Orley Foods is fully HACCP (Hazard Analysis and Critical Control Point – an FDA programme) compliant and the company’s quality management system conforms to ISO9001. Compliance is audited regularly not only by Orley but also by the South African Bureau of Standards (SABS) and it is within this context of mandatory regulatory compliance that a material tracking solution was sought.

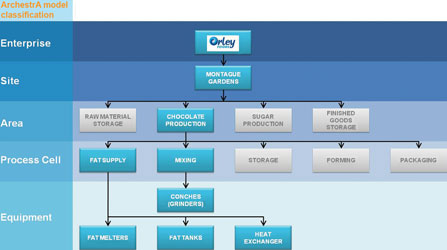

The Orley Foods plant is made up of four main areas (Figure 1). From Raw Material Receiving to Finished Goods, tracking and traceability is key to regulatory compliance. This is especially true of the chocolate manufacturing facility which manufactures chocolate in bulk according to the specifications of downstream chocolate confectionery manufacturers whose products are found in the retail market.

Project objectives

“Before this project, we were working with a failing system while our multinational customers demanded more traceability information,” says Henk de Villiers, operations manager, Orley Foods. “These large companies want certificates of analysis and conformity and can demand a full traceability report within two hours. They can also do flash audits on site without warning and ask any questions they wish about any batch. So we looked for a solution that would provide seamless and transparent integration of manufacturing and business systems throughout the company.”

The manufacturing system would have to be capable of as yet undefined expandability, ease of integration and the ability to provide data in context for the benefit of more informed decision-making. All the important, relevant and contextual information was to be published to a portal for easy access by personnel who could make best use of it and it was imperative that the system have the ability to trend and trace process issues in order to speed up trouble shooting while conforming to regulatory requirements.

Project requirements

In order to achieve its objectives, Orley Foods would have to implement some far-reaching initiatives that included the re-engineering of its process control and information delivery infrastructure. Some of the considerations included:

* Traceability of fat usage and additions against work orders – in the chocolate manufacturing process, the different fats used are incompatible with one another so it is vital to ensure traceability of the fat used at all times.

* Monitoring/logging of process parameters – the chosen system would be used to monitor and track process parameters in the plant and for each recipe batch.

* ERP integration with Syspro – Orley Foods needed one version of the truth for the bill of materials in order to minimise formulation failures and so needed this information to be fed directly from Syspro to the manufacturing system.

* Overall system upgraded to latest technologies – as the company’s system could no longer cope, it needed to upgrade to the latest technologies that would address its Network and Windows/SQL Server environment as well as its scada and PLC system needs.

* Ingredient management of recipes – As Orley Foods has over a hundred different recipes for liquid chocolate including different colours and fat combinations, the company needed a system that would be able to handle this variation seamlessly.

* Introduction of expandable reporting infrastructure – with the new business environment and the need for key information, Orley Foods developed KPIs to which the manufacturing system had to respond so as to deliver reports from a central source.

Solution selection

While realising that there were a number of potential technologies to address their needs, Orley Foods decided to look for prospective solution providers who could use the technologies they thought most appropriate to the task at hand.

“We started the project by defining our needs and then drew up a tender allowing various vendors and systems to be evaluated,” says de Villiers. “It was vital that we had a well-known system but it was equally important that we had a Cape Town based system integrator with experience in the development of PLC, scada and databases, especially SQL. It was also a prerequisite that the SI should have prior experience in a food and beverage environment and be well acquainted with the complexities of working in a HACCP environment. We chose AMR Automations because it met all these criteria.”

Several prominent technology suppliers were considered but eventually Orley Foods selected Wonderware. “We found that the Wonderware solution was best suited as it had a proven track record in food and beverage (we spoke to their customers) and was used in many local and international plants involved with food production,” says de Villiers. “We were also shown examples of integration between Wonderware production and control systems and our chosen ERP system, Syspro. Lastly, there are numerous system integrators and solution providers with an extensive knowledge of the Wonderware suite of solutions which meant that we would not be stuck in an emergency.”

Solution architecture

Wonderware’s System Platform, based on ArchestrA technology, was used to develop a model of the plant. “Although the project only addressed certain aspects of the chocolate production facility, we designed the model to cater for the entire plant,” says Stefan la Grange of AMR Automations.

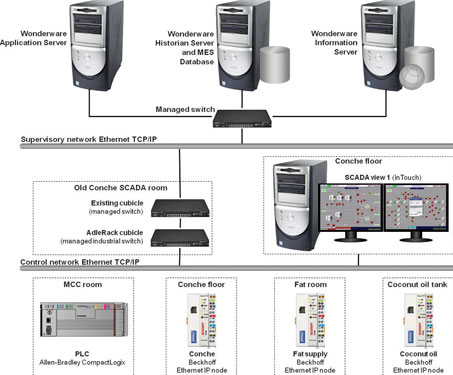

An important part of the project was the PLC upgrade where the previous PLC was replaced with an Allen-Bradley CompactLogix unit and Beckhoff Ethernet TCP/IP remote I/O units which AMR found to be a good and rapid solution for upgrading installations where PLCs could be kept out of harm's way.

“We design PLC programmes to run autonomously with no interference from the scada system,” says la Grange. “In this case, the PLC runs the recipe and handles the fat transfer route allocation. Obviously, processes for which the necessary raw materials (eg, fat) are not available are not started.”

Orley Food’s ERP system, Syspro, places the work orders into a ‘holding’ or intermediary Wonderware Historian production (MES) database from where they are picked up by the scada system. The works orders specify the raw materials to be used as well as the tank and equipment allocation and scheduling. Operators then use the dual-screen scada system (InTouch) to view the state of all the conches in the system and the works orders they are executing.

“We use the SQL data grid from Wonderware to show the production plan which displays the work orders that are queued or being processed and a click on the column headers sorts the display according to the chosen criteria,” explains la Grange. “Operators can modify the execution time of work orders or switch machines for a specific work order if authorised by production supervisors. This is useful for bypassing breakdowns or maintenance problems.”

The Wonderware Information Server reports tabulate all aspects of work order status and production information such as temperature vs. pressure charts, process variations, timings and operator interactions for traceability purposes.

Realised benefits

* Batch size consistency – previously, this could be a hit-and-miss affair with corrections having to be made for marginal or failed recipes. Today, that is all in the past.

* Raw material allocations tracked – previously this was done manually and prone to operator error.

* Better process control tracking – alarming (eg, motor trips) are now available at the scada level as is trouble-shooting information (temperatures, pressures, grinding times, etc,) as well as operator involvement.

* Significant savings in fat usage – in the chocolate industry, cocoa butter is called liquid gold because of its high cost.

* Standardisation of batch processing times – allows for critical evaluation of plant performance reduced consumption or resources, especially electrical power.

* Minimised batch/formulation corrections – savings in addition of raw materials to batches which could result in batches that were larger than the customer ordered and were therefore wasted.

Conclusion

Phase 2 of this project will capitalise on the gains already made and extend functionality across the entire plant while closing the loop with feedback directly into the Syspro ERP system. Orley Foods has shown itself to be a prime example of adaptability in a more demanding world with a globally-competitive marketplace. The integration of information technology at the business and production levels is helping the company deal with the mechanics of sustained profitability. It allows Orley Foods to focus on its mission to provide products that delight all of the market.

For more information contact Andrew Rennie, AMR Automations, +27 (0)21 534 0838, [email protected] or Deon van Aardt, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved