ltd | All Rights Reserved