Siemens automation technology has helped develop and transform industrial production for the last 50 years.

Traditionally the demands on the availability of plants and the traceability of all processes have been much greater in the process industry than in most production plants. As the requirements continue to converge ever more rapidly, much can be learned from process automation applications, where Simatic PCS 7 together with options such as plant asset management for intelligent maintenance has already achieved positive results.

One of the keynote speakers at the upcoming Siemens industry sector Totally Integrated Automation (TIA) user forum is Heinz Eisenbeiss, director of marketing and promotion for Siemens Industrial Automation Systems in Nuremberg, Germany, who will be focusing his presentation around the theme of the conference: ‘Minimise complexity, increase productivity’.

“The convenience of having necessary information for trouble-free plant operation displayed and having all interventions documented reliably later cannot remain restricted to process automation. In addition to the actual processes, so-called inbound and outbound processes are also encountered that are similar to those in the production industry: supplying raw materials, packing and warehouse logistics. For this reason, it is helpful to standardise not only the automation itself but also maintenance and process optimisation.”

Supporting maintenance with automation technology

Citing the Simatic Maintenance Station as an example, Eisenbeiss says supporting effective maintenance by automation technology begins with field devices that are capable of diagnosis and continues with the entry and evaluation of application-oriented parameters such as the availability of a complete machine or a production line.

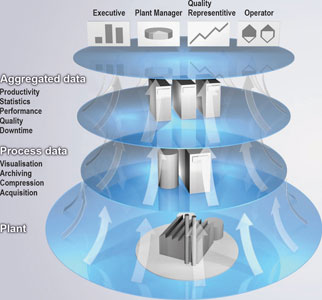

“WinCC is an ideal central entry and evaluation station for machine and process data. Options for process optimisation and quality analysis by machine data management are the WinCC/DowntimeMonitor and the WinCC/ProcessMonitor. The extension of Web functionality is also new, as seen by the WinCC/DataMonitor that allows a direct installation-free view of WinCC data over the Internet.”

While the emphasis on key performance indicators provides an economic management view of the plant, Eisenbeiss says that in the Maintenance Station this is shown from a technical point of view.

“In light of the trend toward more value-oriented maintenance these two aspects are becoming inseparable. Failure avoidance, minimised repair times and transparent failure statistics are all important pieces of information for the business manager,” he says.

For maintenance, Siemens systems automatically provide recommendations pertaining to the preventive or corrective measures required to keep plant availability high. For maximum productivity in plant operation the information processing of WinCC plant intelligence can be supplemented by the intelligent functions of the Simatic IT manufacturing execution system (MES). Production control systems can then respond to plant information without human intervention.

“Siemens is the first supplier to offer such a scalable solution spanning visualisation and MES; an automation solution that can grow with the requirements of customers who gradually optimise their production with minimal complexity and manageable costs.”

Fifty years of SIMATIC

Automation technology from Siemens has helped develop and transform industrial production for the last 50 years. From the 1950s mechanisation age that saw Simatic become a registered trademark, to changes in industrial production in the 1970s that saw the programmable logic controller (PLC) proving increasingly popular. At the 1979 Hanover Fair the Simatic S5 PLC was first shown; later establishing itself in almost every industry. Monitors and graphically programmed control engineering soon followed, and the launch of distributed I/Os in 1993 saw Profibus become a recognised standard.

Totally Integrated Automation

In 1996, Siemens unveiled Totally Integrated Automation, ensuring horizontal integration from inbound logistics to the production chain and to outbound logistics and vertical integration across all levels of the automation pyramid. Siemens also based the Simatic PCS 7 process control system on standard components from the Simatic portfolio. Increasing electronic miniaturisation allowed greater functionality in increasingly compact devices, with distributed I/Os equipped with their own intelligence.

Bridging production and management systems

2000 marked industry standard one-piece batch size production. Even cars or computers could be built to individual specifications in the automated production process, with flexible lines enabling faster product launches. Effective production requires that machines, employees and processes must be coordinated and synchronised, and in 2002 Siemens launched its Simatic IT MES in compliance with the ISA-95 MES specification standard.

The digital factory

Today, production involves coordinating production sites across countries and continents. To reduce time to market, manufacturers can set up and test new lines, virtually, in a digital factory that allows simulation and modelling of all processes – from material logistics to concrete production steps. Still driving innovation 50 years on, at the 2008 Hannover Fair Siemens showcased Simatic with Profinet, Embedded Automation and Safety as well as the new version 3.0 of the Automation Designer, an engineering solution for the digital factory.

For more information contact Keshin Govender, Siemens Southern Africa, +27 (0)11 652 2412, [email protected], www.siemens.co.za

| Tel: | +27 11 652 2000 |

| Email: | [email protected] |

| www: | www.siemens.co.za |

| Articles: | More information and articles about Siemens South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved