Rockwell Automation offers Rockwell Software factory management software that has wide application in the automation process. A recent use of Rockwell Automation's Arena simulation software illustrates the importance of simulation as a tool that can be used in many process automation projects to reduce risk, save money and compress the project cycle.

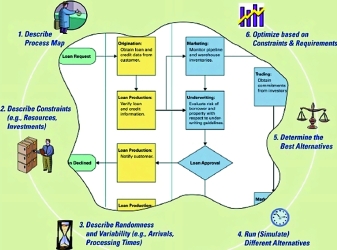

Simulation can provide a proof-of concept in advance of major project expenditures. It can also be used to provide a cost/benefit analysis and a risk assessment for different design approaches. Simulations are created by building a model of the proposed process, usually by using PC-based software packages.

When a frozen pancake manufacturer approached US company, Span Tech LLC for a conveyor system, Span Tech employed Rockwell Automation's Arena simulation software in order to minimise the risks and determine whether it could deliver the solution, before committing to the project.

Span Tech LLC in Glasgow, Kentucky, makes chain-curving conveyors for clients in the food, packaging, pharmaceutical and manufacturing industries. Its clients want to cut time spent handling product and reduce labour costs, product damage and downtime.

The pancake manufacturer required a conveyor system that would reduce the number of jams that occur when multiple lines of pancakes merged into a stacking area. With the existing conveyor system, pancakes exited the freezer randomly distributed. Span Tech determined that the pancakes needed to emerge from the freezer in six controlled streams. The system needed to stack the pancakes six high and merge the stacks onto a single-file conveyor. Product damage directly attributable to the new system could not exceed 0,2%, and the system needed to have a runtime efficiency of 96% or better.

Using Rockwell Software's Arena simulation software, Span Tech created an initial design concept to help calculate product manufacturing variables. According to Leo Schroeder, Span Tech president, "We chose Arena because we needed to determine project variable specifics and minimise risk. We wanted to know before contract acceptance if we could achieve project goals."

Span Tech first prepared an AutoCAD layout of the project and sent it to Simulation Modeling Services in Lisle, Illinois. Simulation Modeling prepared a schematic with flow rates, frequencies and product distribution. This information was then used to program an Arena simulation.

"Arena's simulation capabilities allowed the manufacturer to see the operation dynamically and increased customer confidence," says Simulation Modeling Services president, Rainer Dronzek. "It also assured Span Tech that its design solution would work, and it showed what kind of improvements would result in the manufacturing process."

The Arena-driven simulation convinced the pancake manufacturer that this was a viable project, and Span Tech completed the design phase. The new conveyor system met customer goals. With Arena, Span Tech optimised the process virtually. Because all the process changes and tweaks were done online, the start-up took only four weeks instead of months.

The result was a manufacturing process that decreased pancake product damage within requested parameters. The solution also reduced the number of employees required to monitor pancake production from four people to one. "Developing the simulation took more time at the beginning of the project, but it saved considerable time during installation, start-up and debugging," Schroeder says. "Costs for corrections made in the design phase of a project are miniscule when compared to making corrections during start up".

For more information contact Rudolf Van Wyk, Rockwell Automation, 011 654 9700,

| Tel: | +27 11 998 1000 |

| Email: | [email protected] |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved