Heavy industry, such as mining, often makes use of large machinery such as boom bucket wheel stacker reclaimers. These are massive, distributed systems that could improve their productivity and efficiency with modern wireless networking technology, such as a WLAN link between the operator’s cab and the end of the stacker arm. However, if the connection is unreliable, then the advantages of introducing wireless communications are lost.

Coordinated activity is often crucial to the successful management of an intricate industrial process. More and more, system integrators are turning to wireless communications to achieve such coordinated solutions for highly distributed or mobile applications, such as stacker-reclaimers or underground mine cart systems. Common to these systems are constantly moving components, which make wired networks impractical. However, reliable communications have not become any less important; a network interruption can cause costly downtime and expensive damage, or even threaten the safety of the workforce.

Three major causes of wireless packet loss

Even in a properly configured wireless network, there are three primary sources of communications errors: collisions, weak signal, and environmental interference.

Collisions occur when multiple devices compete simultaneously on the same network segment. For wired Ethernet, transmitting stations can listen for incoming signals and notify the network if a collision is detected. Confident collision detection is rarely possible in wireless networks. While transmitting, a wireless station will most likely receive only the signal from its own transmitter, which is located closest to its corresponding receiver. This obscures any collisions from other stations. As a consequence, if packet loss is detected in a wireless network, the 802.11 protocol assumes that a collision has occurred, and responds with exponential back-off and adjustments of the retry counts.

Packet loss can occur due to a weak signal if the signal strength at the receiver is too weak for the data rate of the packet. Weak signals can be caused when the network attempts to transmit at a data rate that is too high for the signal strength, or because physical obstacles are making the signal weaker. Simple movement could also be the culprit in mobile applications if the client has moved farther away from the access points. The 802.11 protocol only begins to tune the data rate and power, or consider AP hand-offs after a collision has been ruled out as the cause of packet loss.

Environmental interference also contributes to wireless unreliability. Electronics such as cordless telephones, Bluetooth devices, industrial microwaves, or video senders all create interference on the 2,4 GHz band used in most 802.11 wireless networks. This radio interference reduces band availability resulting in packet errors.

Wireless redundancy

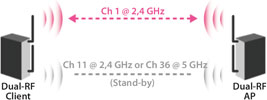

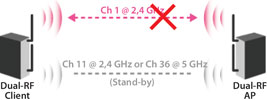

Creating a redundant wireless link does increase the reliability of the system. While one wireless link is active and transmitting, the other is on standby on a different channel, ready to take over if transmission quality drops below a certain threshold. However, this solution has its limits. First, it takes time to switch to the new link. Some packets will invariably be lost during this transition period. Second, if the threshold for activation of the standby link is set too low, then communications will need to drop to a low data rate before the current link is disconnected. This is unacceptable for applications that require a continuous and high level of performance. However, if the threshold is set higher to avoid this, the ‘ping-pong’ effect – where the wireless connection constantly switches back and forth between the two links – becomes a problem that increases the complexity of the switching mechanism.

Advanced wireless redundancy

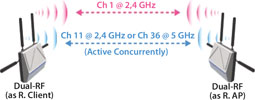

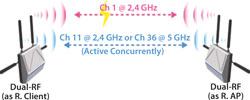

In order to avoid these complications, Moxa’s wireless products add advanced refinements to redundant wireless link technology. The AWK-5222 and 6222 feature two independent RF modules, which can be activated simultaneously. By working concurrently, the redundant wireless link duplicates the data transmissions and eliminates any packet loss from waiting for the connection to switch links. The ability to broadcast simultaneously on two distinct channels, and even two distinct bands (2,4 GHz and 5 GHz), also bypasses any interference that might exist in one band.

Simultaneous dual redundant links also increase the throughput by reducing the number of resend requests. Throughput is the average rate with which messages are delivered over a path. It is possible to have high data rate yet unsatisfactory throughput if a lot of communications ‘overhead’ is consumed on information such as frame headers and retransmission, leaving little room for actual message data to be delivered. Resend requests, which are a particularly prodigious source of overhead in wireless applications, can adversely affect throughput. Fortunately, with dual redundant links, data packets do not need to be resent as long as they are received on one of the two links. This minimises communications overhead, optimises bandwidth utilisation, and maximises throughput at any data rate and under any conditions.

Mines and industrial facilities are hectic places, with large machinery constantly in motion. The advantages of these advanced redundancy technologies become clear once they face the challenges of a demanding real world application such as a stacker-reclaimer. Moxa’s industrial 3-in-1 wireless AP/Bridge/Client products are ideal for the rigors of this type of application. The outdoor AWK-6222 can be installed as a client at the end of the belt conveyor to link the material handling PLC and IP camera via its dual Ethernet ports for video monitoring and data collection of bucket wheel status and digging conditions. This data can be transmitted to an AWK-5222 unit in the operator’s cab in both the 2,4 GHz and 5 GHz bands. The resilience of the redundant wireless connection and IP68 protection make these devices capable of overcoming the communication problems usually associated with these busy, bustling environments.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved