Following the 27 June official announcement by GE Fanuc Automation of the USA launch of its Proficy Process Systems, the company’s South African operation is launching this system locally.

The new fully-integrated system is based on GE Fanuc's proven, award-winning process control technologies and builds on the established hardware and software products that the company has been selling as component parts.

"GE Fanuc has been a leading provider of solutions to the process industries for more than 20 years," says Daniel Coetzee, manager, Africa, for GE Fanuc Automation. "Our expertise in serving these companies has led us to this state-of-the-art system that will help to optimise operational performance, gain operational visibility, and maximise up-time and productivity."

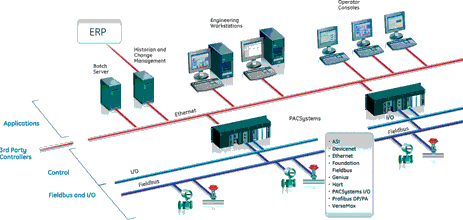

The foundation of Proficy Process Systems is a contemporary hardware and software infrastructure that offers the benefits of both traditional DCS and PLC/HMI systems, without many of the historic limitations associated with these approaches.

GE Fanuc Automation's PACSystems controllers can handle process, discrete and motion control applications, giving users control system flexibility.

Proficy software technologies provide users with process visibility, analytics, and connectivity across their organisations. The HMI/scada and Historian technologies, coupled with Batch and a complete Production Management suite, allow customers to close the gap between automation and information.

"Companies in hybrid and continuous-process industries face unprecedented pressures to perform, amidst the growing challenges of global competition, ageing technologies and increased regulatory pressures," Coetzee comments.

Scalable architecture

The architecture of Proficy Process Systems is highly scalable in terms of both system size and functionality. This allows users to cost-effectively implement applications. The system's Engineering Workstation provides an integrated development environment that centralises project engineering, including control strategies, alarm and I/O configuration, process graphics development, historian configuration and system change management.

Global namespace

The system features a common global namespace capability to provide simplified configuration and maintenance for the user. Based on technology co-developed with the GE Turbines business, tags in the system are defined once and then referenced and used commonly throughout the system, reducing system configuration time by up to 30%.

Redundancy

The broadcasting technology used by the global namespace between the controllers and Operator Consoles provides for inherent system redundancy. By leveraging advanced reflective memory know-how from the GE Fanuc Automation Embedded Systems Business, Proficy provides a controller redundancy solution with data synchronisation rates of 2 gigabits per second.

Networking and communications

The new system offers an open fieldbus approach by supporting Foundation Fieldbus, Profibus DP and PA, HART, Ethernet, and ASI. To achieve this, GE Fanuc Automation has partnered with industry-leading networking technology companies such as Softing Technologies and Pepperl & Fuchs.

Proficy Process Systems will use Softing Technologies, a recognised industry expert in Foundation Fieldbus communications, for customers who chose Foundation Fieldbus for their system, while Pepperl & Fuchs will provide Profibus connectivity and interface components for creating connections in industrial automation systems, including Profibus-based analog signal transfer and digital fieldbus communication.

System communications will be optimised by the use of powerful, high-performance, cost-effective Ethernet switch technology and products from Allied-Telesis.

Software and control

The system incorporates powerful control features, including a comprehensive set of function blocks for advanced regulatory control. User-defined function blocks create freedom and flexibility to define control algorithms as necessary, and system integrators can lock these blocks to protect intellectual property.

GE Fanuc Automation has teamed with ControlSoft to provide their 'INTUNE' product for loop tuning and optimisation. Advanced process control is available through GE Energy's KN3 model predictive control product.

For more information contact Daniel Coetzee, GE Fanuc Automation, +27 (0)31 583 3640, [email protected], www.gefanuc.com/process

© Technews Publishing (Pty) Ltd | All Rights Reserved