Although significant value is added to the entire production line from raw material batching to final packaging, pelleting and distribution, the implementation of a supervisory control and data acquisition (scada) system is seldom undertaken as one complete project encompassing all the production phases simultaneously. For many companies, the process of upgrading to a scada system is undertaken over an extended period of time and completed in phases associated to each stage of the production process. The Rockland's Animal Feed project just outside Uitenhage in the Eastern Cape is no exception.

Coming under the holding company, Sovereign Foods, this company is the biggest producer of poultry in the Eastern Cape, James Leslie, the technical operations manager at the mill says: "We decided to implement the new Adroit scada system in a project split between the different feed manufacturing processes. This has assisted us greatly in that we have become increasingly efficient through the experience of implementing the first stage and believe that the next phase will be significantly easier. Using the set-up wizards to design the different user interfaces became so simple that we even designed the screens for the next few phases well ahead of implementation."

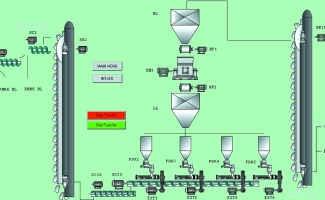

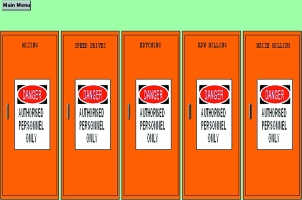

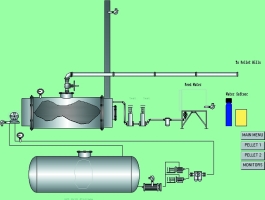

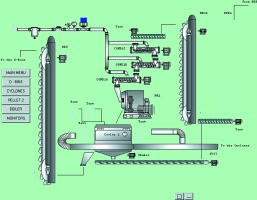

The project consists of three main parts: first the raw material batching section, secondly, the mixing and pelleting process and thirdly, the incoming 'raws' and distribution of the final product.

During the first phase it was decided to have the user interfaces not just in the main control room but also in the project office. The true value of the project office link is that the easy accessibility has assisted the engineers in becoming familiar with the systems flexible design wizards that assist them to produce high-quality three dimensional user interfaces, and gave them the advantage of being able to make changes to the system while it was live and running full production. The batching phase consists of approximately 150 tags mainly assigned to control screw conveyors and a 3-ton batching scale, attached to an LG programmable logic controller (PLC) unit via Ethernet cabling. The Adroit scada system Version 5.0 runs on a Windows XP Professional platform and the data is recorded in an Access database.

Implementation of the first phase alone has enabled the company to increase accuracy on the recipes of products it produces, which has a significantly large impact on their farms which has a total of 2 million birds at any given time. The future phases involve an upgrade which will consume a further 600 tags and will also mean the implementation of further user interfaces on the weighbridges that are currently in service to measure the approximately 7000 tons of finished product and all incoming raw materials. Alarms, redundancy and interfaces into an ERP system are all planned for the future phases. The pictures are all Screen grabs from the Rockland's scada system.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved