The world faces a technical skills shortage: particularly in the engineering area. Smaller engineering teams have to look after industrial automation solutions that are increasing in scale and complexity. One of the ways to improve the effectiveness of these teams is through the use of ‘Application Standards’ based on object-oriented technology.

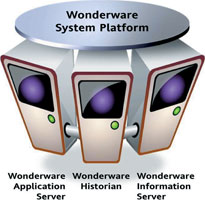

The real cost of scada applications is not the software licences but the application and the engineering hours required to generate a working solution. Wonderware's recently-released System Platform 3.0 allows object-orientated application development that provides a solution that is flexible, scalable, robust and secure. The system embraces the concept of application standards to reduce the total cost of ownership and increase the benefit of the application over its lifespan.

Object-oriented technology

Wonderware solutions such as InTouch 10.0 and System Platform 3.0 have been developed using object-oriented technology (OO). End-users of computer-based systems notice the effects of OO in the form of increasingly easy-to-use software applications.

The beauty of this approach is that when building an application, a standard template object is defined that can be used to create many standalone instances (for example the many pumps and valves on a mining project). With the latest release these standard templates include the symbol graphics and pop-ups. Templates can be grouped to create more complex objects such as a complete mill.

When commissioning and making changes to how devices behave and look, one no longer has to work with the hundreds of individual devices; changes are made once centrally and remote devices can be updated with these changes. This means that if an organisation wants to change the way in which all devices indicate bad communications, this can be achieved in a matter of minutes no matter how large or distributed the solution.

This differs from the static template-driven approach of traditional solutions. Such legacy systems offer a project approach to development, deployment and maintainability that only marginally decreases the cost and effort from site to site or from project to project. Using templates which do not fully exploit the benefits of OO can be likened to using a cookie cutter - a cookie cutter can be used to create many identical cookies but changing the cutter does not influence the cookies that have already been cut.

Object-oriented technology cannot be 'nailed on' to an application after the fact. It requires a complete redesign and rewrite of all applications and many solution suppliers prefer not to incur such massive expenses. Without OO, applications remain inflexible, expensive to maintain and even more expensive to grow.

Application standards

By application standards we mean the ability to address automation requirements using an OO (repetitive and repeatable) approach that is understood and agreed on by all team members. For example, how do engineers address the requirement for a simple valve control? What PLC code and logic should be used, which scada graphic and control interface is required? What about the alarms and statistical information?

By addressing automation requirements with well-defined standards, a company can reduce the effort and cost required to:

* Design and implement applications.

* Test, commission, support and maintain solutions.

Paper standards allow a smaller C&I team to be more effective and many good companies have used this approach. Although paper standards are a good start they are:

* Difficult to support and communicate.

* Susceptible to subtle changes and interpretation.

* Difficult to update due to the effect on existing applications.

* In need of engineering effort to implement.

A Wonderware System Platform object contains all the elements required to capture system standards, graphics, scripting, alarming, attribute extensions, historian configuration, documentation and more. Using OO an application object can become a template for driving standards within the application.

Over and above the maintainability aspect, the fundamental inheritability of OO allows new templates to be derived from existing templates. As an example, if there were three different types of valves in an application, the common elements could be defined first; after which three templates representing the variations could be derived.

In order to drive standards effectively, they must form part of the system design process. In this way, they cannot be bypassed. The application software being used for the project implementation must support standards. What is needed is a toolbox of standards that, at the scada level, includes everything needed to implement the required solution.

Looking at the above valve example, engineers should be able to simply drag the standard from their toolbox and address all the requirements listed above.

The benefits achieved with this approach are significant and include:

* Reduced engineering effort.

* Shortened commissioning time.

* More robust solution.

* Easier to change and update in future (lower cost of ownership).

Companies everywhere are realising the value of consistent information across multiple systems by creating corporate standards that are company rather than solution or hardware-specific. But once again, engineers need a platform that enables them to do this while safeguarding past investments in systems, facilitating current development and providing for future growth and versatility at minimal cost.

Wonderware's System Platform enables standards to be established and used consistently throughout an organisation, resulting in reduced training, controlled change propagation, reduced application development costs and universal understanding of how to support the application.

Application standards are also a boon for system integrators who can encapsulate and re-use intellectual property repeatedly thereby allowing them to reduce implementation costs and focus on their domain knowledge while becoming more competitive in the process. Standards also mean that rapid development is possible with smaller teams of engineers.

Conclusion

Standards are not simply an academic exercise for standards organisations. They reduce the engineering effort required for project implementations and allow smaller engineering teams to be more effective. But all this cannot happen unless there is an underlying technological infrastructure that promotes the use of standards. The new InTouch 10.0 scada solution and System Platform 3.0 from Wonderware have been specifically designed to focus engineers on the development, use and maintenance of application and industry standards.

For more information contact Justin Tweedie, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved