The measurement of electrolytic conductivity is the most frequently used electrochemical measuring method in industrial process measurement besides pH measurement. For about 30 years, conductivity for controlling CIP systems has been successfully used in the food industry. It has proved to be the best solution for concentration upgrading and separating water and alkali or acid and water in the cleaner return pipe.

Optimal cleaning agent concentration is one of the main conditions for the proper functioning of a CIP system besides the correct size of pump (flow rate of cleaning agent greater than 1,5 to 2 m/s).

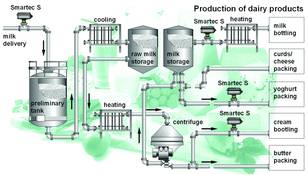

The Smartec S system (available from Endress+Hauser) for inductive conductivity measurement in the food industry achieves savings in time and cost by offering the cleanest techniques achievable, which in turn allows higher process safety with integrated temperature control and less waste water because of immediate response of temperate sensors. Conductivity is dependent on the type of substance dissolved (weak acids, strong alkalis, aqueous saline solutions and the electrochemical bonding characteristics (valency, ion mobility, degree of dissociation)). This is why the electrical conductivity increases linearly with rising concentration, provided there is a rise in the absolute number of freely moving ions in the solutions.

The figure shows the dependence of various alkalis and acids as a factor of their concentration at 20°C reference temperature.

Smartec S is supplied with four concentration curves. These are for sodium hydroxide (NaOH), nitric acid (HN03), sulphuric acid (H2S04) and phosphoric acid (H3P04) in the concentration range required for CIP systems. Four additional tables can also be entered for the cleaning agents used in a particular application. This ensures optimal monitoring and adjustment of the cleaning agent concentration at any time.

Smartec S is a maintenance-free measuring system. It is self-monitoring and regularly checks the function of its sensors and components. If an anomaly occurs, the instrument immediately generates an alarm via a separate relay. The polished stainless steel housing is protected to IP 67 and is fitted with a large formed seal (EPDM) and a breathing membrane (Goretex filter). The Smartec S is therefore suitable for operation in damp locations subject to alternating temperatures. The instrument is designed so that it can be sprayed by high-pressure cleaners, which are normally used in the food industry.

Many production processes, such as media separation in the cleaner return pipe of CIP systems, product replacement and bottling, have the problem of displacing one liquid product by another, mostly water, out of a pipe. Since piston flow cannot be implemented, a number of mixing or transition phases take place between the two media.

The product or water is then detected during the mixing phases by measuring the electrical conductivity. Contrary to other methods, which measure fluorescence or turbidity, the conductivity measuring method can measure concentration curves at a constant accuracy in clear media (water, beer, wine, juices) or in turbid products (milk, yoghurt, spices, naturally cloudy fruit juices).

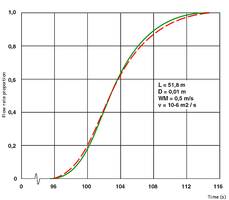

The figure above clearly shows that the mixing phase in a pipe flows through very quickly. For this reason, it is vital to use a fast-response measuring sensor and a fast-response temperature sensor since liquids to be rinsed out are very seldom at the same temperature as the rinsing water.

The sensor - made from injection-moulded polyetheretherketone (PEEK), which is chemically, mechanically and thermally resistant - has no joins or undercuts to avoid biological re-infection caused by the formation of nests. A V4A temperature sensor, which can track a 90° change in temperature in less than 8 s, is routed out of the PEEK material for the purposes of rapid temperature compensation. The sensors can be used at continuous temperatures in the range of -5 to +125°C - and withstand up to 140°C during sterilisation.

Smartec S is available with all customary process connections, as well as DN 50 sanitary tube union, 2" clamp, 2" SMS, APV and Varivent flange. Special sterile connections are also available as a custom technical solution. Equipped with the remote measuring range changing, it is specially designed for the application of media separation. This function allows the definition of the separating point and temperature compensation factor for each of four products in order to ensure the high-precision separation of each medium.

Options include 4 to 20 mA current output, Hart protocol, as well as customary bus protocols such as Profibus-PA, Profibus-DP and Foundation Fieldbus (soon to come). The technology can also be demonstrated on prospective clients processes, on request.

Endress+Hauser

(011) 262 8000

© Technews Publishing (Pty) Ltd | All Rights Reserved