The GE Fanuc Automation division of GE Industrial, is pleased to announce the availability of CIMPLICITY Version 7.0, the latest addition to its family of HMI/SCADA products.

CIMPLICITY 7.0 helps you improve your business performance, through powerful new features and increased integration with the company's Proficy family of products. It has focused on improving security, disaster prevention and recovery, simplified project development, and improved connectivity to CNCs.

Indeed, with CIMPLICITY 7.0, your development costs will decrease, and your daily operational performance will improve.

Improving your operations and business performance

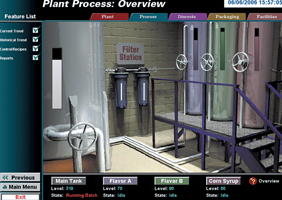

CIMPLICITY 7.0 extends the product's ability to solve the toughest supervisory monitoring and control projects. One of the key ways CIMPLICITY can help customers improve their business performance, is through the integration with other products in the Proficy family.

The features and functionality delivered by these products can have an enormous multiplying effect on the capabilities of our customer's systems. The following provides an outline of the other Proficy products, how they integrate with CIMPLICITY, and the resulting benefits they can deliver:

Change Management - have you ever wished you could revise a change you made to your project? A first to the industry, GE Fanuc Automation has integrated its Change Management product with CIMPLICITY to provide you with revision control of your projects. Now you can check out and check in files, roll back to known configuration, and track who has made what changes to the system.

The Change Management functionality also provides you with powerful disaster recovery capabilities - allowing you to restore your system to a known working point in the event of a computer failure. When you consider what downtime can cost you, this combination of Change Management and CIMPLICITY provides invaluable insurance and peace of mind.

Portal - the ability to analyse your current and historical data into meaningful information is critical to improving your operations. You can add this analytical capability to your CIMIPLICITY system with GE Fanuc's Automation's Portal product. Portal provides the ability to perform analysis on the data that your HMI/SCADA systems generate, through sophisticated charting and reporting tools.

Enhancements have been made in CIMPLICITY 7.0, that now allow you to host Portal screens within your CIMPLICITY screens; or CIMPLICITY screens within your Portal screens. You now have even further insight into your operations than ever before.

Historian - accurate data is essential as a basis for analysing how you can improve your business's performance. The ability to quickly access that data and use it strategically is what separates the successful plants from the unsuccessful ones.

CIMPLICITY 7.0 adopts the Historian product as its default logging source. When using historical trends in CIMPLICITY, Historian provides a significant performance enhancement over SQL, in many cases 10 times the increase in the speed of retrieving and charting the data. SQL is still supported, and in fact logging to both SQL and Historian at the same time is supported. This allows customers to change their logging requirements at their own pace.

Proficy View - CIMPLICITY can easily integrate with View nodes to exchange points and alarms. An enhancement was added to 7.0 to allow View array points to be mapped to CIMPLICITY array points.

Reducing development costs and improved connectivity through OPC enhancements

GE Fanuc Automation understands the importance of an open system approach to your automation. Therefore, in Version 7.0, the CIMPLICITY OPC Server is now included at no additional charge. The OPC Server allows you to provide information that CIMPLICITY has gathered or generated, to other OPC capable systems. Additional features include:

OPC Event handling - Version 7.0 adds the ability to handle OPC Events in addition to the existing capability of handling OPC Alarms.

OPC configuration enhancements - The configuration of OPC communications has been greatly enhanced, by a new OPC browsing and configuration user interface. This allows you to browse any node for a list of OPC servers installed on that node. When selecting one, the proper 'Device Address' for that OPC server is automatically entered for you.

E-mail notification - Alarm & Event Express lets you define e-mail destinations separately from source subscriptions. Define all the possible recipients for e-mail, complete with a weekly schedule of availability, then define subscriptions to Alarm and Event messages.

As a message is detected, Alarm & Event Express will create an e-mail message, following the user configured formatting, and send it to one or more e-mail recipients. Alarm & Event Express can send e-mails to one or more destinations. Each e-mail destination offers a weekly schedule with hour level time resolution.

The schedule controls e-mail address validity throughout the week. Finally, e-mail messages can include a subject and attachments. Typical uses include highlighting the purpose of the e-mail in the subject and attaching a report of additional information, or attaching a document that defines alarm or event management procedures.

Improved security

Today, security is more important than ever. With CIMPLICITY 7.0 security on several levels have been addressed, as outlined below:

Integration with Change Management - allows you to control access to who can make changes to a project. In addition, you can track changes made to your projects, knowing who, what, and when the changes were made. You then have the ability to back up and restore your projects. This allows you to roll back a configuration change to a previous point - and allows you to implement an effective disaster recovery plan.

Project Start/Stop security - it is now possible to specify that a password must be entered before a project can be started or stopped. This prevents the inadvertent starting or stopping of a project and the resulting consequences.

Privileges for right mouse menu actions - you can now configure whether the user can bring up the right mouse menu in Point Control Panel, Alarm Viewer control, and CimView. You can also control if the Quick Trend or Point Control Panel items are displayed on the menu.

Password enhancements - for customers in regulated industries, or for anyone wishing to increase the security of their passwords, Version 7.0 has been enhanced to allow the requirement for passwords to have a minimum of six characters.

Take action off of alarms

The CIMPLICITY Alarm Viewer allows you to easily consolidate, view and take action on alarms that are generated in your system. The CIMPLICITY Alarm Viewer has been enhanced to allow events to be triggered off selected alarms. This new event will return the Point ID as well as the button of mouse having generated the click (left click or right click). This new event can then be used within scripts to initiate user-defined actions.

Improved CNC connectivity

For customers using Fanuc CNCs, support for new controllers and added Tool Life Management features have been added.

Support for New Controllers Series - the HMI for CNC option has been enhanced to support the 160iB, 180iB, 210iB, and Series 0i Model B controllers.

Tool Life Management - Tool Management support has been created for the Series 300iA, 310iA and 320iA controllers to provide full Tool Life Management functionality.

Proficy Plant Applications - cornerstone of realtime production management

For years, manufacturers throughout the world have recognised the critical link between production efficiency and profitability. The demand for speed, agility and responsiveness in your production operations has never been greater - transforming not only how you manage production assets, but how you do business. As a result, realtime production management is now a cornerstone of any profitable company. And in turn, Proficy Plant Applications is the cornerstone of realtime production management.

Proficy is an open, powerful and intelligent production solution, that provides the plant automation, analysis and execution capabilities that every manufacturer needs.

Proficy Plant Applications are designed to leverage the powerful technology of Historian applications, allowing you to capture far more production data than traditional MES tools - and includes configurable software packages designed for a rapid return on existing technology investments.

These applications include:

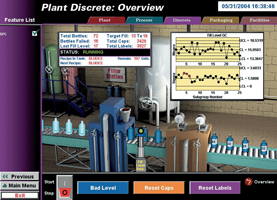

* Efficiency - tracking and monitoring of OEE (downtime, waste, production counts).

* Quality - product and process quality analysis and control.

* Production - production schedule execution and product genealogy tracking and reporting.

* Batch analysis - batch trending, analysis and reporting.

* Plant-wide Web reporting - integrated scheduled and ad-hoc web reporting across all modules.

CIMPLICITY - 'simply' the best choice

By providing you with superior visibility into your operations, GE Fanuc empowers and enables your users to take strategic action when it is required - based on realtime information of what is happening in the process. Whether upgrading an existing system, or implementing a new project, CIMPLICITY 7.0 will provide you with the power, flexibility, and user-friendliness you need.

The implications for your success are endless.

For more information contact Daniel Coetzee, GE Fanuc Automation, +27 (0) 31 583 3640, [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved