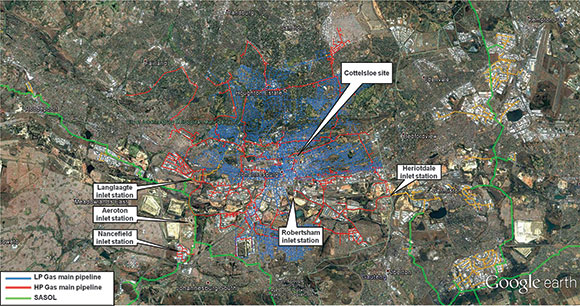

Egoli Gas is a natural gas supplier based in Johannesburg and servicing more than 7500 domestic, central water heating, commercial and industrial businesses in the area. The company operates an 1800 km network dating back to its origin in 1892.

The company acquires natural gas from Sasol, which is stored at a secure facility in Langlaagte where it is carefully monitored and controlled. The gas is then reticulated to the Cottesloe premises where it’s stored in low pressure holders before being reticulated to homes and businesses across the city.

With a ‘shop floor’ covering the greater Johannesburg metropolitan area, Egoli Gas had an understandable problem reading its meters and getting a grip on the true status of the vast pipe network. Today, manual data collection is a thing of the past and Egoli Gas can do a better job of looking after its customers by meeting their needs in real time.

Background

Prior to the installation of the new system, Egoli Gas personnel would drive to 7500 gas meters in the 1800 km network. They would log the consumption data for processing in Excel, from which very basic reports were generated for management.

This entirely manual process was prone to human error, unsynchronised meter readings and further time delays in generating the reports. The result was an inefficient operation and delayed response to issues affecting delivery to Egoli Gas’ clients.

“As a utility company with many important customers, our challenges were numerous,” says Emmanuel Matodzi, projects and planning engineer at Egoli Gas. “How do we read all the 7500 meters in our network and how do we ensure that none of the sectors in our network are being starved of gas or experiencing low pressure, especially in times of sudden demand from clients who use gas for power generation during load shedding?”

But that is only half the story. At any moment in time, Egoli Gas could not readily reconcile the volume of gas they bought from Sasol with the amount supplied to customers, until the tedious process of manual data collection was completed. The time and cost of personnel travelling the vast network had to be addressed.

And the list goes on: How could Egoli Gas prevent unwanted high pressures in its ageing network, which is not only undesirable for the network, but especially for those customers whose equipment may be designed to cope with 3 rather than 25 kPa? How can the company address the problem of detecting theft and leaks? Then there was the real need to know at all times how much gas capacity was in reserve, as well as the health of the entire network.

This was all about bringing decades-old, but vital, energy technology into the 21st century with all its attendant problems and challenges. What’s more, whatever solution was chosen could not rely on human intervention and had to be entirely trustworthy, since the profitability of Egoli Gas and the satisfaction of its customers depended on it.

Egoli Gas took a bold decision to address all these issues once and for all. Their goal was to develop a gas network monitoring solution using solar-powered GSM data acquisition technology and to log the data automatically in order to provide reports on gas distribution and consumption – all in real time while also addressing the issues of power availability at remote locations as well as that of vandal-proofing.

Implementation

The company selected Wonderware-certified system integrator Systems Anywhere for the implementation of this landmark project, which decided to build on Egoli Gas’ existing Wonderware-based industrial information infrastructure.

Systems Anywhere designed a cost effective solar powered vandal-proof logging station (Smartoos) for use at all measuring nodes to log gas volume, pressure and temperature, in order to determine the gas supply conditions at all these delivery points. Readings are transmitted via private APN every 2 minutes to the Cottesloe Starfish with a port-forwarding configuration.

“This alone resulted in huge savings in terms of personnel and travelling costs, as well as time,” says Matodzi. “In fact, we estimate the time and cost savings to be about 95% with a similar improvement in the quality of data – not only in its accuracy but also in its near real-time delivery. The system also provides every department with the information they need. For example, account managers now know precisely what their key accounts are doing, and can advise them accordingly. Our own account-ants now also know precisely how much gas we’re importing and distributing.”

The first glimpse into what is happening in Egoli Gas’ network is the overview of its 24 governor stations whose job it is to reduce mainline pressure to what consumers need – like a step-down transformer in an electrical network. This InTouch screen provides a concise view of current conditions and alarms. The elimination of all manual data collection lets personnel concentrate on improving customer service through the early and rapid detection and identification of irregularities in the gas distribution network before they become a problem for end-users. This is especially applicable to those users who use gas for power generation.

“This information also allows us to look after our ageing pipe network to ensure that pressure does not exceed 25 kPa, but is maintained above 16 kPa on the high-pressure mains,” says Matodzi. “This level of data acquisition and analysis means that our personnel can focus on real issues and on maintenance, rather than on data collection.”

Results

• Considerable reduction in personnel time and travelling costs.

• Personnel expertise can be used elsewhere.

• Accurate monitoring of pressures to look after customer requirements and the network’s safety.

• Only one person is needed to check irregularities and maintenance visits have been reduced to twice a year.

• Accurate measure of gas consumption for major clients vs what is bought from Sasol.

• Trends and alarms ensure speedy response to faults/issues.

• Egoli is quickly apprised of healthy/unhealthy parts of the network and can manage the supply proactively.

• Since the system is scalable, additional capabilities will include the detection of leaks and illegal taps.

“Thanks to Systems Anywhere’s ingenuity and Wonderware solutions, we are now one of the best utilities in Johannesburg,” concluded Matodzi. “During load-shedding a major bank customer thanked us for our reliability and swift response in meeting the requirements of their tri-generation plants, all thanks to our informed personnel and information suppliers.”

For more information contact Jaco Markwat, Wonderware Southern Africa, +27 (0)11 607 8100, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved