The new release is the evolution of equipment downtime and overall equipment effectiveness (OEE) software and an integrated module of the Wonderware MES and supervisory software solution.

Performance Software 3.5 features an ArchestrA technology-based configuration and visualisation, providing a solution that is easy to set up for a single line, but capable enough to support enterprise-level asset performance strategies. The software is ideal for manufacturers that require a comprehensive equipment downtime and efficiency tracking solution that can be easily deployed across multiple plants.

The software is more than a point solution for downtime and OEE tracking. It is part of a unified supervisory and manufacturing enterprise solution (MES) that can evolve as a customer’s MES requirements grow, saving development costs and simplifying the number of applications that plant IT needs to service and maintain over the long term.

“When Cimnet was acquired, a key part of the strategy was to integrate the Cimnet Factelligence MES functionality with the Wonderware System Platform to unlock ArchestrA’s scalability and extensibility benefits to customers needing to monitor equipment downtime and OEE,” said Deon van Aardt, MD of Wonderware Southern Africa, a member of the EOH group. “This has now been accomplished with Performance Software 3.5. As part of this release, Wonderware is also providing software migration tools and commercial upgrade paths to customers who have used previous Wonderware OEE offerings such as DT Analyst and Equipment Performance Module.”

Expanded performance

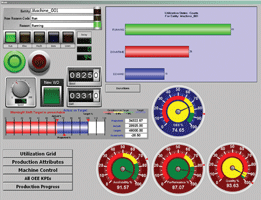

As part of Performance Software 3.5, Wonderware includes a new Utilisation Capability Object which leverages the scalability and extensibility of the Wonderware System Platform. Complete equipment monitoring strategies can be configured using this application object, which can then be rapidly deployed in multiple instances for new applications. Monitoring strategies can be easily standardised to enable effective line comparisons. In addition, system development costs are minimised due to significant reuse of applications engineering.

Furthermore, new ArchestrA graphic templates developed for downtime, OEE and production help reduce system development and enable complete customisation of KPI (Key Performance Indicator) graphic displays within the InTouch 10.0 HMI (human-machine interface) environment. These ArchestrA graphics can be easily deployed to existing InTouch 10.0 applications, allowing expanded visibility into realtime equipment performance.

New controls

Enhanced .NET controls are also built into Performance Software 3.5 to provide operators with a fully interactive display capability. Using these controls, operators can gain insight into realtime equipment performance and provide structured feedback concerning specific equipment events, enhancing the value of the system and increasing operator knowledge. In addition, extensive data filtering capabilities reduce confusion and help ensure that operators are only seeing the information they need to drive improved asset utilisation.

Timely reporting of equipment downtime and efficiency performance is done using the Wonderware Information Server component of the Wonderware System Platform. The Information Server software provides Web-based reporting and data visualisation and extends the development of report templates based on Microsoft SQL Server 2005 Reporting Services. This functionality saves time when creating and distributing equipment performance reports.

“Tight integration with the Wonderware System Platform enables us to take advantage of System Platform’s core strengths including developing functionality in a modular fashion and rolling out solutions in a controlled, repeatable manner,” said Robert Peters, chief executive officer at ASECO Integrated Systems, a Wonderware Certified Systems Integration Partner. “The new functionality has reduced the engineering effort required for ASECO to develop performance management solutions and simplifies maintenance and support for our customers. We see the combination of Wonderware Performance Software 3.5 and System Platform as hitting the sweet spot between realtime performance metrics and manufacturing intelligence.”

For more information contact Deon van Aardt, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved