As part of its regulatory compliance the South African Nuclear Energy Corporation (Necsa) is required to monitor and record a massive amount of data from the Safari-1 research reactor. To support this Necsa requested Adroit Technologies to develop the required driver and test the limitations of the software. Adroit Technologies together with Beckhoff, implemented the Beckhoff ADS Sum command within the Adroit driver and achieved some phenomenal results. Tests were done at the customer site under controlled conditions.

System set-up

PC hardware: desktop server with Intel Xeon Core2Quad CPU @ 2,864 GHz and 16 GB RAM, VMWare image with Windows XP SP3 operating system. The VMWare virtual machine was setup with 1024 MB RAM allocated and two processing cores.

Beckhoff: AMS Router installed with TwinCAT version 2.10.0, TwinCAT System Version 2.10.0 and TwinCAT PLC Control version 2.10.0. The PLC Control is in Stop Mode and the TwinCAT System Control is in Run Mode.

Adroit: Standard Adroit 7.0.5 Installation with the latest Beckhoff Driver was configured in the following manner, a general mix of data types (per Necsa’s requirements) and Adroit Agents were used to represent a typical configuration, keeping the same ratios but increasing the tag counts:

* 25% Booleans.

* 25% Integers.

* 25% Reals.

* 21% User defined types (UDTs consist of 72 Bytes per UDT).

* 4% Strings (80 bytes per string).

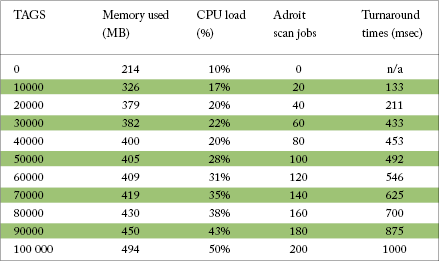

The Agent count was increased from 10 000 in steps of 10 000 until 100 000 tags were being scanned consistently and reliably. The general feeling amongst the developers and applications engineers was that a CPU load of more than 50% under these conditions would still constitute an unstressed system that would be considered an acceptable steady state condition. The test measured the following variables:

* Tag count.

* Memory usage.

* CPU Load at steady state.

* Number of scan jobs in Adroit.

* Turnaround times from Adroit to TwinCAT and back to the scada on all variables. See the table below.

The results were exceptional and opened the door for the Adroit/TwinCAT solution to customers requiring a platform for large high-speed data monitoring applications.

Beckhoff offers ‘open automation’ solutions with high-speed Ethernet I/O interfaces, and allows for scientific automation to be achieved through standard PLC hardware and scada software from partner companies.

High-speed bulk data monitoring and logging applications have unique needs. For many years customers required application specific hardware/software to achieve the speed/throughput from I/O through PLC, scada and database that was needed. The technologies employed by Beckhoff and Adroit in developing a joint solution for Necsa, demonstrated that an ultra high-speed communication driver could be developed to address these special process monitoring needs using standard components.

Beckhoff software background

The Beckhoff TwinCAT system architecture allows the individual modules of the software (eg, TwinCAT PLC, TwinCAT NC) to be treated as independent devices: For every task there is a software module (client or server). The servers in the system are the working ‘devices’ in the form of software; their operating behaviour is exactly like that of a hardware device. For this reason they are often referred to as ‘virtual’ devices implemented in software.

The messages between these objects are exchanged through a consistent ADS (automation device specification) interface by the message router. This manages and distributes all the messages in the system and over the TCP/IP connections, allowing all TwinCAT client and server programs to exchange commands and data, to send messages and transfer status information etc.

Specifically for the Adroit/Necsa application

ADS offers powerful and fast communication for the exchange of information between Beckhoff products, software or hardware, and a scada system. It is possible to read single variables or complete arrays and structures with a single ADS-API call. The ADS-Sum command reads with a single call, multiple variables which are not structured within a linear memory section.

As a result the ADS caller application speeds up cyclic polling, for example:

* Prior to ADS polling 4000 single variables which are not in a linear memory area (array/structure/fixed PLC address) would cause 4000 single read requests each of 1-2 ms protocol time. As a result the scanning of these variables took 4000-8000 ms.

* The Ads-Sum command allows reading multiple variables with one request. 4000 single variables are handled with e.g. 8 single Ads-ReadReq (each call requesting 500 variables) each with 1-2 ms protocol time. As a result the scanning of these variables now takes less than 16 ms.

Adroit managing director Dave Wibberly concludes: “This solution shows that Adroit remains a powerful scada offering that can be used in the most demanding of applications without compromising quality or stability.”

Readers wanting to know about Necsa please visit www.necsa.co.za

For more information contact Adroit Technologies, +27 (0)11 658 8100, [email protected], www.adroit.co.za or Kenneth McPherson, Beckhoff Automation, +27 (0)11 795 2898, [email protected] , www.beckhoff.co.za

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved