Yokogawa Electric Corporation’s new ‘Wireless Anywhere’ business concept is based on the plant-wide use of ISA100.11a compliant wireless communication technologies for both monitoring and control applications.

This new system has been developed in line with the organisation’s ‘Grow’ concept of assisting customers through continuous evolution and the offer of timely solutions. The ‘Wireless Anywhere’ offering is based on three core tenets:

* Reliability: reliable high-performance field wireless and redundant technologies.

* Flexibility: flexible architecture that supports the full range from small to large-scale plants.

* Openness: open ISA100.11a standard that allows third-party field wireless devices to be connected.

Advantages of the next-generation field wireless system

Although most field wireless systems are currently installed in relatively small areas, demands are rising for increasing the number of monitoring points, covering wider areas, and expanding to process control as well as diagnosis, monitoring, and measurement.

To respond to these demands, Yokogawa has developed a large-scale, reliable, next-generation plant-wide field wireless system, which will manage up to 500 wireless field devices.

Conventional small field wireless systems are mainly installed as additional monitoring tools in areas with a clear line-of-sight such as tank yards and wastewater treatment facilities. Such systems offer only limited advantages such as improved inventory management, reduced regular visual checking, automated environmental measurement and reduced wiring costs.

In contrast, plant-wide field wireless systems can cover both a large number of measuring points in a small area packed with production equipment, as well as the entire plant. This allows customers to set up wireless devices anywhere in their plants and manage data from those devices to improve plant-wide production efficiency.

Architecture of the large-scale, flexible, field wireless system

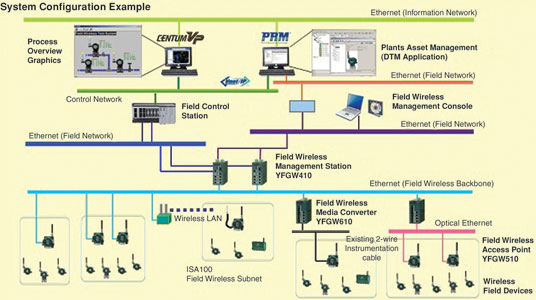

Yokogawa has developed the following new products as basis for the new field wireless system:

* YFGW410 field wireless management station.

* YFGW510 field wireless access point.

* YFGW610 field wireless media converter.

The existing YFGW710 all-in-one type field wireless integrated gateway, combines the functions of access points and wireless management enabling easy installation of small wireless systems.

In the new architecture, YFGW510 serves as an access point and forms the wireless backbone network with the YFGW410 field wireless management station. Therefore, by installing multiple YFGW510 field wireless access points throughout the plant, wireless sub-networks can be built and then connected to each other to create a large-scale, plant-wide field wireless system.

YFGW510 and YFGW410 can communicate via Ethernet, optical Ethernet, wireless LAN and instrumentation cable, allowing flexible installation across the plant. An example of the system configuration is shown in Figure 1.

Technologies to support a highly reliable field wireless system

Yokogawa Field Wireless has excellent receiving efficiency and the feature is high reliability of wireless physical layers (Reliable Radio). Now, the network layer reliability has been enhanced even further with the introduction of two new technologies.

1. Duo-cast

Duo-cast is a redundancy technology for the wireless path specified in the ISA100.11a standard. In the conventional mesh-topology network, if communication is not established in a path data is then sent via an alternate path. However, this may affect real-time performance because the data is not sent in the same time slot, but in a later time slot even in the same super frame.

On the other hand, Duo-cast simultaneously sends two identical data messages in the same time slot, provided either is successfully transmitted, real-time performance is maintained. Therefore, Duo-cast is ideal for ensuring the redundancy of mission-critical wireless paths and helps improve reliability while securing low latency.

2. Dual wireless backbone network

The network between the YFGW510 and YFGW410 is called a wireless backbone network. Its redundancy is specified by the ISA100.11a standard to improve the reliability of the network and is achieved by the redundant YFGW410 stations. Either of the dual YFGW410 stations can deal with disconnections and errors of the wireless backbone network, and malfunctions of the other YFGW410 (see the figure below).

Redundant stations, one set to Active and the other to Standby, are connected with each other via a synchronous communication cable. If any trouble in the Active YFGW410 is detected, the functions and data are quickly shifted to the Standby to continue communication.

Enhanced version of wireless transmitters

Wireless differential pressure/pressure transmitters and wireless temperature transmitters have been enhanced with the release of Plant Wide Field Wireless System.

The improvement of communication quality with detachable antenna

The detachable antenna type model has been released allowing high gain antennas to be used with these models through the antennas extension cable. The placement of antenna can now be optimised moving the location of the transmitters. Expansion of communication distances therefore becomes much easier to achieve.

The extension of battery life through lower power consumption

Due to more efficient transmission, the battery life of the detachable antenna type models becomes longer than the conventional products due to lower power consumption. Depending on conditions, 1,5 times to 2 times battery life is realised. Examples of extended battery life include:

* EJX B series wireless differential pressure/pressure transmitters: 10 years at an update rate of 30 seconds and 5 years at 10 seconds.

* YTA510 wireless temperature transmitters: 10 years at an update rate of 10 seconds and 8 years at 5 seconds.

Summary

Yokogawa has been researching and developing industrial wireless technologies for 10 years and has compared a variety of standards with the following conclusion: In the field of industrial measurement and control, wireless physical layers must eliminate instability as far as possible (Reliable Radio) and the system architecture must reinforce this.

Among various industrial wireless communication standards, the ISA100 variants were found to be most suitable for achieving Yokogawa’s policy and it has therefore been adopted.

Yokogawa has subsequently released various wireless applications while its development engineers have visited over 100 sites worldwide for survey. The accumulation of such experience, together with information obtained from many customers, has been reflected in a development that takes full advantage of the strengths of the ISA100 standards as the basis for plant-wide wireless monitoring and control networks.

Application: temperature and pressure monitoring in an oil refinery

Requirement

To monitor the temperature of the reactor and the pressure of the circulation filter located about 80 metres from the control room. Although the distance is not extreme, there are many pipes and tanks in the path to block the transmission.

Solution

A repeater was installed at a high point between the monitoring position and the control room. The resultant multi-paths created between the repeater and the temperature and pressure transmitters allowed the signal to ‘jump over’ the obstructions to reach the antenna of the gateway at the control room.

Application: measuring temperature in a rotating furnace using the YTMX580 multi-input temperature transmitter

Requirement

A company uses a rotating furnace in the titanium oxide manufacturing process. It wishes to install multiple temperature sensors directly on the furnace in order to measure the internal temperature with high accuracy.

Solution

Installing a YTMX580 transmitter on the side of the furnace allowed measured values from multiple temperature sensors to be communicated wirelessly – see Figure 2.

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved