Some months ago saw the launch of Wonderware's ArchestrA industrial automation application development framework in South Africa. ArchestrA is a five-year customer-driven initiative that provides the framework for new levels of ease of use, scaleability, project productivity and extensibility for industrial automation products and solutions developed on this platform. ArchestrA is also the most significant technology release from Wonderware in the past decade

"The customer visionaries who drove much of the direction for the development of the ArchestrA software architecture made it clear that project and application lifetime costs were becoming the major driving decision in software package selections," says Mike le Plastrier, MD of Futuristix-Wonderware. "Projected lifetime costs could even affect whether a project goes ahead or not. This is why, from day one, 'Architecture by ArchestrA' was designed to address the 'total cost of ownership' issue."

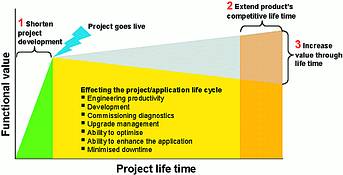

The figure illustrates how ArchestrA can enhance a project and application throughout their life cycles. Because ArchestrA is the foundation of Wonderware's Industrial Application Server, it can dramatically improve the efficiency of a project's design and engineering, especially when part of Wonderware's FactorySuite A2 offering (the 'A2' indicates the presence of the ArchestrA architecture). It does so through:

* Centralised namespace management throughout the application, which eliminates the need to synchronise namespaces between the system historian, system application server and any other aspects of the total system.

* The use of templates to build re-usable objects that can be reproduced and re-used. This means that standard components or entire systems (eg, a standard motor or complete conveyor system) once and re-use this many times over.

* The ability to make changes once and to propagate and manage change across the entire application. If changes are made to the parent object, the user may decide which children should inherit the change.

* Built-in deployment, avoiding the need to install software on different PCs. Deployment is now handled by the system. In this way, the need to load software onto remote PCs never arises. From a central management station, an authorised system administrator or end-user simply chooses the PCs on which the software should run and the software is automatically deployed.

* Powerful built-in diagnostics which help users better understand and tune their software and applications.

Where the Industrial Application Server and FactorySuite A2 really stand out is in the lifetime management of the project and application. This was a requirement driven by many of Invensys' larger customers in the definition phase, because it is critical that an application can be administered and managed after it enters production

Through its core framework, the FactorySuite A2 product line provides the foundation for extending the lifetime of an application, while keeping it state-of-the-art. As further versions of FactorySuite A2 products are released, lifetime costs will continue to be addressed. Some key features of the Industrial Application Server pertaining to extending the project lifetime are the abilities to:

* Add the Industrial Application Server to existing applications in order to address today's information requirements

* Absorb functional change throughout the project's lifetime. As production calls for new functionality, users can make changes and - unlike 'client-server' architectures of the past - can adjust their topology to optimise the application as a whole. For example, if a client needs to add a new production line and the current system is already heavily loaded, the user simply adds more computing power and drags and drops the part or parts of the application to this new PC. No client software needs to change as the total application remains as one single 'galaxy'.

* Add new functionality isolated from the rest of the application, so a portion of an application can be taken offline for modification and then be re-absorbed into the running application complete with changes. This is crucial to ensure that the complete plant remains operational while small sections of the plant are updated on line.

"All of the above enables existing applications or new applications to evolve over their lifetimes, thereby increasing the effective life-time of the application and increasing return on investment," says le Plastrier.

For more information contact Mike le Plastrier, Futuristix Advanced Control Systems, 011 723 9900, [email protected], www.futuristix.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved