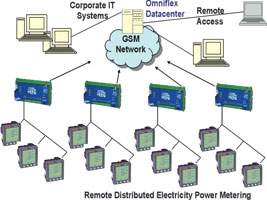

Omniflex has developed a system of scaleable telemetry outstations for GSM cellular networks to support general packet radio service (GPRS) transmission of data from remote outstations that require monitoring.

“The suitability of GSM networks has become a reality due to their coverage, reliability and low cost of ownership,” says Ian Loudon, Omniflex sales manager. “There is no infrastructure cost to consider as you have with in-house based systems and you can extend your monitoring country wide, in fact, it is possible to use the technology outside the country’s borders as well.”

Realtime advantages

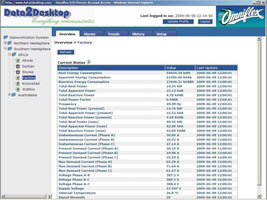

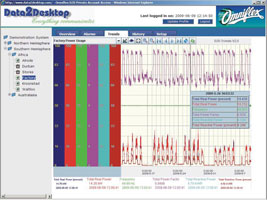

With power monitoring and power saving an issue at the forefront of management minds the application of monitoring technologies comes to the fore. Since all plants are billed on their power usage by Eskom, municipality’s etc monthly, via meter readings, it is often difficult to get timely consumption information. The surprise comes at month end when the bill arrives! Many plants do monitor the bulk supply and even have check meters in place to verify the billing meter, however, getting access to the data on say an hourly or daily basis is problematic and in many cases expensive.

The important issues to keep in mind are:

* Metering done at bulk level (main feeders) many have several bulk connections.

* Access to meter readings difficult (manual, networked).

* Consolidation of data difficult.

* Remote meters are difficult to reach with communications networks.

* Low resolution of power consumption within the organisation.

* No reporting to management allowing corrective action.

* High cost of implementing new systems.

* Large distributed organisations cannot easily consolidate the utilities bill over the group.

* Benchmarking. (How efficient are we?)

Loudon comments, “Most companies suffer similar problems when it comes to identifying where the waste is happening, how to monitor it and what to do. Managing the utilities bill is a concern for everyone, but often the responsibility is not allocated to anyone specifically. This not only applies to electricity but also water, air, gas and fuel-stuff.”

The Omniflex response

Omniflex has developed the web-based remote monitoring systems infrastructure to put data into the right hands by measuring and monitoring those resources, consolidating the information and automating the reporting process and alarm notifications. Empowering people to make decisions that save the organisation money.

Omniflex can integrate the system into management ERP or scada systems where necessary. Generally these systems are not manned 24/7 and thus the ‘always-on’ web-based monitoring with automated alarming and reporting has been implemented. The connection to ERP is ideal where these systems are integral to the day to day business operations, like vendor managed inventory.

Omniflex interfaces directly with plant metering through serial communications eliminating duplication of measurement. This, however, is reviewed on a site by site basis to allow for the constraints of each site and metering in place. A power audit is often the best course of action to identify the areas using the most power and thus increase the potential for savings.

The Omniflex solution comprises:

* 12-40 modular programmable remote terminal units (RTUs).

* Inputs and serial communications port for third party devices ie, electricity meters.

* Web-based monitoring for access from anywhere by anyone (with access rights).

* Automated reporting: daily, weekly, monthly.

* Direct SMS to service personnel.

* Intelligent power meters for monitoring the power consumption of the plant.

For more information contact Ian Loudon, Omniflex, +27 (0)31 207 7466, [email protected], www.omniflex.com

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved