In general, industrial scrubbers are designed to remove potentially harmful and polluting gas emissions from various types of industrial processing plants. These gases can typically be sulphur dioxide, chlorine, hydrogen chloride and hydrogen sulphide to name but a few.

Scrubbers operate by passing the toxic gas through a chemical solution that either dissolves or destroys the harmful gas by a chemical reaction. The spent scrubbing solution can sometimes be regenerated, disposed of in an environmentally friendly way or simply sold as a by-product. By-products can typically be sodium hypochlorite from chlorine scrubbing with caustic or gypsum from sulphur dioxide scrubbing with lime. There are a number of types of scrubber designs depending on the type of toxins and resulting neutralised residues. These can typically be:

* Orifice scrubbing.

* Venturi scrubbing.

* Fibre-bed scrubbing.

* Mechanical scrubbing.

* Impingement plate scrubbing

* Spray scrubbing.

* Condensation scrubbing.

Their individual designs and principal of operation is to be able to disperse as much toxic gas into the scrubbing solution, thereby maximising the chemical reaction.

To ensure the effectiveness and efficiency of the scrubber, the concentration of the scrubbing chemical must be maintained, pH, ORP and/or conductivity measurements are therefore used to monitor and maintain the strength of the scrubbing solution by blowing down and replenishing the solution.

There are two basic methods for wet scrubbing, 'batch scrubbers' and 'continuous replenishment scrubbers'. Batch scrubbers use a high concentration of scrubbing chemical and only flush or blow-down once the chemical has been spent, while continuous replenishment scrubbers blow-down and replenish the scrubbing chemical to maintain a consistent lower level of concentration. In order to effectively and efficiently control the process, various analog and digital points have to be closely monitored, controlled and alarmed, these would typically be levels, flow, pH/conductivity and/or ORP, pumps, fans, valves and switches, along with their run, trip, and/or position status.

With new legislations being passed worldwide and hefty fines being imposed on industries exceeding permitted gas emissions levels. Scrubbers are playing a key yet vital roll by protecting the atmosphere and environment.

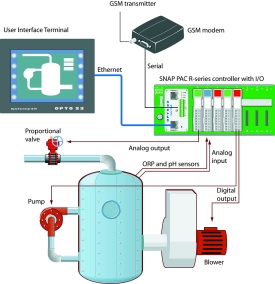

Thuthuka Group, a leading process engineering and project management company, provide turnkey solutions for most wet scrubber types. This company has partnered with a number of subcontractors that are leaders in their field of expertise to provide the total solution. Opto Controls is a supplier and integrator of the Opto 22 range of industrial Ethernet-based SNAP-PAC programmable automation controllers (PAC) and the fully integrated ioProject software suite. These products combine with the Opto 22 line of SNAP I/O modules to provide a complete system for achieving the necessary analog, digital and serial control needed for the monitoring, logging, control and alarming of the numerous field devices and operator interface terminals and much more. The Opto 22 hardware can also provide GSM support for remote alarming via SMS. The diagram illustrates a typical control overview of a scrubber.

For more information contact Mike Harrison, Opto Controls, 011 792 5232, [email protected], www.opto.co.za

| Tel: | +27 11 792 3560 |

| Email: | [email protected] |

| www: | www.opto.co.za |

| Articles: | More information and articles about Opto Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved