We are increasingly living in an ‘always on’ society where we demand and expect 24/7 access to any and all information. But isolated items of information on their own are no longer enough. We want intelligent information that is presented in the context of what we are looking for. For example, satnav is all very well but I also expect to be informed of predicted traffic patterns on the way to my destination and suggestions on how to avoid congestion. And this also applies to control systems where we are starting to expect predicted KPIs rather than simply the current status.

While disconnected items of information are rarely as useful as they should be, the same can be said of disconnected enterprises which were always meant to be unified entities where each department contributed towards a common goal. Going further, globalisation demands that international companies still behave like unified entities as if geographical boundaries did not exist. This has led to the concept of Remote Operations Centres where centralised expertise can be concentrated and where performance can be monitored in a national or international context.

Right now, we are awash with brilliant technologies but how are we to make sense of everything that’s happening and use it to our advantage?

Key enablers

The Internet of Things

“In the next century, planet Earth will don an electronic skin. It will use the Internet as a scaffold to support and transmit its sensations.” These words were uttered by Neil Gross in 1999 – and he wasn’t wrong. Today, the Internet is not just for people (currently estimated at about two billion subscribers). It is also interconnecting devices in ways that most of us are unaware of. By 2020, it is estimated that there will be 50 billion objects connected to the Internet.

And phones are not the only devices getting smart. Everything from sensors and actuators to packaging machines are getting cleverer through improved communications, self diagnostics and more.

The cloud

Expanding or updating industrial automation systems normally requires additional hardware and software which has to be motivated as an operational expenditure. But it has been shown that acquisition costs are only the tip of the expenditure iceberg. The real money drain comes in the form of system maintenance, IT labour costs, disaster recovery contingencies, system backup, support, security, management tools – and the list goes on. Using the cloud not only eliminates hardware acquisition costs but most of the others as well.

It is a safe bet that your mining or manufacturing company was never also intended to be a computer company. So why not focus on what you do best and let others focus on providing you the computing services you need? After all, except in rare cases, you do not generate the electricity you use – you simply plug in and get on with your job. The same is happening regarding computing and information resources. Many companies will never have the resources to build the computing infrastructure they really need – especially regarding backup and security.

But these companies have no problem with that. Facebook, Google, Microsoft and others each have numerous server ‘farms’, each hosting hundreds of thousands of fully-backed up and secure servers. The scope of this technology is staggering and these resources are available to all of us.

In our field, this is especially relevant to system integrators who currently have to set up an entire computing infrastructure mimicking that of their clients in order to implement a new solution. If the client’s hardware and software infrastructure was in the cloud in the first place, none of this would be necessary and the new solution could be implemented and tested (including the FAT) from anywhere with a huge reduction in overall costs and time.

While the cloud may not be suitable for the real-time world of PLCs and real-time process control, it exceeds in storing, safeguarding and delivering the goods insofar as information is concerned. With that in mind, Wonderware’s Historian is now cloud-based.

Contextualised information

Information without context is of doubtful use and information without relevance equally so. Plant personnel need to know precisely that which is relevant to their tasks or intentions – no more and no less. This is the goal of a new product called Relevance.

Relevance uses Bluetooth, Wi-Fi, GPS as well as Quick Response (QR) and Near Field Communication (NFC) codes to identify plant personnel and to supply them with access to the relevant information they need at the right time depending on their roles. For example, an operator responsible for the running of a particular machine and needing to check something, can scan the QR code next to the machine’s HMI and the control system, recognising his responsibilities, will transfer a full version of the HMI onto his iPad so that he can continue his inspection while retaining control of the machine. On the other hand, a maintenance technician scanning the same QR code will be provided a read-only version of the HMI allowing him to perform his maintenance tasks without needing to constantly be in touch with the control room. If he needs to carry out maintenance on a motor, for example, he can scan the motor’s QR code and be provided with the necessary technical documentation. The same access and privilege rights apply to all other plant personnel such as supervisors, managers, etc.

Mobile information

Operators are not always in the control room and managers are not always in their offices – yet they need real-time visualisation/control of plant operations at all times. There is also an urgent need for remote operational support and maintenance as well as remote commissioning, testing and control equipment performance monitoring. Today, this is all done by providing qualified personnel with the access they need by using any browser on any device of their choice on any network (public or private) and wherever they might be. This is called InTouch Access Anywhere.

Information that matters

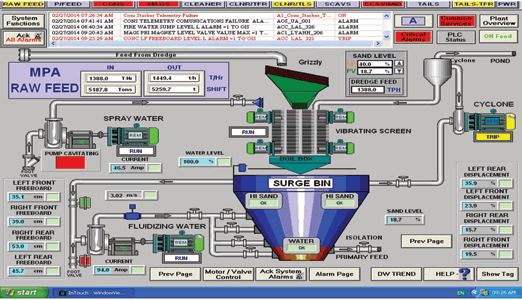

The primary interface with a manufacturer’s wealth creating processes is the operator, who, in turn, uses an HMI to see what is going on. If the HMI does not deliver the required information, there is going to be a corresponding dent in the generated wealth. Today’s operators are swamped with thousands of unnecessary alarms and dazzling displays that highlight the graphical creativity of their designers rather than their understanding of the real issues. In fact, after investigating the causes of a horrific series of explosions at a US refinery, the US Chemical Safety and Hazard Investigation Board (CSB) came to the conclusion that the mimic used in this instance was partly to blame and was ‘essentially just a PID segment sprinkled with live values’.

Applying the concept of situational awareness to HMIs changes everything. This new paradigm allows operators to perceive what is going on at a glance, understand what’s happening, predict what is going to happen and make an informed decision on the best action to take for a successful outcome – all without scrambling to attend to hundreds of alarms or trying to scan dozens of flashing numbers in a cluttered display.

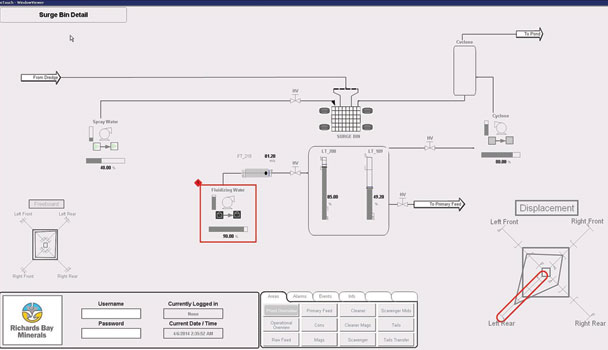

Here’s a real-life example: Figures 1 and 2 show the original and new level 3 Surge Bin graphic at Richards Bay Minerals. Note that there is no attempt to reproduce how any of the plant items (pipes, valves, etc.) look in reality as in the original graphic. Only the key operational parameters are shown and values are represented graphically as much as possible.

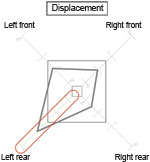

For example, at the lower right of Figure 1 is a symbol showing displacement – this is known as a ‘Polar Square’ symbol (magnified in Figure 3) which is part of the standard situational awareness library supplied with InTouch 2014. Ideally, the four values should be between the small centre rectangle and the larger one but the ‘Left Rear’ value has exceeded the prescribed limit. Not only is this anomaly immediately visible because of the distorted shape (rather than a bunch of numbers), but it is highlighted in red to show that it needs urgent attention.

Getting the right information

One thing that today’s forward-looking mining or manufacturing enterprise can’t complain about is a lack of databases at their disposal – each one a custodian of valuable information but for its own area of expertise: MOM, LIMS, operations, MES, batch, recipe management, etc. and then there are the databases created by custom applications – not to mention the databases trying to collate information from other databases. Of course, all databases provide reports but customisable or not, these reports don’t tend to cross database boundaries. From their suppliers’ point of view, why should they? But from your point of view, you must cross database boundaries as a matter of course to collate the decision-support information you need from a single version of the truth.

That is easier said than done because during this collation process, calculations will have to be made and new information may have to be entered manually. In addition, information sources will tend to be numerous and site-centric whereas the dissemination of results will tend to be enterprise-wide. This leads to a scenario where we have the need for an operational data store for the collection, aggregation, manipulation and validation of information as well as a data mart which will be the source of analyses and reports. To perform both these functions, Wonderware has two products – Intelligence and Flow – that allow cross-database aggregation, analysis and reporting of contextualised information from the same sources.

New releases

Wonderware has already introduced some new releases for 2014. These include:

Recipe Manager Plus – a web-based solution for users who don’t need the full-blown functionality of InBatch but need something more than the recipe management facilities provided by InTouch. It also integrates with any HMI, scada or control system.

InTouch 2014 – featuring a complete situational awareness symbol library providing more than 25 000 unique combinations including trends, spark lines animated polar stars and more.

System Platform 2014 – now includes a standards library that can be exported as protected objects across multiple projects.

Historian – can now handle up to two million tags

The following are scheduled for release later in 2014:

InTouch 2014 R2 – incorporates all the features of ArchestrA graphics within the InTouch environment without the need to purchase any ArchestrA licence. This is but one of a number of powerful enhancements.

System Platform 2014 R2 – will include seamless (no downtime) upgrades, improved diagnostics, a unified object namespace and many other new features.

For more information contact Jaco Markwat, Wonderware Southern Africa, +27 (0)11 607 8100, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved