The modern mine manager is under increasing pressure to deliver production effectively and efficiently. Vizmine has been designed to provide accurate supporting information in this high pressure environment by delivering realtime and historical reports and analysis tools to support the challenging task of mine management.

South African software development company Adroit Technologies, in conjunction with mining consulting firm Polysphere, recently announced the release of mine management portal Vizmine.

This product, which has been designed by people with a deep level of understanding of the complexities and challenges of the day-to-day running of a mining operation, has been built on top of standard software tools supplied by Adroit.

The front-end, or user interface, is built on the Viznet information portal framework whilst the reporting engine is the Opus web reporting product. The back-end intelligence and mine management smarts reside on a Microsoft (MS) SQL database designed and engineered by Polysphere.

Simon Grimbeek, project manager from Polysphere fills in the history: "Polysphere was approached to deliver standardised daily reports to the operational management of a platinum customer. Multiple Excel spreadsheets were the standard way of capturing operational data that was ultimately rolled up into a daily report. The challenge we saw was that there are excellent planning, scheduling and scada (supervisory control and data acquisition) systems on the mines, but very little structure and business process to deliver feedback regarding the mine's performance on a realtime progressive basis and against total plan."

Grimbeek continues: "Data integrity and timing are always challenges and more importantly finding where the bottlenecks exist. Identifying where exceptions exist in the execution of a mining plan is complex. Vizmine ensures data integrity and timeous capture through intelligent, yet easy to use, interfaces."

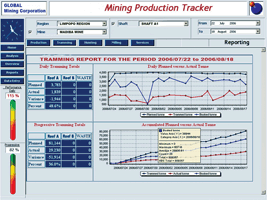

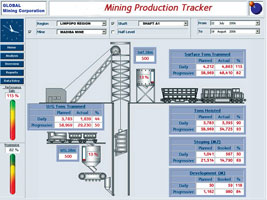

Vizmine has been designed to provide a one-stop information shop for the modern mining manager where actual daily or periodic production data is analysed against the mine's plan or key performance indicators (KPIs) as determined by the production team. The system gives an ore (and waste) balance for the entire mining process from the time that ore leaves the stope up to delivery to the mill, with the added ability to track problems along this process route.

Raf Bryla, managing director of Polysphere adds: "We initially looked at building a standalone system built on MS Access but soon realised that the main value was going to be in the business intelligence aspects of the reporting. In order to achieve this, a more scalable platform was required and so we chose MS SQL. The next challenge was to get appropriate operational data from various systems on the mine. After doing some investigations we chose the Viznet portal technology and the Opus web reporting software from Adroit Technologies."

Adroit's business development manager, Malcolm Heathfield says, "Viznet gave us everything we needed, an off-the-shelf portal framework that supported secure access to standard databases, OPC (OLE for process control) for realtime data and a scalable client-server architecture. We soon realised that combining this with the integration capabilities in Opus would allow us to rapidly build a product without the risks of a customised solution."

The entire Vizmine system is Internet enabled, making data capture, reporting and analysis screens easily and widely available in realtime, across a mining operation. Analysis can be carried out across selected time frames and/or at different levels within the operational structure, enhancing management's ability to drill down into the mine's production data.

Minute-by-minute, realtime monitoring of underground tonnes trammed, tonnes hoisted or tonnes to mill can be provided to mine management. By linking this type of data to a mine's existing planning and scheduling software, an analysis of actual versus target performance can be done and linked to a dashboard for executive feedback.

Dave Wibberley, managing director of Adroit Technologies concludes, "Opus and Viznet were a perfect fit for Polysphere's needs and we believe that the cost of the products far outweighs the risks and challenges that Polysphere would have faced if they had chosen to build a proprietary system. We estimate that integration of our various products as opposed to developing them saved between 50% and 75% of the time that would otherwise have been required.

"A lot of major suppliers have been battling to deliver the same solution for more than two years. We managed to deliver a functional prototype for a proof of concept within two months! Further savings will be realised as more functionality is added to the system.

"The off-the-shelf software capability of Opus allows for easy system customisation. It is this same ease-of-use in Vizmine that makes us confident that it will become the reporting standard on many of our deep level mines in the future."

For more information contact Dave Wibberley, Adroit Technologies, +27 (0)11 658 8100, [email protected], www.adroit.co.za

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved