Background

The Motor Challenge Programme (The Programme) was launched by the European Commission in 2003 to aid industrial companies in improving the energy efficiency of their electric motor driven systems, which account for up to 30% of all electricity used in the European Union (EU). Practical experiences have shown that savings of between 30% and 50% are achievable on pump, compressor and fan systems through the use of energy-efficient design and selection methods.

The voluntary programme was developed to help to achieve the EU energy policy which aims to:

* Minimise environmental impact - in particular reduce CO2 emissions.

* Improve industry competitiveness of the trade bloc.

* Reduce dependence on imported energy sources.

Savings

Some examples quoted in the Programme's documentation show paybacks in the order of three to four months.

As at December 2007 there are 78 Motor Challenge Partners, with 34 having joined during 2007. The measures adopted by these new Motor Challenge partners in their projects have already resulted in annual electricity savings of more than 30 GWh.

Modules

The Programme issues guidelines in the form of modules to help partners document the status quo, establish project goals and record project outcomes. The modules also provide pointers in terms of where to look for potential savings.

The Drives Module is one such module. This requires challenge participants ('Partners') to:

* Inventory existing drive systems and components and system operation.

* Assess the applicability of possible energy savings methods.

* Present an action plan to the commission.

* Provide an annual report on progress of the action plan.

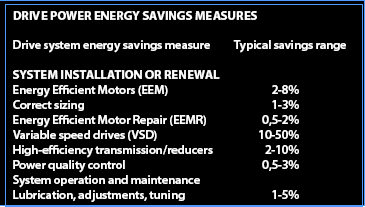

The Drives Module lists the following as factors influencing drive systems electricity consumption and shows the realisable energy savings potential of each. See Table 1.

Energy efficient motors

Energy efficient motors (EEMs), which are also called high efficiency motors (HEMs), offer 2%-6% better efficiency than standard motors and their use has many positive consequences including increased reliability, reduced downtime and improved power factor.

To help designers select appropriate drive components the European Commission:

Joint Research Centre (JRC) has developed a European motor system database, called EuroDEEM (EEM - energy efficient motors). This has data on more than 7200 motors from 29 major motor suppliers. A downloadable software tool allows users to select the most energy-efficient electric motor for a new installation or for a replacement, evaluating energy and financial savings.

Variable speed drives

When loads vary, the application of VSDs is beneficial. Based on a variety of case studies (VSDs for Electric Motor Systems: Aníbal T. De Almeida et al) a 35% average savings for pumps and fans and 15% average savings for compressors (air compressors, airconditioning and refrigeration), conveyors and other motors are achievable by using VSDs in place of fixed speed motors.

Andrew Ashton, editor, Motion Control Southern Africa

| Tel: | +27 11 543 5800 |

| Email: | [email protected] |

| www: | www.technews.co.za |

| Articles: | More information and articles about Technews Publishing (SA Instrumentation & Control) |

© Technews Publishing (Pty) Ltd | All Rights Reserved