In the planning as well as in the construction of machines or plants, it helps to solve automation tasks quickly and efficiently. In order to fulfil these requirements, the adaptability of the automation system should play a decisive role. The solution should not have to adapt itself to a system, but rather the system to the solution. Even if the automation requirements are different, they should all have a common goal: to obtain the utmost success but be as cost effective as possible. The I/O grouping (signal count) and functionality per module always plays a big role in the decision making of a specific type (modular or block) of remote I/O system.

Fieldbus openness and decentralization

The use of remote I/O creates a big cost reduction in comparison with the use of old conventional parallel wiring systems. It is very important that all fieldbus systems can connect to existing field instruments and fieldbus openness is also an important requirement for an automation system. Through fieldbus systems, further possibilities open themselves with suitable installation systems for yet more efficient automation solutions. Example: by using decentralised switchgear in small cabinets next to the relevant machine, it will do away with the central switchgear building and in the process save a lot of money on the reduced wiring.

I/O-components

The protocol independence as well as the possibility to have the I/O decentralised (next to the machine) does not close the automation loop completely. Different types of signals and very complex functions need to be connected via the fieldbus system and to do that you will need different types of modules. The different modules start from simple digital functionality to very complex serial protocol modules (example RS485), encoder, pulse and PID controllers. The specific module receives the information from the field instrument, converts it into the specific protocol and then transmits the data via the protocol to the PLC/DCS master.

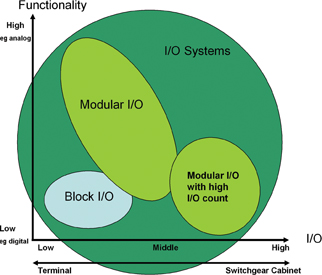

I/O can be split into two different types:

* Block I/O

This is a very compact solution; block I/O has all the functionality needed to connect sensors and actuators to a fieldbus system. It is a standard configuration and it is not possible to change the I/O count.

* Modular I/O

Modular I/O creates the possibility to configure any type of local bus. By going this way you have the possibility to change the protocol as well as the number of I/O and functionality. All the connections (power and data) happen internally and therefore the wiring expense can be reduced even more.

Modular or compact?

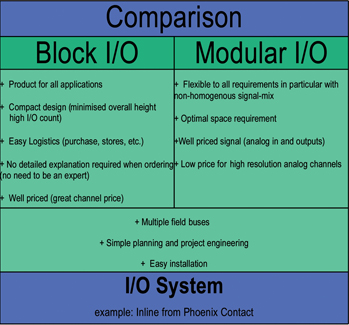

The question still remains which automation solution is the best? Block I/Os or modular I/Os.

Remote I/O can be split into two categories:

* Direct connection of sensor/actuator signals in the field through multiple bus connections with peripheral diagnostics.

* Advance/complex control signal with multiple bus connections.

The product family block I/O of Phoenix Contact offers multiple bus connections as well as peripheral diagnostics. It is very important when using block I/O, to have the right I/O count. Furthermore the signal distribution in the plant is of high importance. Investigations have shown that the average number of inputs/outputs of a station lies between 16 and 64 channels. The signal split is as follows:

* 52% digital inputs.

* 40% digital outputs.

* 6% analog signals.

* 2% other functions.

In this regard the block I/O is ideal.

Modular and compact!

There are, however, often cases that do not conform to a typical situation. Possibly there is a need for a few or even many more I/O channels, or there is a mix of analog/digital/other functions in the same I/O station. Here the use of a modular system is an advantage. Thereby, the necessary functions and channels can be arranged optimally and cost-effectively.

In addition, there might be situations where a mixture of modular and block I/O represents the most efficient and/or cost-effective solution. Thanks to the inter-connectivity of modular and block I/O, the optimal solution can be found.

Both modular and block I/O offer their own advantages. With a combination of both technologies one brings a good price versus performance ratio for each task of automation (Figure 1). This shows the Inline I/O system of Phoenix Contact. This system offers modular I/O terminals with different density as well as different functions. In addition, there is now also compact Inline Block I/O. With the same onboard diagnostics and the same connection technology, they fit seamlessly into the Inline product range and expand upon the principle of multiple, open bus systems with cost-optimised, fixed digital I/O configurations.

Ergonomics of the Inline Block I/O system

The use of Inline Block I/O modules offers ergonomic advantages from the installation phase through to maintenance. It begins with a simple assembly as well as disassembly, requiring as few tools as possible. The design also offers DIN rail mounting connection as standard.

The next step is the electrical connection of the module. The Inline I/O system offers intuitive, easy connection. Standardised bus connections and peripheral connections are employed. The terminal points are easy to reach and very little space is required in order to operate them. A self-evident inscription of the connections is provided on the terminal connector strips.

The system is tolerant of installation mistakes, by making it easier for the installer as well as being protective of the module. Also, the link to the control system is simple and standardised. During operation, the onboard diagnostics are easy to see as they are not concealed from view and are easily recognisable.

As a result of all these features, the Inline Block I/O system allows for short installation and maintenance times.

Summary

The compact Inline Block I/O from Phoenix Contact is suitable for digital inputs and outputs and allows for a high degree of decentralisation. The combination of modular with block I/O is even more efficient and provides for an even larger number of possibilities. In the inline installation system, both I/O types are simultaneously applicable. This allows for the user to maximise the respective advantages and strengths of both I/O types to provide the optimal solution (Figure 2). The extensive product range of the Inline system makes different applications possible in the cabinet or in the field.

| Tel: | +27 11 801 8200 |

| Email: | [email protected] |

| www: | www.phoenixcontact.co.za |

| Articles: | More information and articles about Phoenix Contact |

© Technews Publishing (Pty) Ltd | All Rights Reserved