The myth: Variable speed drive compressors are more energy-efficient than traditional compressors that employ on/off control.

Analysis: With many industrial facilities often operating around the clock, plant-wide efficiency is paramount. The compressed air requirements on any given industrial site can be numerous and varied. Often, each application requires varying quantities of compressed air at different pressures, and at intermittent times. The resulting fluctuation in compressor load profile can complicate the task of selecting an appropriate compressor system.

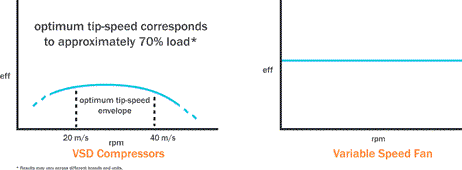

In recent years, this quest for energy efficiency has seen an increase in the use of variable speed drive (VSD) compressors. It is often - and incorrectly - assumed that a VSD will always provide a more energy-efficient means of controlling the output of an air compressor than that of an on/off motor. This misconception is born from the popular belief that a variable speed rotary screw air end displays the same performance characteristics as a variable speed fan. There is, however, a fundamental difference between the two - the efficiency of a rotary screw air end is affected by changes in the speed of the apex of the rotary screw (tip), while the efficiency of a rotating fan blade remains essentially constant, regardless of the rotational speed of the fan (see Figure 1).

This difference stands to reason, given that the rotary screw air end is a far more complex device than a simple fan. A rotary screw air end transforms the volume, temperature and pressure of incoming air, whereas a fan merely moves the air from one side of the fan blade to the other.

VSD compressors, by design, have an optimum tip speed 'envelope' within which they operate most efficiently. The optimum efficiency 'envelope' is usually bound by tip speeds of 20 m/s (at the low end) and 40 m/s (at the high end). A tip speed of less than 20 m/s results in air escaping back through the tip, while tip speeds greater than 40 m/s creates turbulent and inefficient compression.

Unfortunately, VSD compressors are designed to span the entire tip speed range corresponding to 0 to 100% compressor load. As a result, VSD compressors cannot operate within this optimum tip speed 'envelope' across the entire capacity range of the compressor. Manufacturers of VSD compressors predominantly size the air end to operate with an optimum tip speed corresponding to 70% load. When compressor loads reach above or below 85%, the tip speed is in turn adjusted above or below the optimum, and the VSD compressor's efficiency drops away.

As a result, compressors employing VSDs are more efficient than conventional on/off motor-driven compressors through approximately 50% of their capacity range - outside this '50%' envelope they are far less efficient. The manufacturer determines where this '50%' envelope lies. If the compressed air load regularly occurs outside this range, then other compressor options would be best suited to the application in place of a VSD compressor.

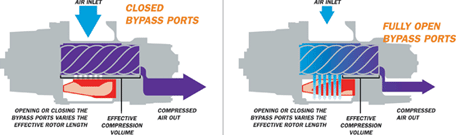

A variable output compressor (VOC) represents an ideal solution to maximising the efficiency of compressed air usage on the plant floor. The VOC is able to address changes in compressed air demand without changing the tip speed, making it one of the most energy-efficient compressed air solutions available. By controlling the delivery of air to the rotary screw air-end, the effective rotor length and compression volume is modified, enabling the delivery of compressed air at the selected capacity and pressure (see Figure 2). The VOC operates at an optimum tip speed across the entire load range (0-100%) and does not change throughout the output capacity range.

Conclusion: Before spending capital on a VSD compressor, careful analysis of the compressed air requirements of the application is crucial. It may cost more to run a VSD compressor. VSD compressors are only a more efficient compressor option in a limited number of applications. Conventional on/off load compressors are often still a more cost-effective solution.

A rotary screw air end has an optimum tip speed envelope that can be breached by a VSD. When compressor loads frequently reach levels that demand rotor speeds outside of the optimum tip speed envelop efficiency decreases and energy and money is wasted.

The ‘Compressor Myths and Truths’ series is supplied by Champion Compressors, an Australian-based designer and manufacturer of industrial rotary screw air compressors especially designed for harsh environments.

© Technews Publishing (Pty) Ltd | All Rights Reserved