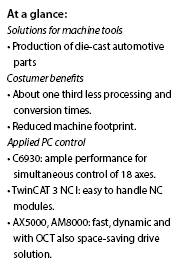

Swedish equipment manufacturer Ecmec AB has developed a high-tech machine for a supplier to the automobile industry that can complete several process steps simultaneously without having to remount the part being worked. The machining centre is designed for high-volume production of up to 200 000 parts per year and performs its functions and processing steps simultaneously within the same cycle. The machine reduces the previous processing and conversion times by more than one third, while requiring less of the valuable shop floor space with its reduced footprint. Beckhoff supplied TwinCAT 3 automation software for the Ecmec machine’s PLC and NC operations as well as the main spindle and forward-feed drives.

Founded in 1983 and located in the Swedish city of Växjö, Ecmec AB produces hydraulic and mechanical fixtures, accessories for robot grippers and customised machines for assembly, part handling and machining operations. The latest example is the newly developed Ecmec SPM (special purpose machine) machining centre, which integrates and simultaneously executes all steps for processing up to 200 000 pressure die castings per year for the automotive industry.

From the drawing board to the finished machine in record time

When equipment manufacturers design a customer-specific machine, they must keep an eye not only on component costs but also on development expenses. For this reason, the time from first draft to delivery should be as short as possible. “Since we don’t build a machine of this magnitude every day, we looked for a partner who could supply control and drive components designed to meet customer requirements,” says Daniel Eklund, managing director of Ecmec.

The challenges were considerable. Parts that were previously made on two machine tools with three to five axes had to be processed by a single machine operating 18 NC axes simultaneously. Two main spindles are designed as four-axis units, meaning they can move freely along the X, Y and Z axes as well as rotate and tilt. Another three main spindles move as three-axis units supplemented by an additional one-axis main spindle. With this configuration, workpieces can be machined on all sides without having to be remounted. A tool changer with four different tools makes the design even more flexible.

“The Ecmec SPM employs a totally different set of processing methods compared to traditional machines and does everything much faster,” explains Eklund. “It processes the workpieces roughly 33% faster than conventional machines and requires less machine footprint.”

Precise motion control with faster response times

“Addressing all 18 axes simultaneously requires a fast and powerful control system which is where Beckhoff came into play,” says Eklund. “To avoid interface problems, we looked for a solution from a single source, and Beckhoff was able to meet all the customer specifications.”

The flexible hardware design was another reason for the decision to select Beckhoff technology, because it made a big difference for the project group. “We ran through various alternatives, but the NC I software modules from Beckhoff represented the best option. The Beckhoff system is very powerful and easy to operate, which is something we truly appreciate. It is a prime example of German engineering,” adds Eklund.

At the core of the machine is TwinCAT 3 NC I software, which controls the six mechanical spindles simultaneously. The numbers of axes and channels were adjusted to satisfy the application’s requirements with respective option packages. As a highly scalable system, PC-based control also provides the best possible hardware platform for this application. The TwinCAT real-time kernel and the ultra-fast system communication over EtherCAT offer ideal conditions for high-precision motion control. Eklund explains: “This platform provided very fast control properties and a much faster response time than the conventional PLCs we used in the past, which was one of the main reasons why we selected PC-based control technology from Beckhoff.”

In addition, the TwinCAT development environment provides numerous features that make the designer’s work easier. For example, Ecmec’s programmers developed their own control and machine software on the basis of TwinCAT 3. They also opted to use the syntax with G and M-codes as defined in the DIN 66025 standard, which makes it easier for the machine operators to change setups for new workpieces. These and other features enabled Ecmec to develop this high-performance machine in a very short timeframe.

Control and drive components from a single source

The Ecmec SPM is controlled and operated via a C6930 control cabinet Industrial PC with a custom-designed CP3921 multi-touch control panel featuring pushbutton extensions. The user interface is TwinCAT HMI for NC processing, which is easily programmable based on standards such as .NET. The axes and I/O channels are configured via TwinCAT Engineering with NC I functions.

The two main spindles are equipped with AM8000-series servomotors with speeds of up to 11 000 rpm. The other four spindles ensure a high degree of processing efficiency for downstream processing steps as well. The maximum feed rate is 30 m/min, and the maximum acceleration rate is 0,2 g. The six main spindles and 12 servomotors are controlled by Beckhoff AX5000 servo drives for exceptionally fast and dynamic positioning. In addition, One Cable Technology (OCT) saves a significant amount of installation space.

To protect the operators and avoid equipment collisions, all servo drives are equipped with AX5805 TwinSAFE cards. The machine also uses TwinSAFE terminals and the EL6900 TwinSAFE Logic terminal with certified safety function modules and Safety over EtherCAT (FSoE).

For more information contact Michelle Murphy, Beckhoff Automation, +27 11 795 2898, [email protected], www.beckhoff.co.za

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved