Wonderware has announced the introduction of new industrial automation and MES solutions based on its ArchestrA architecture designed to streamline production and performance management.

In order to better map its extensive range of software solutions to the real needs of end-users, Wonderware has introduced a number of new packages that address system infrastructure, supervisory functionality, equipment management and manufacturing execution.

"This approach is more real to end-users because these are the blocks of functions they have to deal with every day," says Justin Tweedie, MD of Wonderware Southern Africa (formerly Futuristix), a member of the EOH group of companies. "Now, system integrators and end-users no longer need to concern themselves with the details of individual components but can rather focus on the functionality they need in order to achieve a higher level of production and performance management."

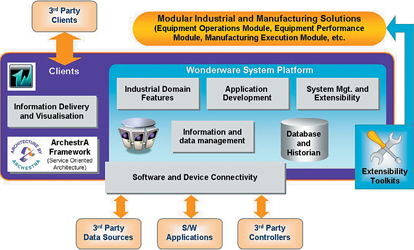

System Platform

This package provides the basic system infrastructure and includes the Wonderware Application Server, the Wonderware Historian, the Wonderware Information Server, the Wonderware Device Integration Server and a selection of Wonderware Client Products. One of these client packages is the new Supervisory Client, which consists of an HMI View Client (InTouch) and trending analysis tool (ActiveFactory).

The value of the Wonderware System Platform for manufacturing applications includes:

* Achieving operational excellence without abandoning prior investments in automation systems, production processes or intellectual property through an industry standards-based, open environment that provides unsurpassed connectivity and integration capabilities.

* Adding and growing as necessary through a sustainable manufacturing operations systems platform with complete scalability.

* Unifying diverse automation systems for improved operations and information management.

* The ability to design, build, secure, standardise, maintain and deploy plant intelligence applications.

* Driving corporate standards to replicate success across the enterprise and reducing engineering costs.

* Lowering lifecycle costs for plant IT solutions.

* Changing and expanding the system as a whole without disruption to running plants.

* Enterprise-wide integration across multiple, geographically distributed plants.

"The Wonderware System Platform can be compared to a computer's operating system," adds Tweedie. "It is the backbone and facilitator for all production and performance management software initiatives."

Equipment Operations Module

The Equipment Operations Module incorporates the functionality of the Production Events Module and the new Formula Management Module. It is designed to help manufacturers:

* Improve brand integrity by consistent execution of unit/line operations, setups and raw material usage.

* Fulfil regulatory requirements through complete 'as-built' records, enabling rapid and economical response to unforeseen production events such as product recalls.

* Improve time-to-volume and responsiveness through improved reliability and repeatability of equipment setup and operations with immediate detection of deviations from specifications and re-use of encapsulated best practices.

* Reduce cost of integration through the use of standard structures for 'product definition' and 'production actuals' according to the ISA-95 standard for enterprise to control system integration.

Some of the functional capabilities of the Equipment Operations Module are:

* Automatic recording of realtime production events into a database, including a log of set points downloaded to the equipment.

* Providing production context to the process, formula and event data using a standard structure (ISA-95).

* Creating traceability across production processes, production areas and different systems.

* Managing equipment product formula settings downloaded to the control system and equipment procedural enforcement capability for operators at runtime.

* Enabling analysis and reporting of product and production history, including full genealogy.

* Enabling easy feedback to production management and ERP on production actuals in realtime.

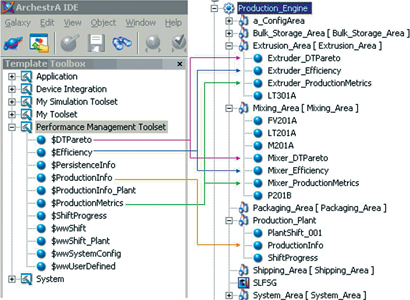

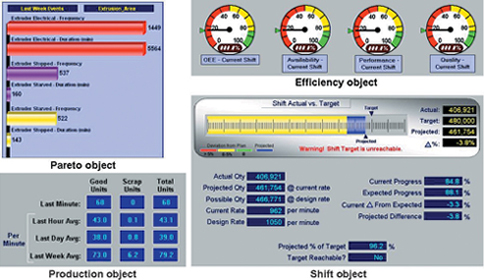

Equipment Performance Module

The Equipment Performance Module is a combination of the functional capabilities found in the existing DT (DownTime) Analyst product integrated with application objects running on the Wonderware System Platform shown in Figure 1. The Equipment Performance Module helps manufacturers:

* Reduce capital expenditure by identifying the most productive assets for continued operation.

* Increase the capacity of existing assets by identifying the causes of unplanned downtime and improved operator involvement.

* Reduce time-to-market by identifying production bottlenecks more quickly and increasing supplier accountability during plant or production line start-up.

* Rapidly determine and display actual key performance indicators (KPIs) against targets.

* Determine actual equipment performance in realtime.

Figure 2 shows the deployment of some of the Equipment Performance Module's objects to a live plant. These are inserted under any line, area or machine of the plant model and start to generate useful data immediately because they are intelligent and self configuring - the instance knows how to connect to its data source and its context (for example the Extrusion Area). The gathered information is then used in the display of plant dashboards and KPIs.

Manufacturing Execution Module

The Manufacturing Execution Module is a new version of InTrack and uses Internet Explorer for viewing documents instead of the Doc Viewer. The manufacturing execution module includes support for SQL Server 2005 and Oracle 10g as well as the latest operating system platforms.

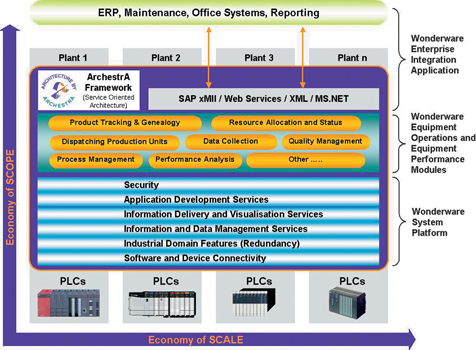

Putting it all together

"By basing solutions on a versatile infrastructure like ArchestrA and grouping them such that they are aligned towards meeting the operational and business objectives of companies, new levels of productivity and flexibility can be achieved," says Tweedie.

"An economy of scale is realised through the ability to extend common platform functionality, engineering standards and information across as many plants as needed (see Figure 4). All the plants are treated as a single 'virtual' plant. This means that system expansion or modification is done at the click of a button rather than having to re-invent an expensive wheel for every project - and it can all be done by using existing assets.

"An economy of scope is also realised because of the interoperability of applications from shop floor to top floor. The ISA-95 standard and the cooperation between companies at either end of the application spectrum (eg, SAP and Wonderware), has led to an increasingly seamless integration of business, production and manufacturing functions. This, in turn, has led to the concurrent viewing of manufacturing and business information on meaningful, realtime dashboards that allow for tighter control of cause and effect scenarios and a healthier bottom line."

QuickStarts

The new modules include one or more QuickStarts. A QuickStart consists of a pre-configured example of best practices to address a specific manufacturing scenario. QuickStarts accelerate the design and implementation by supplying example applications, database structure, HMI graphics, web reports and implementation guidelines. Wonderware software is renowned for its ease of use and the combination of the System Platform, software modules and QuickStarts are intended to dramatically simplify and modularise the way in which customers approach software solutions.

For more information contact Justin Tweedie, Wonderware Southern Africa (a member of the EOH Group of Companies), +27 (0)861 WONDER (+27 (0)861 966 337), [email protected] or [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved