ZF Lemförder South Africa, with its head office in Rosslyn, is a global player in the production of sub-components for motor vehicle manufacturers around the world. ZF Lemförder produces the front and rear axles for the BMW 3 series sedan, which is produced at BMW's South Africa plant, also based in Rosslyn. The manufacturer's production lines and custom built machines are equipped with Beckhoff technology.

BMW operates according to a build plan, and an intelligent forecasting mechanism allows it to order the exact required axles from ZF Lemförder 310 minutes ahead of when they are needed for fitment. Every axle requested joins the queue of axles to be built. The call off not only provides a unique identification number and model detail, but also links to an entire database containing exact part and build requirements for each variant of axle.

The assembly lines for the front and rear axles of the BMW 3 series E90 model were conceptualised, designed, installed and commissioned by Jendamark Automation, system integrator for Beckhoff products in South Africa. Jendamark first built production lines and custom built machines for ZF Lemförder in 1998. These production facilities were used to produce the differentials as well as front and rear axles for the BMW E46 series. Since then, the two companies have been co-operating continuously. Jendamark Automation also provided the axle production lines for ZF Lemförder in China, building the BMW E90 and E60 series axles.

Process of operation

The transport of all axles on the production line occurs by means of AGVs (automated guided vehicles). When an empty AGV stops at the start of the production line, the RFID (radio frequency identification device) of that specific AGV is linked to a particular axle in the database. At this point, the production of a new axle is started, and the axle's position in the database will be continuously updated through means of the RFID tracking at each station.

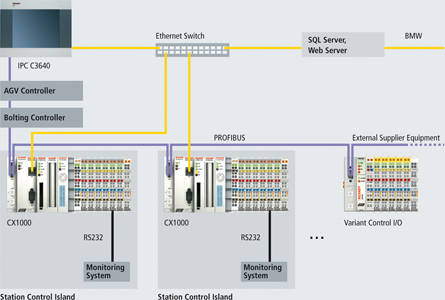

Each station is controlled by a Beckhoff CX1000 with Windows XP embedded as operating system and TwinCAT realtime PLC. This allows all the I/Os of this station to be controlled locally, while Ethernet and PROFIBUS Fieldbus systems allow for interaction between the control system and the rest of the production facility. (See system configuration diagram.) All the Beckhoff Bus Terminals connect directly to the CX1000 and provide I/O capabilities for digital, analog, serial as well as loadcell and position measurement signals. The TwinCAT PLC on the CX1000 interacts with a station control application (developed in Microsoft Visual Basic), which acts as front end user interface to the station's operation.

Production monitoring via SQL server

As a new part enters the station on the AGV, the RFID identifies the specific axle. The station control application retrieves all required variant and building instructions from the SQL server. Variant specific screens indicate to the operator how to proceed with the assembly, and variant lamp indicators assist them in using the correct parts for the build. According to the variant requirement, the bolting, camera inspection and assembly procedure is adapted by the station control, and the onscreen representation of the process is displayed. In addition to selecting the correct bolting parameters from the SQL server, the actual position of the bolting tools are being monitored by means of ultrasonic sensors in each station to further ensure correct operating procedures. All results gathered from the assembly process are first logged to the SQL server and then verified against the predefined specifications.

Straightforward integration into the company network

All operations are enabled by the use of an operator identification mechanism. This is utilised to ensure that the particular operator in that station has been trained sufficiently in order to safely and correctly use all equipment in that particular station. This same identification mechanism is used to allow system administrators and maintenance personnel to access restricted higher level functions on the system control. The advanced features of the station control system allow administrators to alter station specific settings. The required position of bolting tools, amount of operations, tool verification, calibration, reworks and order of axles to be built can all be administrated right from the station.

The Ethernet connectivity of the CX1000 allows for very easy integration into the standard plant network. Using Microsoft Internet Explorer, embedded in the Visual Basic station control application, the production information system completes the software component of each station. The production information system allows the operator in each station to view the exact part drawings and assembly instructions for the individual axle variant he is currently working on.

System notifications and warnings are also indicated by means of the information system.

Production system

The production facilities consist of the following items:

1. SQL server containing all forms of information

- axle build requirements.

- variant information.

- specifications.

- part drawings and assembly instructions.

- operator/maintenance/administrator security control.

2. A central C3640 Industrial PC with TwinCAT software PLC

- controlling PROFIBUS Fieldbus system for Bosch bolting tool control.

- controlling several independently operated stations.

3. 40 Beckhoff CX1000 solid state embedded PCs

- PLC controlling every station's operations.

- Windows XP embedded for front-end applications.

- PROFIBUS interface for connecting to bolting tools.

- Visual Basic user interface software.

- web browser for production information and notifications.

4. Ethernet communication backbone between all control devices and SQL server and web server.

5. Bosch bolting controllers and bolting tools.

6. AGV (Automated Guided Vehicles) acting as axle carriers.

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved