Handling with EtherCAT is straightforward and similar to a fieldbus, thanks to flexible topology and simple configuration. Moreover, since EtherCAT can be implemented very cost-effectively, the system enables fieldbuses to be used in applications where fieldbus networking was not an option in the past. EtherCAT is an open technology for which IEC standardisation is in progress. Support is provided by the EtherCAT Technology Group, an international association of users and manufacturers with more than 380 member companies.

EtherCAT technology overcomes these inherent limitations of other Ethernet solutions: The Ethernet packet is no longer received then interpreted and process data then copied at every device. The EtherCAT slave devices read the data addressed to them while the frame passes through the node. Similarly, input data is inserted while the telegram passes through. The frames are only delayed by a few nanoseconds.

Since an Ethernet frame comprises the data of many devices both in send and receive direction, the usable data rate increases to over 90%. The full-duplex features of 100BaseTX are fully utilised, so that effective data rates of >100 Mbps (>90% of 2 x 100 Mbps) can be achieved.

The Ethernet protocol according to IEEE802.3 remains intact right up to the individual terminals; no sub-bus is required. In order to meet the requirements of the electronic terminal block, only the physical layer in the coupler is converted from twisted pair or optical fibre LVDS. LVDS is a fast and cost-effective, alternative physical Ethernet layer that can also be used for 10 Gigabit Ethernet (IEEE802.3ae). At the end of the modular device the system is simply switched back to 100BaseTX.

EtherCAT protocol

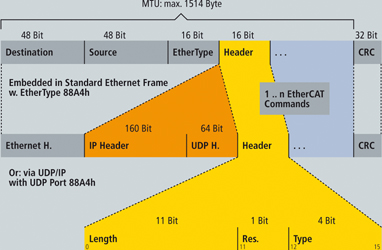

The EtherCAT protocol is optimised for process data and is transported directly within the Ethernet frame thanks to a special Ethertype. It may consist of several sub-telegrams, each serving a particular memory area of the logical process images that can be up to 4 gigabytes in size. The data sequence is independent of the physical order of the Ethernet terminals in the network; addressing can be in any order. Broadcast, multicast and communication between slaves are possible. Direct Ethernet frame transfer is used in cases where maximum performance is required and the EtherCAT components are operated in the same subnet as the controller.

However, EtherCAT applications are not limited to a subnet: EtherCAT UDP packages the EtherCAT protocol into UDP/IP datagrams (see Figure 1). This enables any control with Ethernet protocol stack to address EtherCAT systems. Even communication across routers into other subnets is possible. In this variant, system performance obviously depends on the realtime characteristics of the control and its Ethernet protocol implementation. The response times of the EtherCAT network itself are hardly restricted at all: the UDP datagram only has to be unpacked in the first station.

Topology

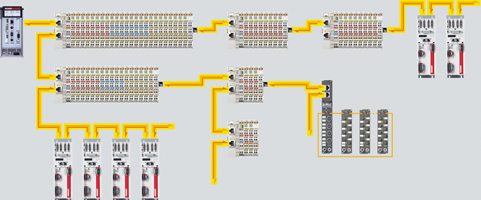

Line, tree or star: EtherCAT supports almost any topology (see Figure 2). The bus or line structure known from the fieldbuses thus also becomes available for Ethernet.

Particularly useful for system wiring is the combination of line and branches or stubs: the required interfaces exist on the couplers; no additional switches are required. Naturally, the classic switch-based Ethernet star topology can also be used. Wiring flexibility is further maximised through the choice of different cables. Flexible and very cost-effective standard Ethernet patch cables meet the 100BaseTX transfer requirements. Plastic optical fibres (POF) complement the system for special applications. The complete choice of Ethernet wiring - such as different optical fibres and copper cables - can be used in combination with switches or media converters.

The Fast Ethernet physics (100BaseTX) enables a cable length of 100 m between two devices. For each connection, the signal variant can be selected individually. Since up to 65 535 devices can be connected, the size of the network is almost unlimited.

Distributed clocks

Accurate synchronisation is particularly important in cases where spatially distributed processes require simultaneous actions. This may be the case, for example, in applications where several servo axes carry out coordinated movements simultaneously.

The most powerful approach for synchronisation is the accurate alignment of distributed clocks, as described in the new IEEE1588 standard. In contrast to fully synchronous communication, where synchronisation quality suffers immediately in the event of a communication fault, distributed aligned clocks have a high degree of tolerance vis-á-vis possible fault-related delays within the communication system.

With EtherCAT, the data exchange is fully based on a pure hardware machine. Since the communication utilises a logical (and thanks to full-duplex Fast Ethernet also physical) ring structure, the master clock can determine the propagation delay offset to the individual slave clocks simply and accurately - and vice versa. The distributed clocks are adjusted based on this value, which means that a very precise network-wide time base with a jitter of significantly less than 1 microsecond is available. External synchronisation, for example across the plant, is then based on IEEE1588.

However, high-resolution distributed clocks are not only used for synchronisation, but can also provide accurate information about the local timing of the data acquisition. For example, motion controllers typically calculate velocities from sequentially measured positions. Particularly with very short sampling times, even a small temporal jitter in the position measurement leads to large step changes in the computed velocity. With EtherCAT, timestamp data types are introduced as a logical extension. The high-resolution system time is linked to the measured value, which is made possible by the large bandwidth offered by Ethernet. The accuracy of a velocity calculation then no longer depends on the jitter of the communication system. It is orders of magnitude better than that of measuring techniques based on jitter-free communication.

Performance

EtherCAT reaches new dimensions in network performance. Thanks to hardware integration in the slave and direct memory access to the network card in the master, the complete protocol processing takes place within hardware and is thus fully independent of the run-time of protocol stacks, CPU performance or software implementation. The update time for 1000 I/O is only 30 μs - including the I/O cycle time. Up to 1486 bytes of process data can be exchanged with a single Ethernet frame - this is equivalent to almost 12 000 digital inputs and outputs. The transfer of this data quantity only takes 300 μs.

The communication with 100 servo axes only takes 100 μs. During this time, all axes are provided with command values and control data and report their actual position and status. The distributed clock technique enables the axes to be synchronised with a deviation of significantly less than 1 microsecond.

The performance of the EtherCAT technology enables control concepts that could not be realised with classic fieldbus systems. With EtherCAT, a communication technology is available that matches the superior computing capacity of modern industrial PCs. The bus system is no longer the bottleneck of the control concept. Distributed I/O is recorded faster than is possible with most local I/O interfaces. The EtherCAT technology principle is scalable and not bound to the baud rate of 100 Mbaud - extension to Gbit Ethernet is possible.

Diagnosis

Experience with fieldbus systems shows that availability and commissioning times crucially depend on the diagnostic capability. Because faults are detected quickly, accurately and located unambiguously, they can be rapidly rectified. Therefore, special attention was paid to exemplary diagnostic features during the development of EtherCAT.

During commissioning, the actual configuration of the nodes (for example drives or I/O terminals) should be checked for consistency with the specified configuration. The topology should also match the configuration. Due to the built-in topology recognition down to the individual terminals, this verification can not only take place during system start-up, but automatic 'reading in' of the network is also possible (configuration upload).

Bit faults during the transfer are reliably detected through evaluation of the CRC checksum: The 32-bit CRC polynomial has a minimum hamming distance of 4. Apart from broken wire detection and localisation, the protocol, physical layer and topology of the EtherCAT system enable individual quality monitoring of each individual transmission segment. The automatic evaluation of the associated error counters enables precise localisation of critical network sections. Gradual or changing sources of error such as EMI influences, defective connectors or cable damage are detected and located, even if they do not yet overstrain the self-healing capacity of the network.

EtherCAT instead of PCI

With increasing miniaturisation of the PC-components, the physical size of industrial PCs is increasingly determined by the number of required slots. The bandwidth of Fast Ethernet, together with the process data width of the EtherCAT communication hardware enables new directions: classic interfaces that are conventionally located in the IPC are transferred to intelligent EtherCAT interface terminals. Apart from the decentralised I/O, drives and control units, complex systems such as fieldbus masters, fast serial interfaces, gateways and other communication interfaces can be addressed.

Even further Ethernet devices without restriction on protocol variants can be connected via decentralised hub terminals. The central IPC becomes smaller and therefore more cost-effective. One Ethernet interface is sufficient for the complete communication with the periphery.

EtherCAT components from Beckhoff

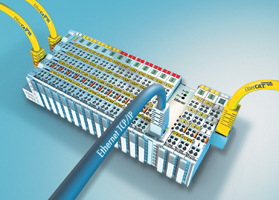

On the hardware side, EtherCAT technology is located in EtherCAT Terminals, for example. The I/O system in protection class IP20 is based on the housing of the tried and tested Beckhoff Bus Terminal system. In contrast to Bus Terminals, where the fieldbus protocol data is converted within the Bus Coupler to the internal, fieldbus-independent terminal bus, the EtherCAT protocol remains fully intact down to the individual terminal. In addition to EtherCAT Terminals with E-bus connection, the proven standard Bus Terminals with K-bus connection can also be connected via the BK1120 EtherCAT Bus Coupler. This ensures compatibility and continuity with the prevalent system. Existing and future investments are protected. The Beckhoff servo drives are also available with EtherCAT interface.

EtherCAT will be integrated in further Beckhoff components, such as the Fieldbus Box in protection class IP67. The Beckhoff Industrial PCs, the embedded PCs of the CX series, the control panels with control functionality, and the Ethernet PCI cards already offer inherent EtherCAT capability.

Summary

EtherCAT is characterised by outstanding performance, very simple wiring and openness for other protocols. EtherCAT sets new standards where conventional fieldbus systems reach their limits: 1000 I/O in 30 μs, optionally twisted pair cable or optical fibre and, thanks to Ethernet and Internet technologies, optimum vertical integration. With EtherCAT, the costly Ethernet star topology can be replaced with a simple line structure - no expensive infrastructure components are required. Optionally, EtherCAT may also be wired in the classic way using switches, in order to integrate other Ethernet devices. Where other realtime Ethernet approaches require special connections in the controller, for EtherCAT very cost-effective standard Ethernet cards (NIC) are sufficient.

EtherCAT makes Ethernet down to the I/O level technically feasible and economically sensible. Full Ethernet compatibility, Internet technologies even in very simple devices, maximum utilisation of the large bandwidth offered by Ethernet, outstanding realtime characteristics at low costs are exceptional features of this network. As a high-speed drive and I/O bus for Industrial PCs, or in combination with smaller control units, EtherCAT is expected to be widely used in a wide range of applications.

For more information contact Beckhoff Automation, +27 (0) 11 792 3372, +27 (0) 11 792 5453, [email protected], www.beckhoff.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved