Whether for cooking, flavouring, in margarine or any number of other uses, we come in contact with edible fats and oils every day and their manufacture follows critical health and quality criteria. As a leading producer of edible fats and oils, Hudson and Knight recognised the need to upgrade their extensive supervisory system to provide operators a greater degree of insight into complex processes, to lower the total cost of ownership and to cope with changing product and market demands.

Background

Hudson and Knight found itself with an outdated supervisory system that was difficult to maintain and improve, was not based on object oriented technology (OOT), had no built-in development security and auditing facilities and no server scripting facility.

Constant changes in technical staff meant that the system standards started to diverge because updating of the redundant servers could often not be synchronised with the result that the quality of the system was slowly being eroded. At the operational level, a lack of understanding of the process coupled with a non-intuitive control system was affecting downtime and production efficiency.

The process

The plant receives various crude and semi-refined oils from an on-site sunflower seed mill and from tankers with material sourced from all over the world.

All oils refined at the Hudson and Knight refinery go through a process of refining and deodorising to remove any odours that could taint the customer’s finished product. Seed oils are then subjected to a winterising process to remove any waxes which could cloud the oil if chilled. Oils that are destined for deep frying then have antioxidants and antifoaming agents added to them to enable them to handle the treatment that they will receive when heated to temperatures in excess of 180°C for hours on end in the customer’s fryers.

The processed oils are then shipped to on-site customers (eg, for margarine production), tankers for national distribution and to packaging lines for the retail market.

Solution selection

It was decided to replace the supervisory system with one that is:

* Truly object orientated and secure – this would enable improvements to be made easily and in a controlled fashion so that standards would be protected and maintained at all times. This would also protect the investment made in the new control system. The ability to add improvements easily would also facilitate a lower-cost, continuous optimisation process that would address the skill levels of operational staff by providing them with more pertinent information and a control system interface that was easier to understand.

* Reliable and scalable – Wonderware’s ArchestrA (V2 and V2.1) has a proven track record of coping with small as well as very large systems. “We have one system running 350 000 I/O successfully,” says Martyn Daniels, operational unit manager at Quad Automation (chosen system integrator for this project). “We also know that the redundancy system works very well. On the old system, there was no automatic changeover of servers.”

* Managed and server-side scripting code – this would enable the protection and securing of source code all in the same environment and there would be less need for externally-developed ActiveX code and controls and their maintenance. Server-side code would enable common functions to be implemented at the back end making the job of plant-wide changes far easier. Server-side coding would also help in reducing the duplication of code, using the high-end server hardware more effectively and lowering the hardware specification of clients together with the complexity of setting them up.

* Minimum downtime – any changes and improvements to the new system would have to be done with the minimum production downtime by using scheduled stock-takes while the old system would still be in operation should it be required.

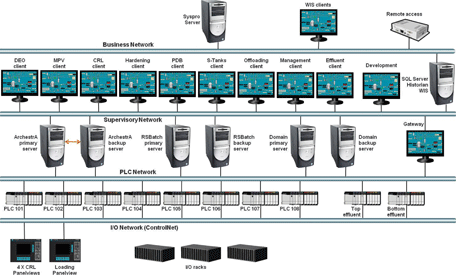

Hudson and Knight chose system integrator Quad Automation. Software solutions selected for the new system included the Wonderware System Platform based on ArchestrA technology, InTouch HMI/Scada, Wonderware Information Server and the Wonderware Historian.

“Selecting ArchestrA technology and its components would also allow for better integration of other subsystems such as InBatch, Formulation Management Module, Performance Software and the Manufacturing Execution (MES) module,” adds Daniels. “This would result in a further reduction of customised engineering and third-party components as well as a reduction of the need for maintenance and technical skills.”

Implementation

Careful attention was paid to defining an accurate area model of the plant for three important reasons:

* Operators were to be notified of problems in their areas of responsibility only. In the past, operators would be confronted with hundreds of alarms, the great majority of which were not their responsibility. The operator’s login data provided the system with the necessary information to do this selective alarming.

* Easier future application of area-based functions. These include intelligent and conditional alarms and events as well as SOP and HAZOP handling.

* Easier future application of MES. An accurate and detailed area model would facilitate the deployment of manufacturing enterprise solutions.

Equal attention was paid to the design of the derivation model which involves detailed Object Oriented modelling that would enable global changes to be made quickly and precisely.

Solutions were developed for event sequencing, formulation management, batch scheduling and materials management. “The refinery is an intricate plant where different oils can be routed virtually anywhere, which adds another level of complexity to materials management,” says Daniels.

Raw materials, WIP and finished goods are stored all over the plant and there are many routes leading to and from these tank farms which are connected to several processes that can transfer these products in or out at any time. The status, quality and age of all materials is monitored and reported on by the control system. Access to the tanks is governed by strict rules which are enforced to prevent contamination. “This is extremely important, especially when some of these raw materials can cost as much as R50 000 per ton,” says Daniels.

ArchestrA object capability allowed these rules to be implemented and enforced in a structured fashion which is easy to maintain. This object capability also allowed the implementation of a real-time material search algorithm which assists operators in finding valid tanks quickly and reliably.

Information integration

Large amounts of data are being stored by the system including all the historian data which is used for real-time trending purposes as well as all material transfer and batching transactions. Other data include data logs of laboratory analyses which can be entered after completion of the batch, automatic stock take and quality analysis of all tanks as well as the logging of all raw material receipts and dispatch notices of finished products.

“In the past, it has been costly to make this data available to operators where and when they needed it,” says Daniels. “ArchestrA is the enabler that is helping Hudson and Knight to make better use of all this information in a cost-effective and maintainable manner.”

Wonderware’s SQL DataGrid is used for displaying sequencing history (sequence/phase performance, analysis of delays, etc), device history (performance analysis of any or all devices – sequences, motors, valves, etc), status history (device states, tracking of manual operations – available on all devices) and material movement in and out of storage and process vessels (current stock levels, transaction history and on-the-spot mass balancing).

Benefits

* Enforced standardisation.

* Decreased downtime and callouts.

* Increased information to operators as well as to process and engineering personnel.

* Lower cost of ownership.

* Uses up-to-date technology.

* Off-the-shelf implementation.

* Ease of integration with third-party applications.

What is next?

While Hudson and Knight’s supervisory needs have been met, this project has, at the same time, laid the groundwork for the company’s real business needs which include:

* Conversion of Crystal reports-based MIS Intranet to Wonderware Information Server (WIS) and Microsoft Reporting Services.

* Wonderware Performance Software (Real-time OEE).

* InBatch V9.

* Wonderware Manufacturing Execution software.

All future enhancements have the mandate to ensure Hudson and Knight has the ability to react quickly to changing market conditions and customer requirements as well as raw material variances while being able to adopt the latest processing technologies and adapting to changing skill levels.

Conclusion

Effective industrial business management is more than throwing in a supervisory system and hoping for the best. These systems monitor and control the company’s fundamental wealth-creation processes and provide vital decision-support information at many levels. As such, they need to be agile and scalable. They also form part of a much broader picture and their design must include this vital aspect because, by themselves, they cannot do it all. A properly-designed supervisory system should never actually get old (except perhaps for the hardware). Its design should also ensure that its owner’s investment is protected by playing its role in the broader set of requirements of production companies (MES, ERP, MIS, etc). So, it is no longer just about supervisory systems. It is about the future, protecting investments and helping companies achieve their business goals rather than simply addressing process control needs.

For more information contact Deon van Aardt, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved