With recent emphasis on demand side management, cost smart companies are seizing the opportunity to create value via the measurement and monitoring of energy consumption. Pairing an Adroit supervisory control and data acquisition (scada) system and a PowerSmart energy management package from automation consultants, NC Automation Engineering, is proving to be an effective solution for plants that want to take advantage of Eskom's energy incentives plans.

While most meter manufacturers offer software which is able to retrieve data from their meters, these packages typically do not provide for the easy integration of the data into production monitoring and control systems or billing reporting systems leading to the creation of 'islands of information' rather than a comprehensive solution.

"Energy data that is cleverly combined with production data in the Adroit system allows for the possibilities of truly understanding how a company's daily operation can be made more energy and cost efficient. Without measurement and analysis there is no control. Once this step is accomplished a strategy can be developed to act on this information either automatically or via human interaction to reduce costs," says Jason Wright, director of NC Automation.

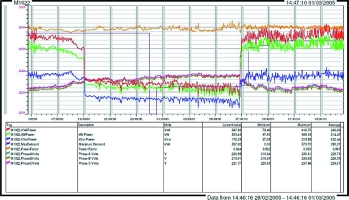

Advantages of an Adroit/PowerSmart combination include energy readings and consumption data that is displayed on the scada with trending and alarm facilities. This information can be viewed on screen in conjunction with realtime shop floor and production data for a comprehensive picture of the plants productivity versus costs.

For example, NC Automation recently installed this system combination at a major supermarket chain, where energy consumption was dramatically affected by the shops lighting systems. SMS alarming alerted the store manager if lights were not turned off at a certain time, thereby ensuring that energy was not lost to human error. By taking the system one step further, this nationwide chain could use the energy trends from the Adroit system to benchmark each store by size, giving other store owners of similar size outlets a sound estimation of what their energy costs should be.

Wright says: "Adroit's custom agent and template mimics and trends allowed us to create an energy meter agent/object with all the built in alarming, functionality and requisite tags available from the energy meter making configuration of large scale energy management systems involving lots of meters quick and easy." Using the Adroit/PowerSmart package, a plant load profile data can be applied against the supplier tariff structure to detect inefficiencies and then to develop strategies to optimise energy consumption using alternate tariff structures, power factor correction (PFC), demand control and load time shifting. Data can be used to conduct tariff impact studies on the plant's load profile as the electricity supply industry undergoes major changes.

During peak times on the MegaFlex tariff package, for example, users pay 50c per kilowatt hour, versus 8c in off peak times. PowerSmart comes with all the SA energy tariffs pre-loaded, enabling users to run tariff impact studies using simulations of their usage at different times and across different tariff rates. Savvy plant managers can then operate plants during off-peak hours and schedule maintenance times, for example, during peak periods.

"Manufacturing plants frequently have energy bills that run into millions of Rands per month. With even a small reduction using the Adroit/PowerSmart combination, can bring about enough savings to pay for the project within three months," says Wright.

Recently, NC Automation installed an Adroit scada, PowerSmart package and energy meters at a large cement factory. The production process that forms the basis of cement is extremely energy heavy. To help control costs, the factory uses the system extensively for power factor control (PFC) as they attempt to even out the spike in their energy consumption and the heavy tariffs associated with these.

Energy data is fed to the plant's programmable logic controllers (PLCs), where, via a means of over-exciting synchronous motors, active power factor control has been achieved - reducing the energy peak maximum demands and associated costs. The system also is used to generate departmental or sub billing on actual use rather then rough calculations based on such things as floor space, so that companies can ensure an equitable distribution of costs between their business units.

PowerSmart software accommodates large scale automatic meter reading (AMR) via Ethernet networks, GPRS/GSM/landline modems and/or RS485 networks. It also enables the transfer of energy consumption data and events into an open ODBC database and of live energy readings from multiple energy meters via OPC into scada/PLC systems, which are used for displaying, trending alarming and possibly acting on the consumption data.

For more information contact Charles Hudgson, Adroit Technologies, 011 658 8100, [email protected], www.adroit.co.za

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved